- Izixhobo ze-Laser Welding ezizenzekelayo

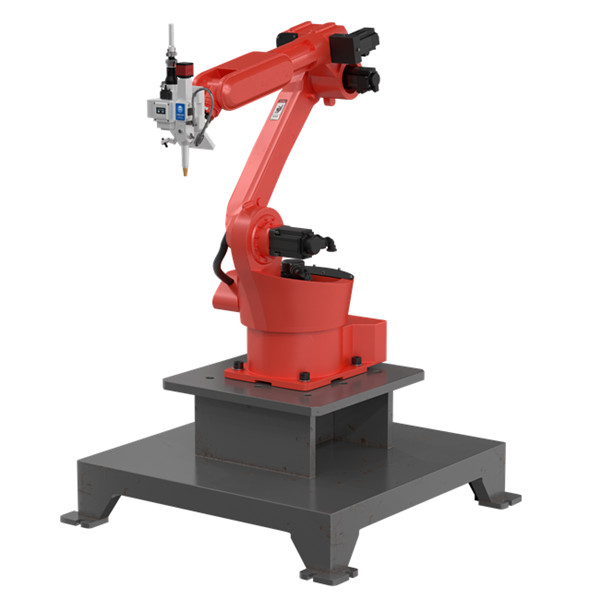

- I-Automatic Fiber Laser Welding Robot

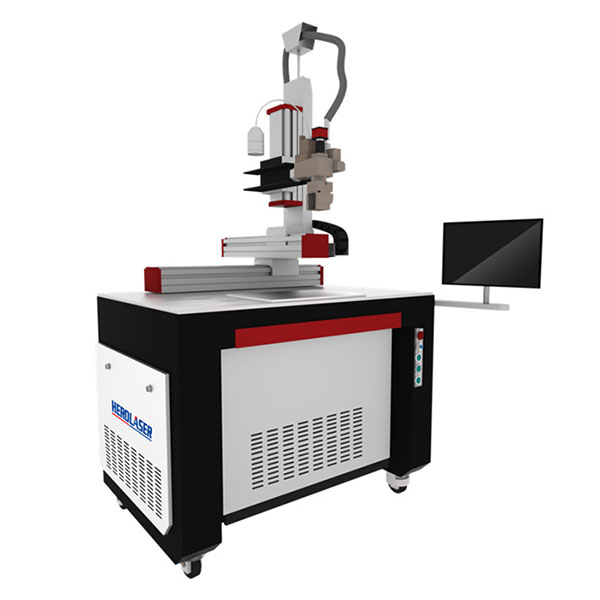

- 3/4/6 Axis Umatshini wokuWelding weLaser ozenzekelayo

- Amandla aphezulu 12KW Laser Welding Machine

- Ukulungisa uMngundo i-YAG Laser Welding Machine

- Isikhululo esiphindwe kabini sobushushu obungaguqukiyo kumatshini wokuthambisa we-laser

- Iiglasi umatshini welding oluzenzekelayo laser

- Umatshini wokuWelding weLaser ophathwa ngesandla

- Umatshini wokusika iLaser

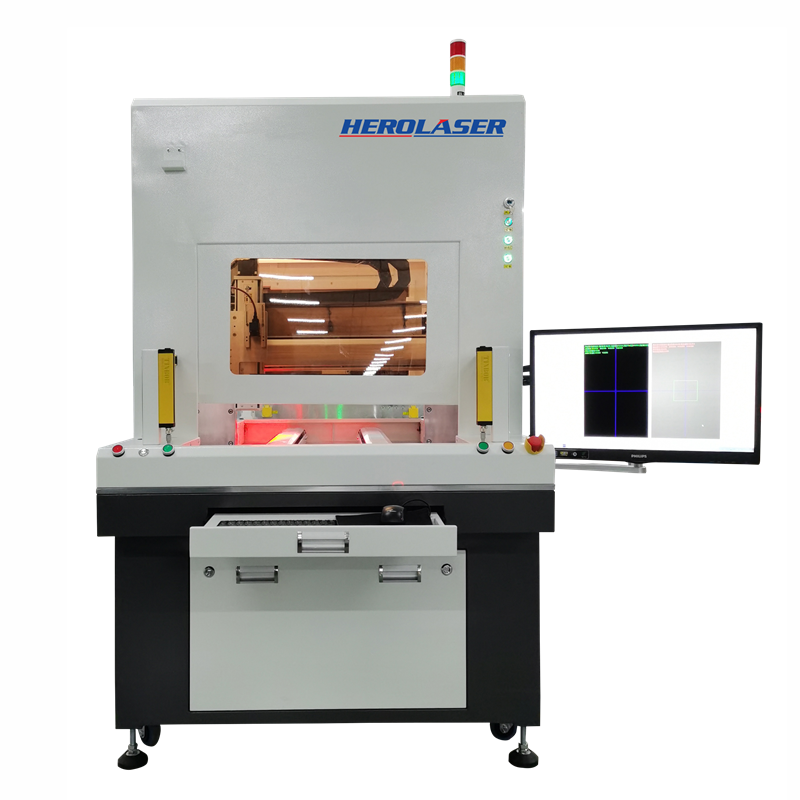

- Ubungakanani obuNcinci obuCwangcisiweyo beFiber Laser Cutting Machine

- Umatshini wokusika iFayibha Laser (3015 series)

- IFayibha Laser Cutting Machine (6025 series)

- ILaser Cutting Machine yeMetal Sheet/Plate (ML-CB-3015FB)

- Tube Laser Cutting Machine (6016 Series)

- Umatshini wokusika umbhobho weLaser (QX series)

- Umatshini wokucoca ngeLaser

- Umatshini wokuMakisha weLaser

Isikhululo esiphindwe kabini sobushushu obungaguqukiyo kumatshini wokuthambisa we-laser

Intshayelelo yeMveliso

Isixhobo sineendlela zokusebenza ezininzi kunye nenkqubo yokutya okuzenzekelayo ngocingo okanye isixhobo sokuhambisa i-solder esichanekileyo esichanekileyo sokuhambisa isixhobo sokuthengisa ngokugqibeleleyo kwiimeko ezahlukeneyo.Kwiimveliso ezithile ezichanekileyo ezingenakukwazi ukujongana ne-reflow soldering kunye ne-wave soldering machine, umatshini we-laser soldering uya kuba yinto yakho ethembekileyo yokuthengisa iimveliso zakho ezinikwe iimpawu zesakhiwo esizinzile, ukuphumelela kweendleko, ukusebenza okuphezulu kwe-soldering kunye ne-teknoloji yokulawula amanani.

| IParameter yobuGcisa | ||

| Hayi. | Into | Ipharamitha |

| 1 | Umzekelo | I-ML-WS-XF-ZD2-HW80 |

| 2 | Amandla eLaser | 60W-200W |

| 3 | Uhlobo lweLaser | isemiconductor |

| 4 | Ubude bengqwalasela | 80/125/160mm(ngokuzikhethela) |

| 5 | Uluhlu lolawulo lobushushu | 60°C-400°C |

| 6 | Ukuchaneka kweNkqubo yobushushu | ±( 0.3% ukufunda + 2°C) (ubushushu be-ambient 23±5°C) |

| 7 | IGPS | ICoaxial CCD esweni kunye indawo yeCCD |

| 8 | Ubungakanani besixhobo | 1100mm*1450mm*1750mm |

| 9 | Uluhlu lwe-welding | 250mm * 250mm(isikhululo esisodwa sokusebenza) |

| 10 | Ukutya istroke | 1000mm |

| 11 | Inani leezembe ezishukumayo | 6 izembe(X1 Y1 Z1/X2 Y2 Z2) |

| 12 | Ukuphindaphinda | ±0.02mm |

| 13 | Inkqubo yokususa uthuli | Inkqubo yokucoca i-soot ezenzekelayo |

| 14 | Ubunzima obupheleleyo | 350Kg |

| 15 | Amandla onke | ≤2.5KW |

Iimpawu eziphambili

1. Yamkela i-laser semiconductor laser, esebenza ngendlela engasebenziyo.

2. Akukho ukusetyenziswa kwentsimbi ye-soldering, ehamba ngexabiso eliphantsi kunye nokugcinwa okulula.

3. Indawo yesoda ebonwayo ngokusetyenziswa kwe-Dual vision application kunye nenkqubo yokubeka iliso yeCCD.

4. I-Laser icutshungulwa phantsi kobushushu obungaguqukiyo ngempendulo yangaphakathi evaliweyo yokubeka iliso lobushushu ngexesha langempela.

5. Indawo ye-welding inokulungelelaniswa ukuhlangabezana nobukhulu obuhlukeneyo be-soldering.

6. Beka inkqubo yokucoca umsi ukususa kwangethuba intsalela evuthayo ekutshayo.

7. Ukhetho lokutshintshela phakathi kwesitishi esinye kunye nemodi yesitishi esiphindwe kabini.

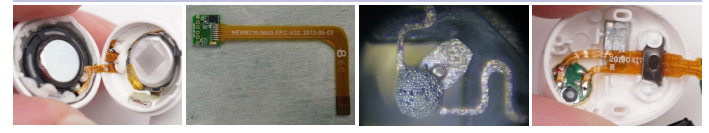

Isampulu yokuBonisa

cela elona xabiso lilungileyo

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu