- Thepa e iketsang ea Laser Welding

- Mochini oa Welding oa Laser o tšoaroang ka letsoho

- Mochini oa ho itšeha ka Laser

- Mochini oa ho Seha oa Laser oa Size Precision Fiber e nyane

- Mochini oa ho itšeha oa Laser (3015 letoto)

- Fiber Laser Cutting Machine (6025 letoto)

- Mochini oa ho Seha ka Laser Bakeng sa Metal Sheet/Plate (ML-CB-3015FB)

- Tube Laser Cutting Machine (6016 Series)

- Mochini oa ho itšeha oa Tube Laser (QX letoto)

- Mochini oa ho hloekisa Laser

- Mochini oa ho tšoaea oa Laser

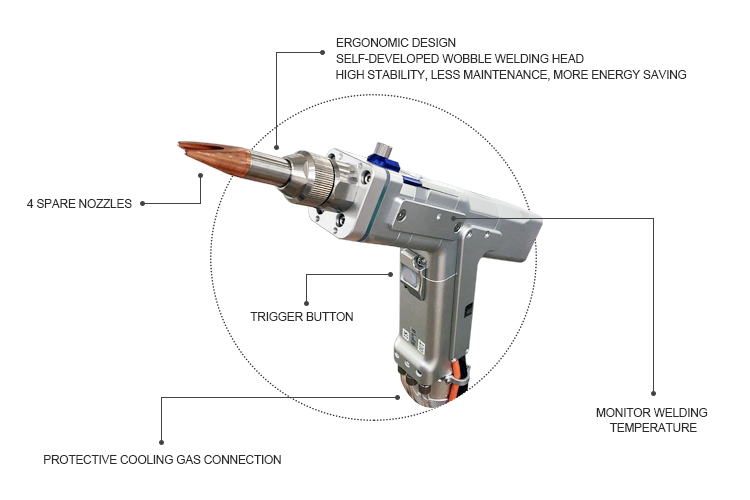

Mochini oa ho Welding Laser o Handhold (E Tloaelehileng)

Kenyelletso ea Sehlahisoa

Kaha e qalile ho qaptjoa ke Herolaser, mochini oa tjheseletsa o ts'oaretsoeng ka letsoho o tla ba teng ka moloko oa morao-rao oa fiber laser, othomathike ea terata e fepang le hlooho e sa tsoa ntlafatsoa ea welding, e etsang hore e be e ikhethang ka ho felletseng ho tlatsa lekhalo la 'maraka oa welding oa laser.

Ka litaelo tse bonolo, mochini o sebetsa letamong le phethahetseng la tjheseletsa ka nako e nepahetseng mme ha o hloke elektrode e ka jeoang, e nkang sebaka sa mokhoa oa ts'ebetso oa mechini ea khale ea tšepe ea arc holim'a poleiti e tšesaane ea tšepe e se nang tšepe, poleiti ea tšepe le poleiti ea masenke.Ka lebaka la ho feto-fetoha ha tjheseletsa ka libopeho tse sa tloaelehang tsa li-workpieces, mochine ona o sebelisoa haholo ka lik'habote le lisebelisoa tsa kichineng, litepisi tsa litepisi le li-lifti, liraka tsa mabenkele, lionto, mekoallo ea lemati le lifensetere, mabokose a kabo ea matla, thepa ea ka tlung ea tšepe e sa hloekang le liindasteri tse ling.

Mochine o amohela moralo o bonolo oa basebelisi le theknoloji e ntlafalitsoeng, ha e bapisoa le lisebelisoa tsa khale tsa ho tjheseletsa, ho etsa hore li-welders li sebetse ka mokhoa o atlehileng haholoanyane, o bolokehileng, oa ho boloka matla le tikoloho.Lebelo la tjheseletsa le potlakile ka makhetlo a 3 ho isa ho a 10 ho feta leha e le neng pele ha le ntse le sebetsa 'me le koahela likhakanyo tsa hau haholo.Herolaser handheld welding machine - etsa hore li-welders li rate mesebetsi ea bona le ho feta.

Tekheniki Parameters

| Matla a Laser | 1000W/1500W/2000W/3000W |

| Laser wavelength | 1070nm |

| Bolelele ba Fiber | Tlhophiso e tloaelehileng: 10M, tšehetso e phahameng: 15m |

| Mokhoa oa ts'ebetso | Tsoela pele/ Ketso ya ho fetofetoha |

| Lebelo la lebelo la mochini oa welding | 0-120 limilimithara/s |

| Mochini oa ho futhumatsa metsi | Tanka ea metsi ea thermostatic ea indasteri |

| Ambient Mocheso | 15 ~ 35 ℃ |

| Ambient Humidity | <70% ha ho condensation |

| Botenya ba tjheseletsa | 0.5-3 limilimithara |

| Litlhoko tsa lekhalo | ≤0.5mm |

| Voltage e sebetsang | AC220V |

| Boholo | 1100mm x 570mm x 1180mm |

| Boima ba 'mele | 220kg |

Likarolo tsa mantlha

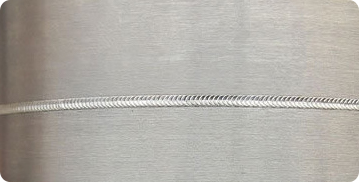

Theknoloji ea swing welding ea lenonyeletso le cheselitsoeng

The wobble welding joint e ntlafalitsoe ka boikemelo, ka mokhoa oa swing welding, bophara bo feto-fetohang le mamello e matla ea welding, e etsang hore ho be le moeko oa sebaka se senyenyane sa welding ea laser, e eketsa boholo ba mamello le bophara ba weld ea likarolo tsa ts'ebetso, 'me e fumana sebopeho se betere sa weld. .

1. Betere tjheseletsa formability le boleng bo phahameng letheba tjheseletsa

2. Fuselage le hlooho ea laser li na le litlhoko tse tlase tsa matla a laser

3. Sebaka se lumelletsoeng sa bophara ba weld se tla atolosoa, 'me weld e tla ba ntle ntle le deformation

4. Bokhoni bo botle ba aluminium alloy bonding, boleng bo phahameng ba ho sebetsana le ho pheta-pheta le botsitso

WOBBLE hlooho ea letsoho la laser, e bobebe ebile e tenyetseha, e khona ho tjheseletsa karolo efe kapa efe ea sesebediswa sa mosebetsi, ho etsa hore mosebetsi wa welding o sebetse hantle, o bolokehile, o baballang matla le tikoloho.

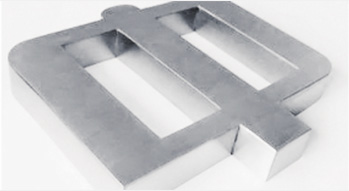

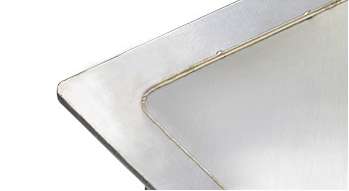

Ho chesoa ha fillet

Ho tjheseletsa seropeng

Welding ea seroki

Sebetsa ka ho roka

Likarolo tsa mochini oa tjheseletsa oa letsoho o pholileng ka metsi

E hahiloe ka bobeli-mocheso oa liindasteri tse peli tse laolang liindasteri.taolo ea kamehla ea mocheso le ho senya mocheso, ho etsa bonnete ba hore mocheso oa mocheso oa likaroloana tsa mantlha tsa optical circuit.Ka laser fiber, e tsitsitseng le e sebetsang hantle.

Sekrine sa ho ama se kopantsoeng

Ts'ebetso ea phanele ea lipuo tse ngata, e bonolo ho e utloisisa, ha ho na boiphihlelo bo hlokahalang, koetliso ea mahala, e bonolo ho e tseba

Fuselage e tiileng

Fuselage e entsoe ka thepa e thata, e tšoarellang, boleng bo ka tšeptjoang, tlhokomelo e fokolang le e tsitsitseng haholoanyane

10-15m optical fiber cable

Mohala oa 10-15m optical fiber o hlophisitsoe pakeng tsa hlooho ea laser le moamoheli, e loketseng bakeng sa welding ea mohala le ts'ebeliso e bonolo.

Maemo a Kopo

Mochini ona o tšoaroang ka letsoho oa laser o loketse ho cheselletsa khauta, silevera, titanium, nickel, tin, koporo, aluminium le tšepe e 'ngoe le lisebelisoa tsa eona tsa alloy, o ka fihlela ts'ebetso e ts'oanang e nepahetseng pakeng tsa tšepe le litšepe tse sa tšoaneng, e' nile ea sebelisoa haholo lisebelisoa tsa sefofane. , ho haha likepe, lisebelisoa, lihlahisoa tsa mechine le tsa motlakase, likoloi le liindasteri tse ling.

Tlhahlobo ea matla a ho tjheseletsa ka laser

| Matla a laser | 1000W | 1500W | 2000W | 3000W | 4000W | 6000W | 8000W | 10000W | 12000W | |

| Lintho tse bonahalang | botenya | |||||||||

| Ts'epe e sa beng le mabali | 1 | √ | √ | √ | √ | √ | √ | √ | √ | √ |

| 2 | √ | √ | √ | √ | √ | √ | √ | √ | √ | |

| 3 | √ | √ | √ | √ | √ | √ | √ | √ | ||

| 4 | √ | √ | √ | √ | √ | √ | √ | |||

| 5 | √ | √ | √ | √ | √ | √ | ||||

| 6 | √ | √ | √ | √ | √ | √ | ||||

| 8 | √ | √ | √ | √ | ||||||

| 10 | √ | √ | √ | |||||||

| 12 | √ | √ | ||||||||

| 15 | √ | |||||||||

| 20 | ||||||||||

| 25 | ||||||||||

| 30 | ||||||||||

| 40 | ||||||||||

| Tšepe ea carbon | 1 | √ | √ | √ | √ | √ | √ | √ | √ | √ |

| 2 | √ | √ | √ | √ | √ | √ | √ | √ | ||

| 3 | √ | √ | √ | √ | √ | √ | √ | |||

| 4 | √ | √ | √ | √ | √ | √ | ||||

| 5 | √ | √ | √ | √ | √ | |||||

| 6 | √ | √ | √ | √ | ||||||

| 8 | √ | √ | √ | √ | ||||||

| 10 | √ | √ | √ | |||||||

| 12 | √ | √ | √ | |||||||

| 15 | √ | √ | ||||||||

| 20 | √ | |||||||||

| 25 | ||||||||||

| 30 | ||||||||||

| 40 | ||||||||||

| Aluminium | 1 | √ | √ | √ | √ | √ | √ | √ | √ | √ |

| 2 | √ | √ | √ | √ | √ | √ | √ | √ | ||

| 3 | √ | √ | √ | √ | √ | √ | √ | |||

| 4 | √ | √ | √ | √ | √ | √ | ||||

| 5 | √ | √ | √ | √ | √ | |||||

| 6 | √ | √ | √ | √ | ||||||

| 8 | √ | √ | ||||||||

| 10 | √ | |||||||||

| 12 | ||||||||||

| 15 | ||||||||||

| 20 | ||||||||||

| 25 | ||||||||||

| 30 | ||||||||||

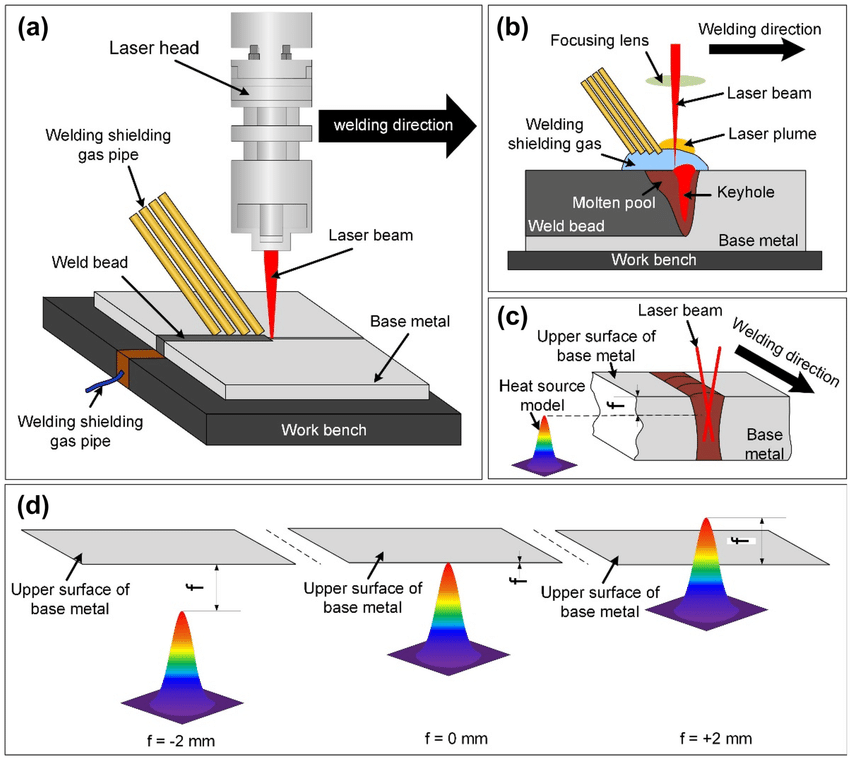

Setšoantšo sa moralo oa ts'ebetso ea welding ea laser:

Mefuta e fapaneng ea laser welding:

| Mofuta oa laser | Wavelength | Mokhoa oa ho tsoa | Kopo |

| CW fiber laser | 1070nm | Tsoelang pele | tjheseletsa nako le nako / e tsoelang pele ea tšepe e tšoanang Modulated pulse spot welding |

| laser ea YAG | 1064nm | Pulse | Spot welding/weld seam applications tsa tšepe e tšoanang |

| QCW fiber laser | 1070nm | Pulse/ E tsoelang pele | Metal Spot Welding / Continuous Seal Welding |

| Laser ea semiconductor | 808nm, 915nm, 980nm | Pulse/ E tsoelang pele | Plastiki Welding / Laser Soldering |

HEROLASER Lethathamo la Sehlahisoa sa Lisebelisoa tsa Laser tse Bohlale

Bakeng sa ho reka ka bongata kapa lihlahisoa tse ikhethileng, ka kopo ikopanye le litšebeletso tsa bareki ba inthaneteng, kapasiea molaetsa.

U ka boela ua romela imeile hosales@herolaser.net.