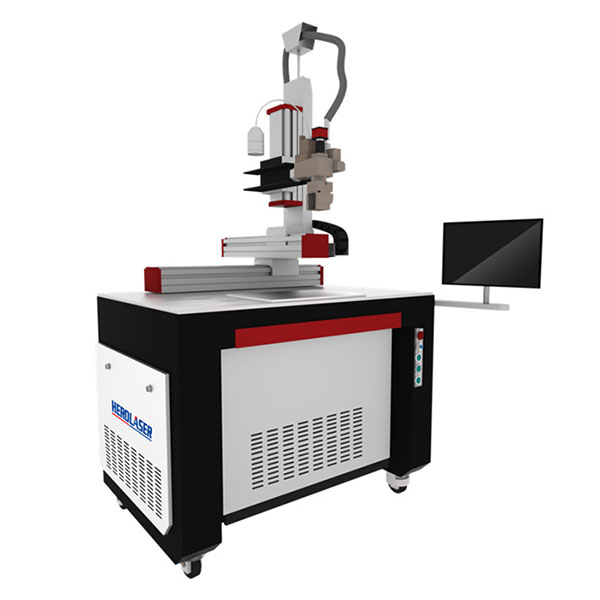

- I-Automatic Laser Welding Equipment

- I-Handheld Laser Welding Machine

- Laser Cutting Machine

- Umshini Wokusika I-Laser Usayizi Omncane Precision Fiber

- Umshini wokusika we-Fiber Laser (uchungechunge lwe-3015)

- I-Fiber Laser Cutting Machine (uchungechunge lwe-6025)

- Umshini Wokusika I-Laser Weshidi Lensimbi/I-Plate (ML-CB-3015FB)

- I-Tube Laser Cutting Machine (6016 Series)

- Tube Laser cutting machine (QX series)

