- Thepa e iketsang ea Laser Welding

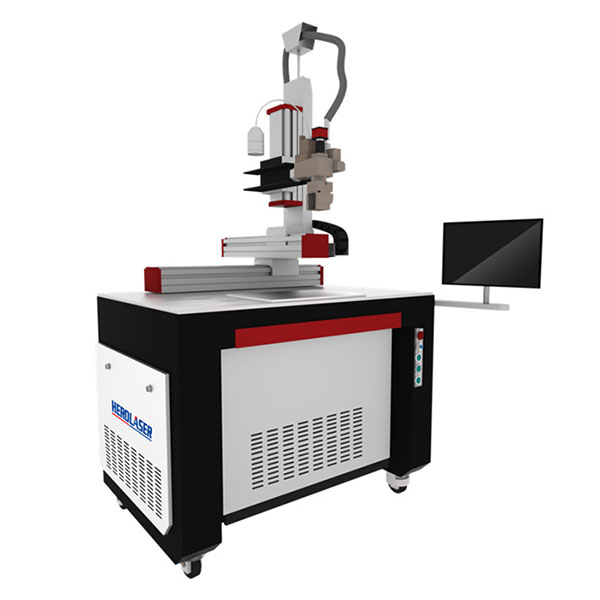

- Mochini oa Welding oa Laser o tšoaroang ka letsoho

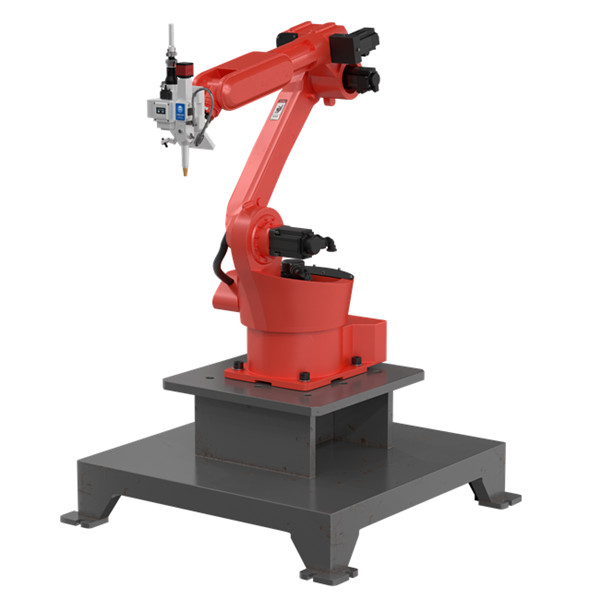

- Mochini oa ho itšeha ka Laser

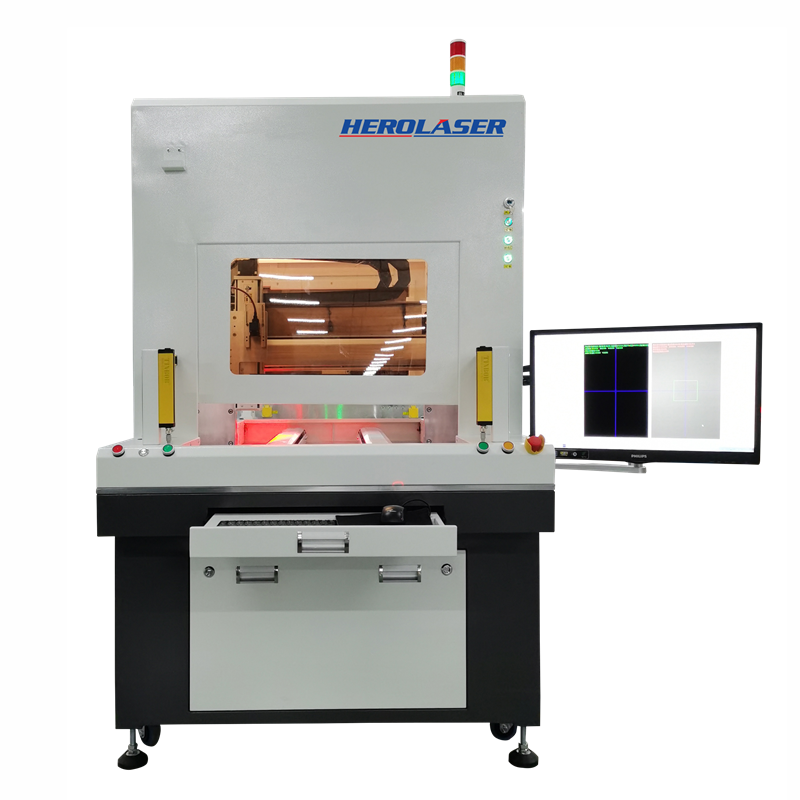

- Mochini oa ho Seha oa Laser oa Size Precision Fiber e nyane

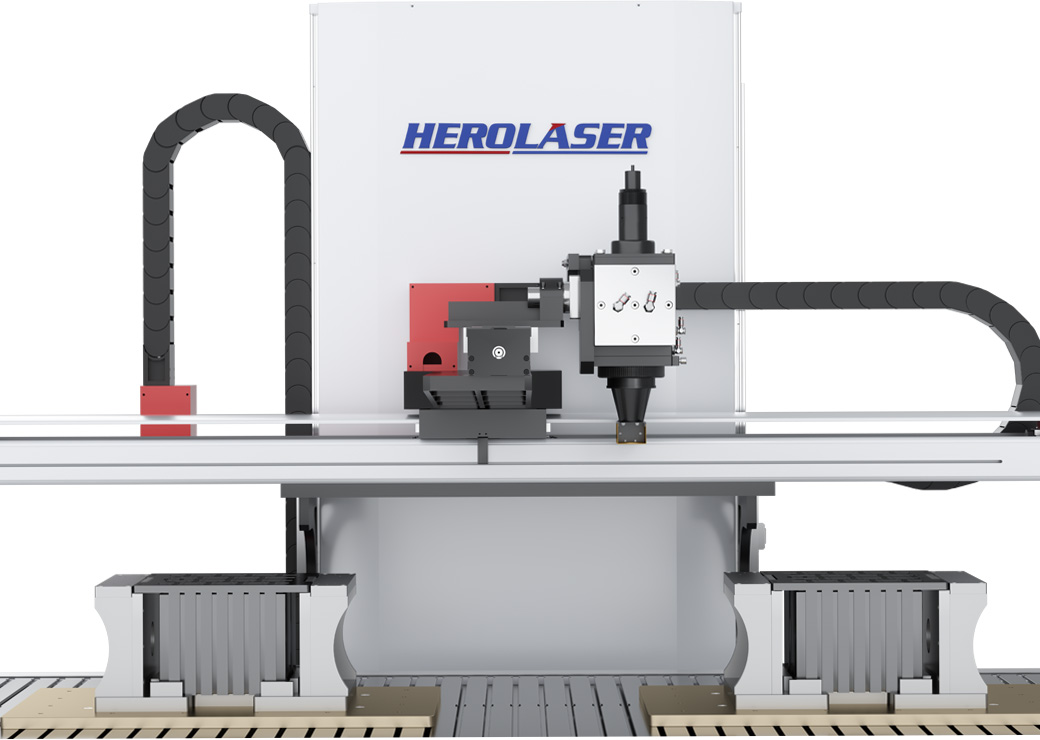

- Mochini oa ho itšeha oa Laser (3015 letoto)

- Fiber Laser Cutting Machine (6025 letoto)

- Mochini oa ho Seha ka Laser Bakeng sa Metal Sheet/Plate (ML-CB-3015FB)

- Tube Laser Cutting Machine (6016 Series)

- Mochini oa ho itšeha oa Tube Laser (QX letoto)

- Mochini oa ho hloekisa Laser

- Mochini oa ho tšoaea oa Laser

Mochini oa welding oa likhalase tsa laser

Kenyelletso ea Sehlahisoa

Mochini o ka cheseletsa litselana tse sa reroang ho tloha ntlheng e le 'ngoe le mola o otlolohileng ho ea ho curve trajectory holim'a lethathamo la lisebelisoa tse kang aluminium, carbon steel, tšepe e sa hloekang, koporo, li-alloys joalo-joalo ka li-jigs le lisebelisoa bakeng sa welding e tsitsitseng le e bonolo.Mochini oa welding oa likhalase tsa laser o hlophisitsoe ka ho khetheha bakeng sa indasteri ea likhalase ka pula ea mashome a lilemo a boiphihlelo ka likhalase le lipatlisiso le nts'etsopele ea mochini o tjheseletsang sethala.

| Tekheniki Parameter | |

| Matla a laser | 1000W |

| Boemo | 930mm *970mm*1900mm (L*W*H) |

| Sebaka sa ts'ebetso | X axis:500mm Y axis:300mm Z axis:300 limilimithara |

| Lebelo la ho matha | X axis:200mm/s Y axis:200mm/s Z axis:90mm/s |

| Pheta-pheta | ± 0.02 limilimithara |

| Mofuta oa fiber | Fiber e sa tloaelehang ea lefats'e |

| Laser wavelength | 1070±10nm |

| Boholo ba maqhubu a ho otla ha pelo | 5000Hz |

| Hlooho ea tlhahiso ea fiber | QBH |

| Bolelele ba fiber | 10-20m |

| Fiber core bophara | 50μm |

| Mokhoa oa ho sebetsa | E tsoelang pele/e fetohang |

| Bophelo bohle ba laser | > lihora tse 100,000 |

| Mokhoa oa ho pholisa | Pholiso ea metsi |

| Ho lebela | Pontšo ea leseli le khubelu le sistimi ea ho shebella ea CCD |

| Ho hlokahala matla | AC 220/380V 50Hz |

| Karolelano ea tšebeliso ea matla | 4.6kW |

| Maikutlo: 1. Laser ea referense ke Max photonics laser, tanka ea metsi ke tanka e khethehileng ea metsi, 'me sesebelisoa sa mochine ke mochini o tloaelehileng oa ho tjheseletsa oa laser; 2. Litekanyetso tse tafoleng ena ke tsa litšupiso feela, 'me thepa ea sebele ea ho fana ka thepa e tla ba teng. | |

Likarolo tsa mantlha

1. Mochine o tla boemong bo botle ba ho sebetsa mme o nka mehato e seng mekae feela ho phethela ts'ebetso ea ho kenya, e tšoanang le ea ho ithuta le ho sebetsa ha software.

2. Mochini o sebetsa ka lebelo le batlang le le holimo le lebelo le nepahetseng nakong ea ho tjheseletsa, e leng se etsang hore o atlehe haholo oa ho cheselletsa.

3. Workpiece e ke ke ea etsahala haholo hore e ka holofala ho tsoa ho welding ka lebaka la sebaka se lekanyelitsoeng sa sebaka se amehileng ke mocheso.

4. Mochine o sebetsa ka seam ea ho tjheseletsa ka sebopeho le botle ka bophara le botebo bo tsitsitseng, e leng ho bolokang nako ea ho o sila le ho bentša ka mor'a moo.

5. Tšebeliso ea matla ea fiber laser e batla e le tlaase, moo tekanyo ea phetoho ea photoelectric e fetang 35%.

6. Lisebelisoa tsa optical li tšoarella ka nako e telele 'me ha e le hantle ha li na tlhokomelo bakeng sa tšebeliso e akaretsang.

7. Mochine o na le mokhoa oa ho ipholisa o ikemetseng, o potolohang metsi ho fetisetsa mocheso ka hare ho fiber laser, ha ho na metsi a hlokahalang ho tsoa ka ntle.

8. Sethala sa tjheseletsa se fana ka ho kenya mefuta efe kapa efe ea li-jigs le lisebelisoa haeba ho hlokahala.

Bokhoni bo phahameng, makhetlo a 10 ka potlako

Ts'ebetso ea phanele ea lipuo tse ngata, e bonolo ho e utloisisa, ha e na boiphihlelo, koetliso ea mahala, e bonolo ho e tseba

Ts'ebetso e matla le boleng bo botle

Mochini o tiile ebile oa tšoarella, o na le boleng bo botle, 'me o khona ho ikamahanya le tjheseletso ea thepa e fapaneng le li-angles le bolelele bo fapaneng.

Sebopeho sa ts'ebetso ea pono

Ka ponts'o e bohlale, ponts'o e na le botlalo ebile e hlakile ha u habanya feela, 'me ts'ebetso e bonolo le ho feta

Mohlala oa Pontšo

kopa theko e ntle ka ho fetisisa

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu