Laser Cleaning: Application of Industrial Laser Cleaning Technology

Applicable Substrates

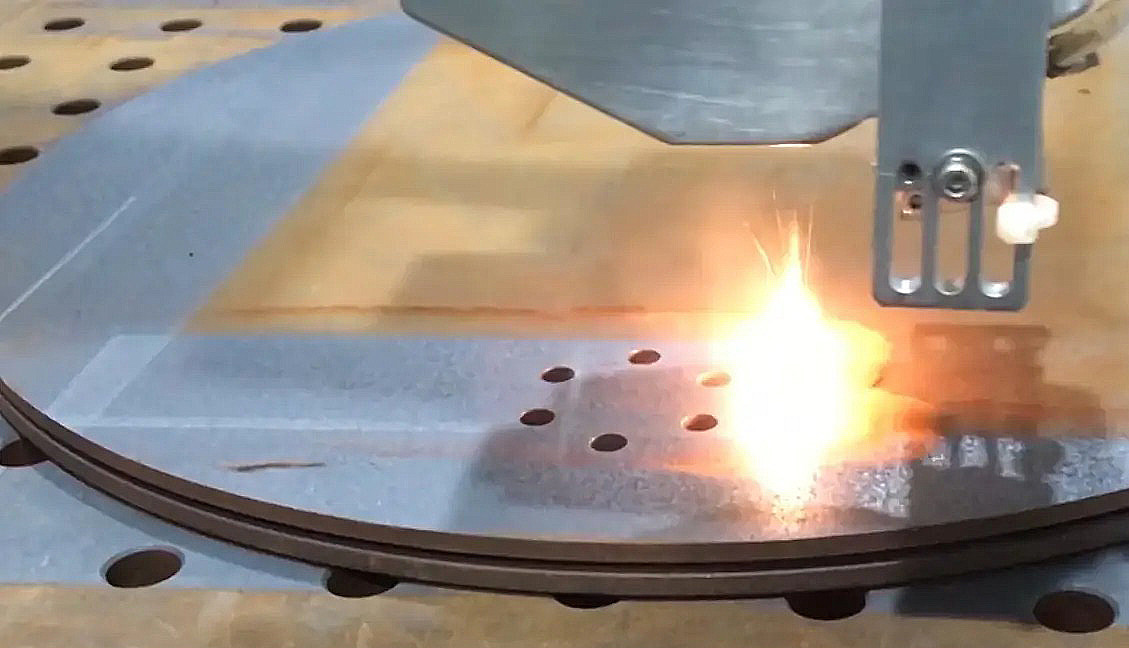

In the field of industrial application, the laser cleaning object is divided into two parts: substrate and cleaning material. The substrate mainly has the surface pollution layer of various metals, semiconductor chips, ceramics, magnetic materials, plastics and optical components. The cleaning material mainly includes the wide application needs of rust removal, paint removal, oil stain removal, film removal / oxide layer and resin, glue, dust and slag removal in the industrial field.

Advantages of Laser Cleaning

At present, the cleaning methods widely used in the cleaning industry include mechanical cleaning, chemical cleaning and ultrasonic cleaning, but their application is greatly limited under the constraints of environmental protection and the requirements of high-precision market. The advantages of laser cleaning machine are prominent in the application of various industries.

1. Automatic assembly line: the laser cleaning machine can be integrated with CNC machine tools or robots to implement remote control and cleaning, which can realize the automation of equipment and form product assembly line operation and intelligent operation.

2. Accurate positioning: use the optical fiber to transmit and guide the laser to make it flexible, and control the spot to move at high speed through the built-in scanning galvanometer, so as to facilitate the non-contact laser cleaning of the corners that are difficult to reach by the traditional cleaning methods, such as special-shaped parts, holes and grooves.

3. No damage: short-term impact will not heat the metal surface and will not damage the substrate.

4. Good stability: the pulse laser used in the laser cleaning machine has an ultra long service life, usually up to 100000 hours, stable quality and good reliability.

5. No environmental pollution: no chemical cleaning agent is required and no cleaning waste liquid is generated. The pollutant particles and gas generated in the process of laser cleaning can be simply collected and purified by portable exhaust fan to avoid environmental pollution.

6. Low maintenance cost: no consumables are consumed during the use of the laser cleaning machine, and the operation cost is low. In the later stage, only the lenses need to be cleaned or replaced regularly, with low maintenance cost and close to maintenance free.

Application industry

Typical applications of laser cleaning include: mold cleaning, industrial rust removal, old paint and film removal, pre welding and post welding treatment, ester removal of precision parts, decontamination and oxidation layer removal of electronic components, cultural relics cleaning, etc. Widely used in metallurgy, molds, automobiles, hardware tools, transportation, construction appliances, machinery and other industries.

Post time: Apr-11-2022