- Umshini Wokuhlanza I-Laser

- Umshini Wokumaka we-Laser

Ukulungisa Isikhunta Umshini Wokushisela I-YAG Laser

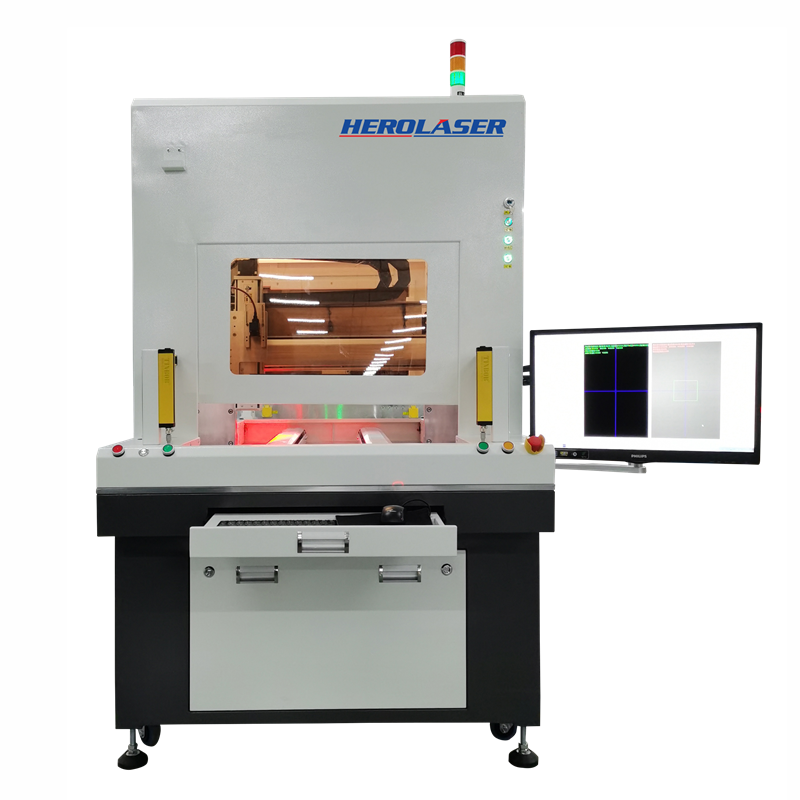

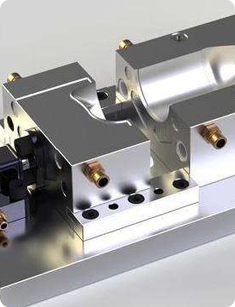

Isingeniso Somkhiqizo

I-Herolaser mold ukulungisa uchungechunge lwemishini yokushisela i-laser ikhethekile ekusebenzeni kwemboni yesikhunta, le modeli enikezelwe esikhundleni se-argon welder yendabuko yokulungisa isikhunta esinembayo.Zonke izingxenye ezibalulekile zalo mshini zingenisiwe.Uhlelo lokusebenza lwesoftware lusebenzisa isikrini esikhulu se-LCD futhi lubonisa isixhumi esibonakalayo sezilimi eziningi, silula futhi kulula ukusisebenzisa ku-opharetha.Imodi yokusebenza yokusetha ngaphambilini eminingi, futhi ingahlela ngabasebenzisi, umsebenzi wenkumbulo unomphela, osebenza ezintweni ezahlukahlukene.

Ifakwe uhlelo olukhethekile lokubuka isibonakhulu, ukukhuliswa okungu-10x;Kukhona idivayisi yokuvikela isihlungi se-elekthronikhi enesivinini esikhulu ukuvikela amehlo omsebenzisi emonakalweni we-laser, ukunciphisa ukukhathala kwamehlo omsebenzisi futhi kuthuthukise ukusebenza kahle.

Uhlelo lokuvikela i-argon oluvumelanayo olunokulawulwa kwe-microcomputer yangaphakathi lungavimbela i-weld ekubeni i-oxidized futhi yenze ukushisela kuqine futhi kube kuhle;I-Argon ingasindiswa ngezinga elikhulu kakhulu ngokwamukela ukulawula okuvumelanayo nge-laser emission

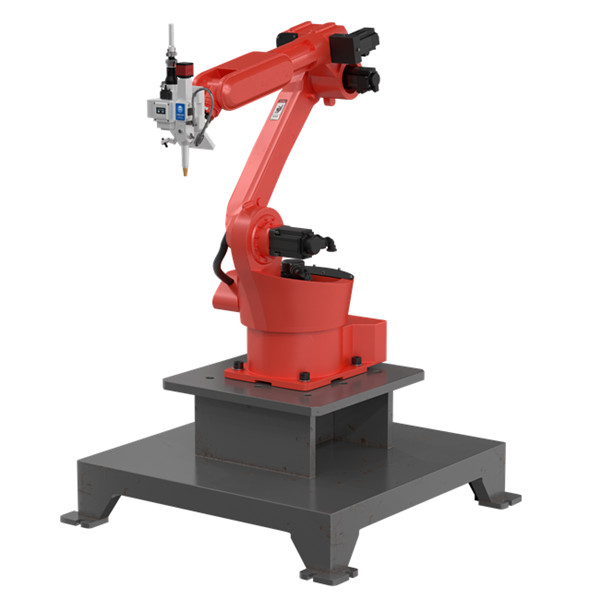

Ithangi lamanzi lomshini wokushisela we-laser we-robot lingashisa futhi lipholise umshini, futhi liqaphe izinga lokushisa lamanzi ngesikhathi sangempela.Inesimo sokushisa esiqhubekayo / sokujikeleza

Ikhabethe le-laser host lingakwazi ukubona ngokucacile ukuma komkhiqizo kanye nomphumela wokushisela ngokuvumelana nenkomba yokukhanya okubomvu

Ibhentshi lokusebenzela lomshini omkhulu kanye nendawo lapho i-welding workpiece ibekwe khona ilungele ukuthi i-laser ishisele isiqeshana sokusebenza.

Imingcele Yezobuchwepheshe

| Imodeli: | I-ML-WY-BP-DB-W200 | I-ML-WY-BP-DB-W400 |

| I-3-axis stroke yebhentshi lomsebenzi | X=300mm,Y=200mm(X,I-Y ingalungiswa ngesandla futhi i-z-axis ingaphakanyiswa) | |

| Ukwakhiwa kwebhentshi lomsebenzi | ≤200KG | |

| Ukunikezwa kwamandla kagesi | 220V±10%/50Hz Noma 380V±10%/50Hz | |

| Laser nemingcele | ||

| Uhlobo lwe-laser | Nd:Ukushaya kwenhliziyo kwe-YAG | |

| Ilungisa ububanzi bendawo yokukhanya | 0.1~0.3mm | |

| Usayizi wendawo ekhanyayo | 0.2-3.0mm | |

| Laser wavelength | 1064nm | |

| Ububanzi be-Pulse | 0.5~25ms | |

| Amandla we-laser aphezulu | 200W | 400W |

| Imvamisa ye-Pulse | ≤50Hz | |

| Ubude bokugxila kokuphuma kwe-laser | 80mm/100mm/120mm(uyazikhethela) | |

| Ukupholisa i-laser | Ukupholisa amanzi | |

| Isistimu yokubuka | Isibonakhulu (360° iyalungiseka) | |

| Igesi yokuvikela | Umugqa owodwa (xenon) | |

| Ipharamitha ye-Solder | ||

| I-Welding wire diameter | 0.1mm~0.8mm | |

Izici ezibalulekile

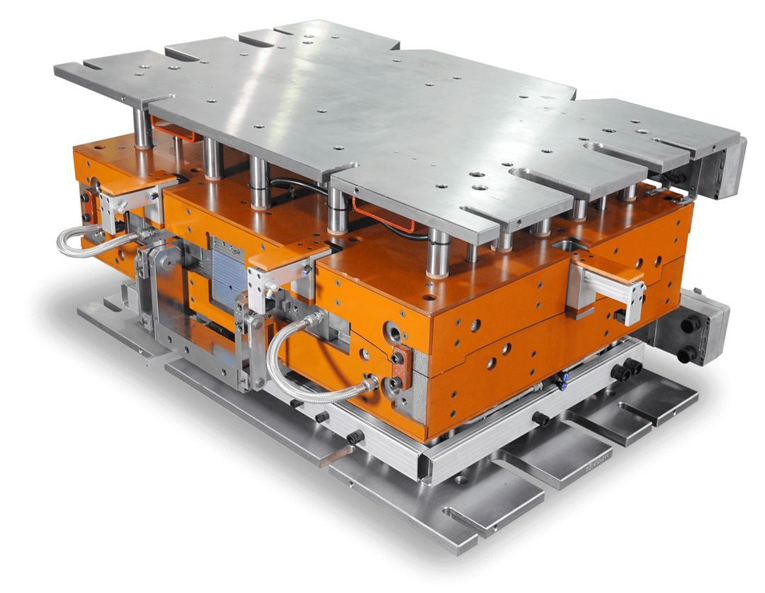

1. Indawo ethintekile ekushiseni incane, i-deformation encane yokubumba okunembayo.

2. Ukujula kwe-Welding kukhulu, ukushisela ngokuqinile.Ukuhlanganiswa okwanele, akukho mikhondo yokulungisa.Azikho izenzakalo ze-dimple ekuhlanganiseni ukuma kwezingxenye zokuqagela kanye nengxenye eqhumayo yezinto ezincibilikayo zechibi elincibilikisiwe.

3. Izinga le-oxidation eliphansi, umbala wezingxenye zokucubungula uphelele.

4. Akukho stomata noma umgodi wesihlabathi owanyamalala ngemva kokushisela.

5. Izingxenye zokushisela zingacutshungulwa, ikakhulukazi ezifanele izidingo zokupholisha zokulungisa isikhunta.

6. Izingxenye zokucubungula zingafinyelela ku-50 kuya ku-60 ubulukhuni be-Rockwell.

Akukho deformation of Welding die

Indawo ethintekile ekushiseni incane, engeke iholele ekushintshashintsheni kokufa okunembayo, futhi akukho ukucindezeleka endaweni ehlangene phakathi kwengxenye ye-convex yezinto ezincibilikisiwe echibini elincibilikisiwe kanye ne-matrix.

● Izinga le-oxidation liphansi futhi umsebenzi ngeke ushintshe umbala ngemva kokushisela

● Indawo yokushisisa incane, futhi izingxenye zomshini ngeke ziwohloke

● Ngeke kube khona izimbotshana noma i-trachoma ngemva kokushisela

● Ngemva kokushisela, ingabhalwa ngaphandle kokuthinta umphumela

Izimo zohlelo lokusebenza

Imboni yesikhunta

Ukusebenza ngensimbi

Ukukhiqiza imishini

Amavidiyo Nezindaba zalo mkhiqizo

Umshini Welding Laser

ngomhlaka-21 Ephreli, 2022

Umshini Welding Laser

ngomhlaka-21 Ephreli, 2022

Umshini Welding Laser

ngomhlaka-21 Ephreli, 2022

cela intengo engcono kakhulu

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu