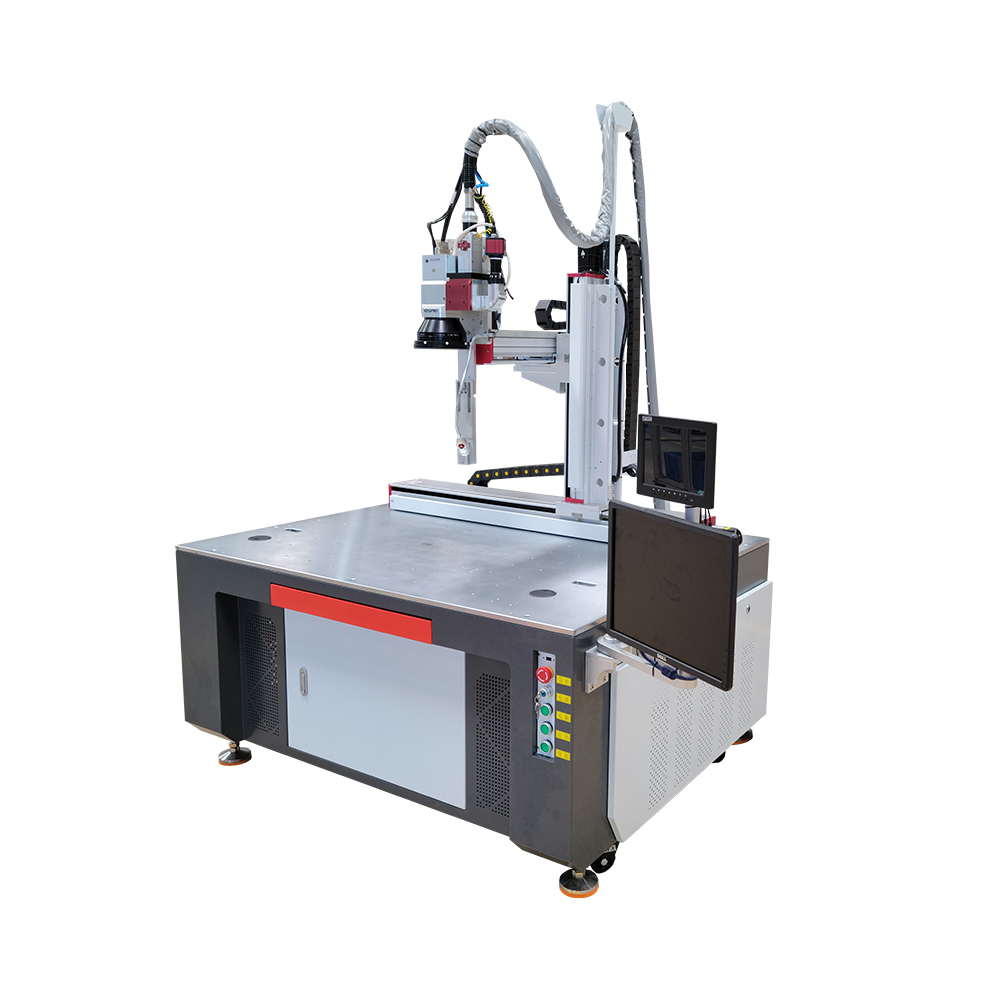

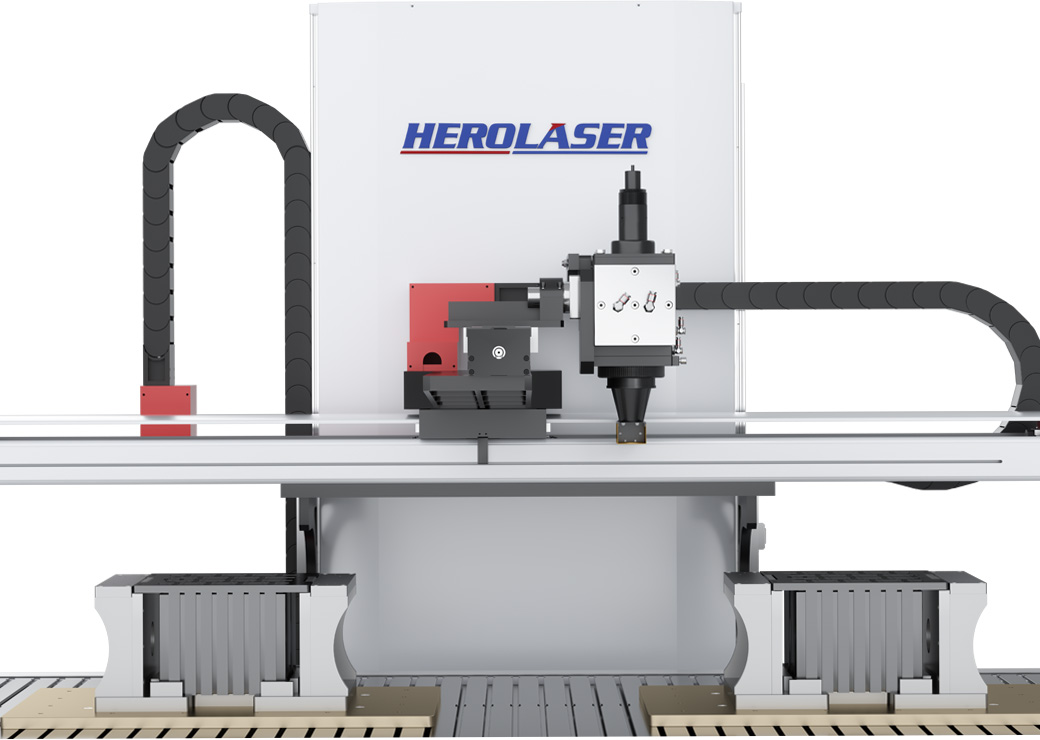

Glasses laser automatic welding machine

Product Introduction

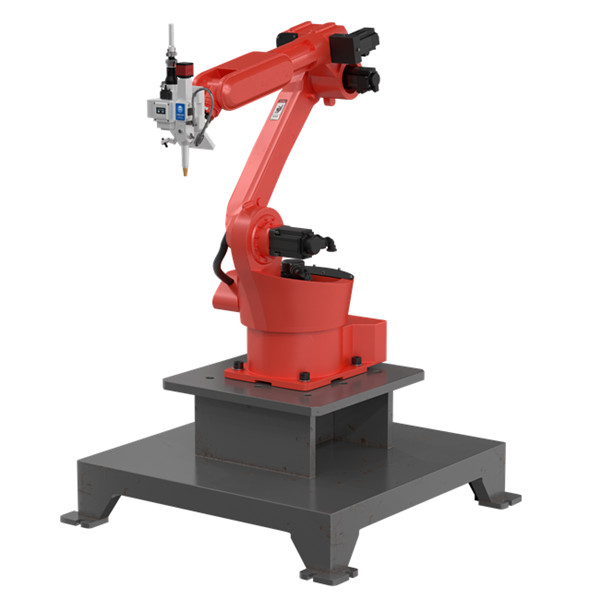

The machine can weld any random paths from single point and straight line to curve trajectory upon a list of materials like aluminum, carbon steel, stainless steel, copper, alloys etc. with jigs and fixtures for fixed and flexible welding. The Glasses laser automatic welding machine is specially developed for the glasses industry with the precipitation of decades of welding experiences in glasses and research and development of platform automatic welding machine.

|

Technical Parameter |

|

| Power of laser |

1000W |

| Dimension |

930mm *970mm*1900mm (L*W*H) |

| Operating range |

X axis:500mm Y axis:300mm Z axis:300mm |

| Running speed |

X axis:200mm/s Y axis:200mm/s Z axis:90mm/s |

| Repeatability |

±0.02mm |

| Type of fiber |

Rare earth doped fiber |

| Laser wavelength |

1070±10nm |

| Maximum pulse frequency |

5000Hz |

| Fiber output head |

QBH |

| Fiber length |

10-20m |

| Fiber core diameter |

50μm |

| Operating mode |

Continuous/adjustable |

| Lifetime for laser |

>100,000 hours |

| Cooling method |

Water cooling |

| Targeting |

Red light indication and CCD observation system |

| Power required |

AC 220/380V 50Hz |

| Average power consumption |

4.6kW |

| Remark:

1. The reference laser is Max photonics laser, the water tank is the special domain water tank, and the machine tool is the standard platform laser automatic welding machine; 2. The parameters in this table are for reference only, and the actual delivery equipment shall prevail. |

|

Core Features

1. The machine comes in comfy position to operate and only takes few steps to complete the installing process, which is same as regards to software learning and operation.

2. The machine is processing at a relatively high speed and precision rate during welding, which greatly result in its efficiency of welding.

3. The workpiece is extremely unlikely to be deformed from welding due to a limited area of heat affected zone.

4. The machine works at a structural and aesthetic welding seam in consistent width and depth, which save time to grind and polish it afterward.

5. The energy consumption of fiber laser is relatively low, where its photoelectric conversion rate is more than 35%.

6. The optical devices last in a long-life time and are basically maintenance-free for general use.

7. The machine is equipped with self-configured cooling system, circulating water to transfer heat away in the interior of fiber laser, no water supply required from the exterior.

8. The welding platform caters for mounting any types of jigs and fixtures if required.

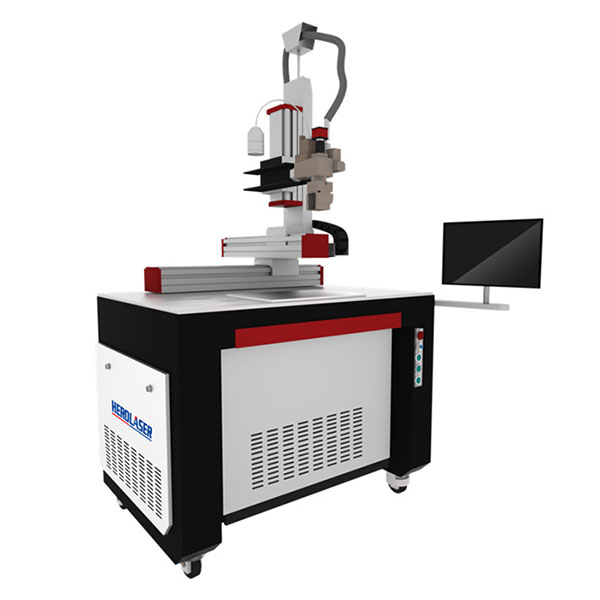

High efficiency, 10 times faster

Multi-language display panel operation, easy to understand, no experience, free training, easy to master

Strong performance and good quality

The machine is firm and durable, with good quality, and can adapt to the welding of different materials and various angles and lengths

Visual operation interface

With smart display, the display is more comprehensive and clear at a glance, and the operation is more simple and convenient

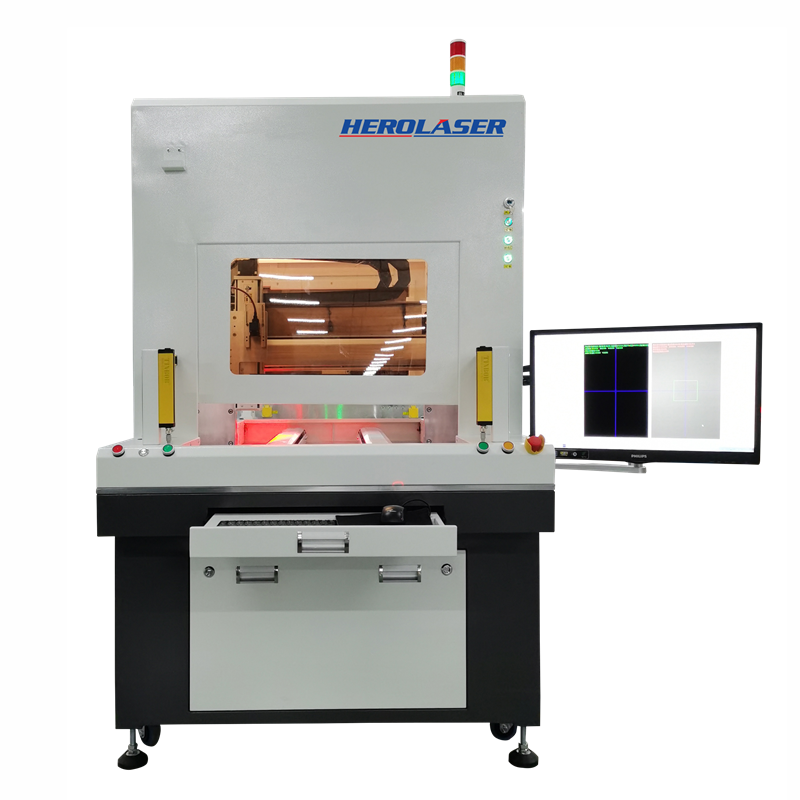

Sample Display