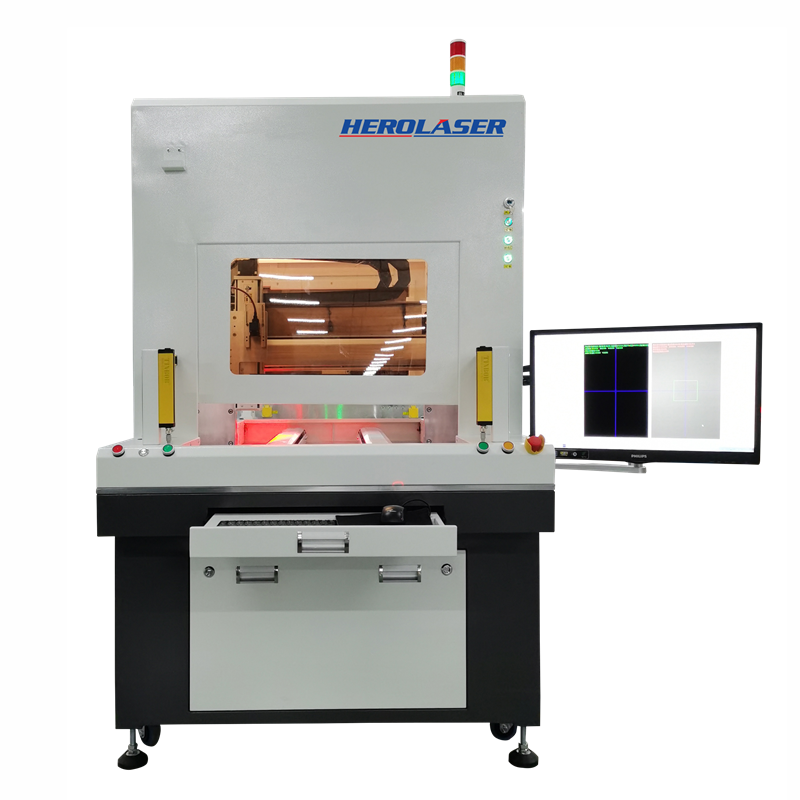

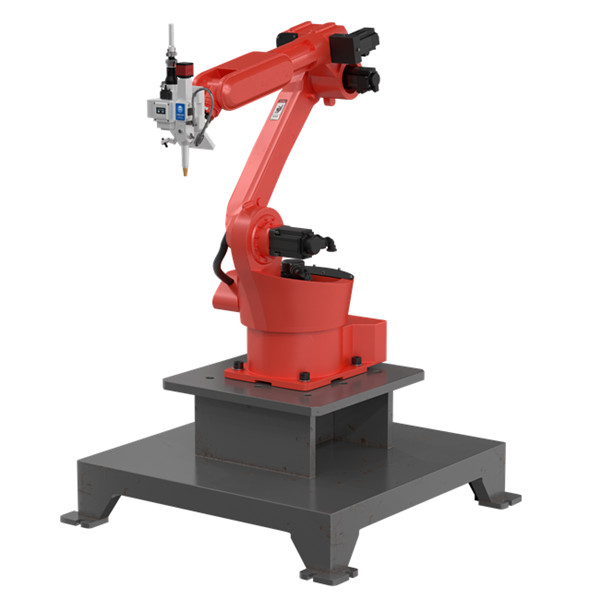

- I-Automatic Laser Welding Equipment

- I-Handheld Laser Welding Machine

- Laser Cutting Machine

- Umshini Wokusika I-Laser Usayizi Omncane Precision Fiber

- Umshini wokusika we-Fiber Laser (uchungechunge lwe-3015)

- I-Fiber Laser Cutting Machine (uchungechunge lwe-6025)

- Umshini Wokusika I-Laser Weshidi Lensimbi/I-Plate (ML-CB-3015FB)

- I-Tube Laser Cutting Machine (6016 Series)

- Tube Laser cutting machine (QX series)

- Umshini Wokuhlanza I-Laser

- Umshini Wokumaka we-Laser

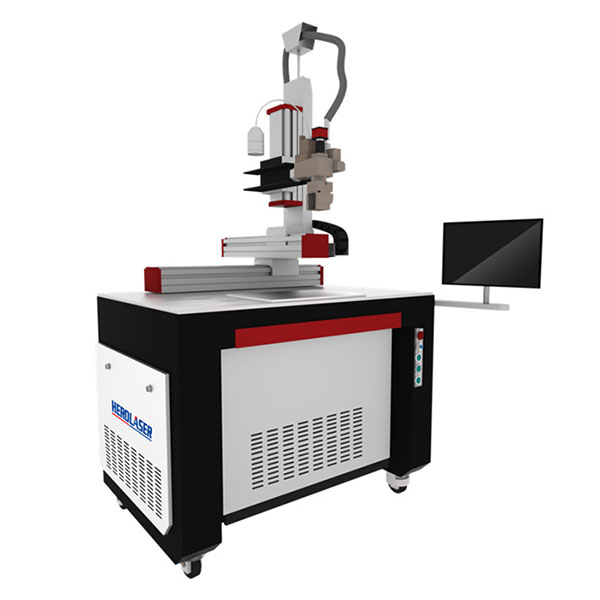

Umshini wokushisa ongaguquki we-laser wesiteshi esiphindwe kabili

Isingeniso Somkhiqizo

Isisetshenziswa sinezinhlobo eziningi zokusebenza kanye nesistimu yokuphakela izintambo ezizenzakalelayo noma idivayisi yokusabalalisa yokunamathisela ngokunemba kwe-solder ukuze ithengise kahle ngezikhathi ezahlukene.Ngemikhiqizo ethile enembile engakwazi ukucubungula nge-reflow soldering kanye nomshini we-wave soldering, umshini we-laser soldering uzoba inketho yakho ethembekile yokuthengisa imikhiqizo yakho uma unikezwe izici zesakhiwo esizinzile, ukuphumelela kwezindleko, ukusebenza kahle okuphezulu kwe-soldering kanye nobuchwepheshe bokulawula izinombolo.

| Ipharamitha Yezobuchwepheshe | ||

| Cha. | Into | Ipharamitha |

| 1 | Imodeli | I-ML-WS-XF-ZD2-HW80 |

| 2 | Amandla e-laser | 60W-200W |

| 3 | Uhlobo lwe-laser | i-semiconductor |

| 4 | Gxila ubude bokugxila | 80/125/160mm(ngokuzikhethela) |

| 5 | Ibanga lokulawula izinga lokushisa | 60°C-400°C |

| 6 | Ukunemba Kwesistimu Yezinga Lokushisa | ±( 0.3% ukufunda + 2°C) (izinga lokushisa elizungezile 23±5°C) |

| 7 | I-GPS | ICoaxial CCD ukuqapha kanye indawo ye-CCD yendawo |

| 8 | Usayizi wesisetshenziswa | 1100mm*1450mm*1750mm |

| 9 | Ibanga lokushisela | 250mm * 250mm(indawo yokusebenza eyodwa) |

| 10 | Ukondla unhlangothi | 1000mm |

| 11 | Inombolo yezimbazo ezinyakazayo | 6 izimbazo(X1 Y1 Z1/X2 Y2 Z2) |

| 12 | Ukuphindaphinda | ±0.02mm |

| 13 | Uhlelo lokususa uthuli | Isistimu yokuhlanza insipho ezenzakalelayo |

| 14 | Isisindo Esiphelele | 350Kg |

| 15 | Amandla aphelele | ≤2.5KW |

Izici ezibalulekile

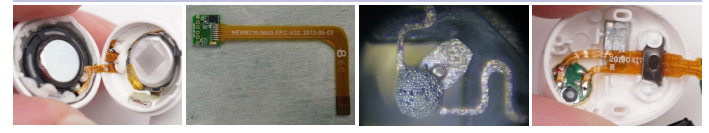

1. Yamukela i-semiconductor laser, esebenza ngendlela yokucubungula okungeyena othintana naye.

2. Akukho ukusetshenziswa kwethiphu ye-soldering iron, esebenza ngezindleko eziphansi kanye nokugcinwa okulula.

3. Iphuzu le-solder lokuma elibonakalayo nge-Dual vision application kanye nohlelo lokuqapha lwe-CCD.

4. I-Laser icubungula ngaphansi kwezinga lokushisa elingashintshi ngempendulo yangaphakathi ye-loop evaliwe yokuqapha izinga lokushisa kwesikhathi sangempela.

5. Indawo yokushisela ingalungiswa ukuze ihlangabezane nosayizi abahlukahlukene bokunamathisela.

6. Faka isistimu yokuhlanza intuthu ukuze isuse kusenesikhathi izinsalela ezivuthayo ekushisweni.

7. Ongakukhetha ukushintsha phakathi kwesiteshi esisodwa kanye nemodi yesiteshi se-Double.

Isibonisi Sesampula

cela intengo engcono kakhulu

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu