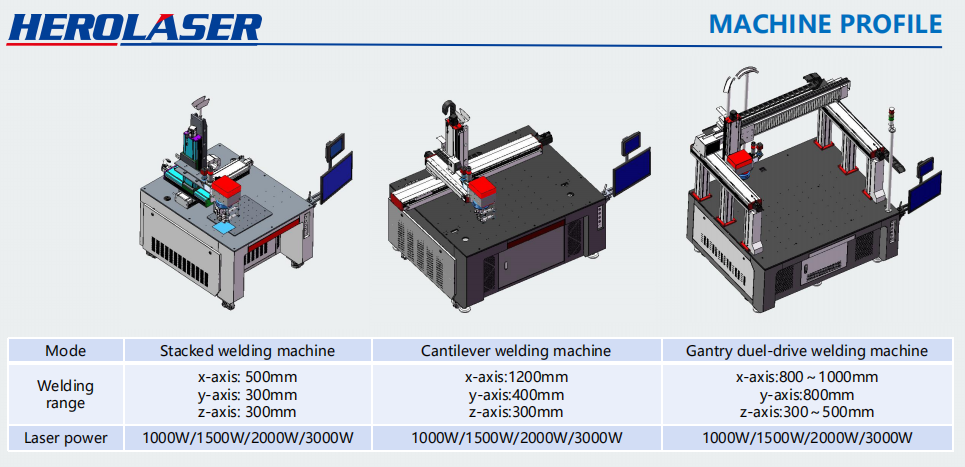

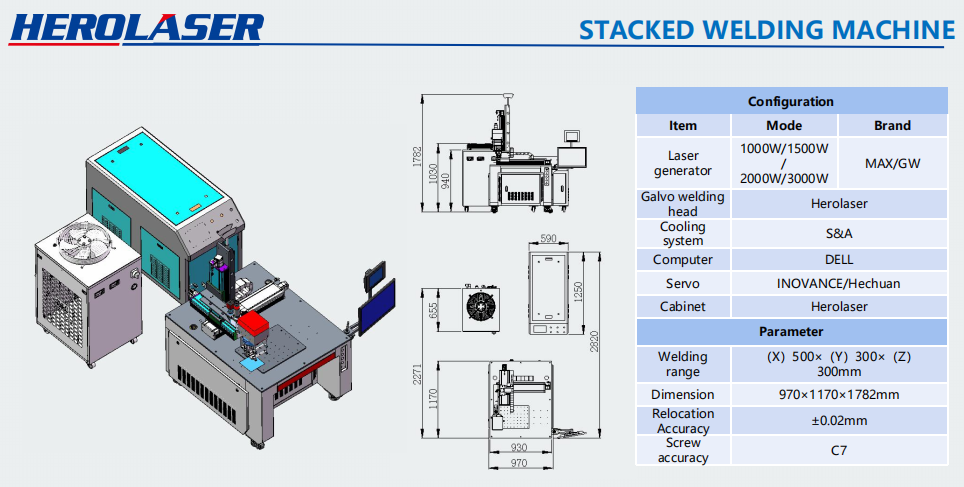

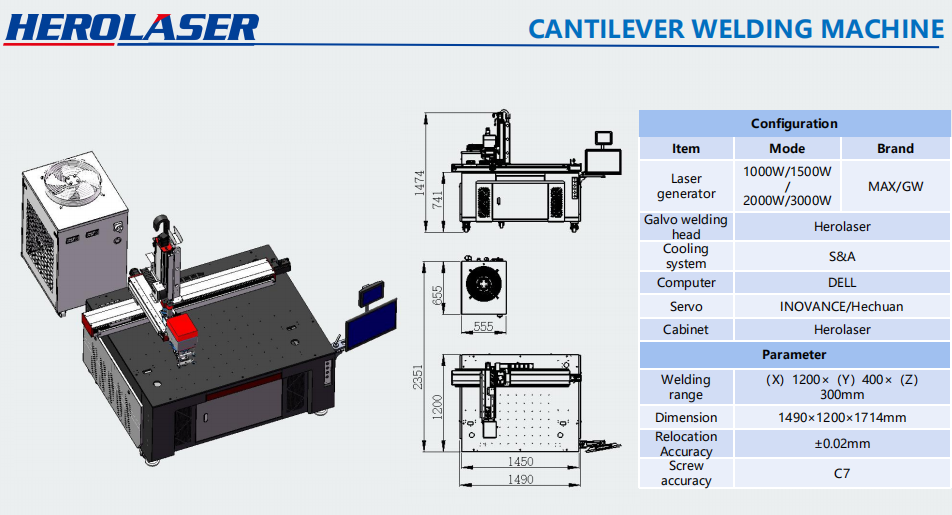

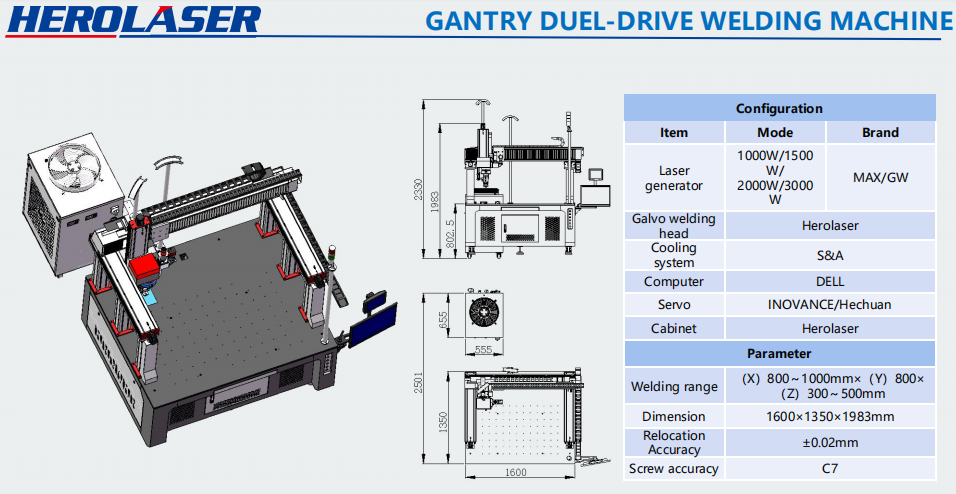

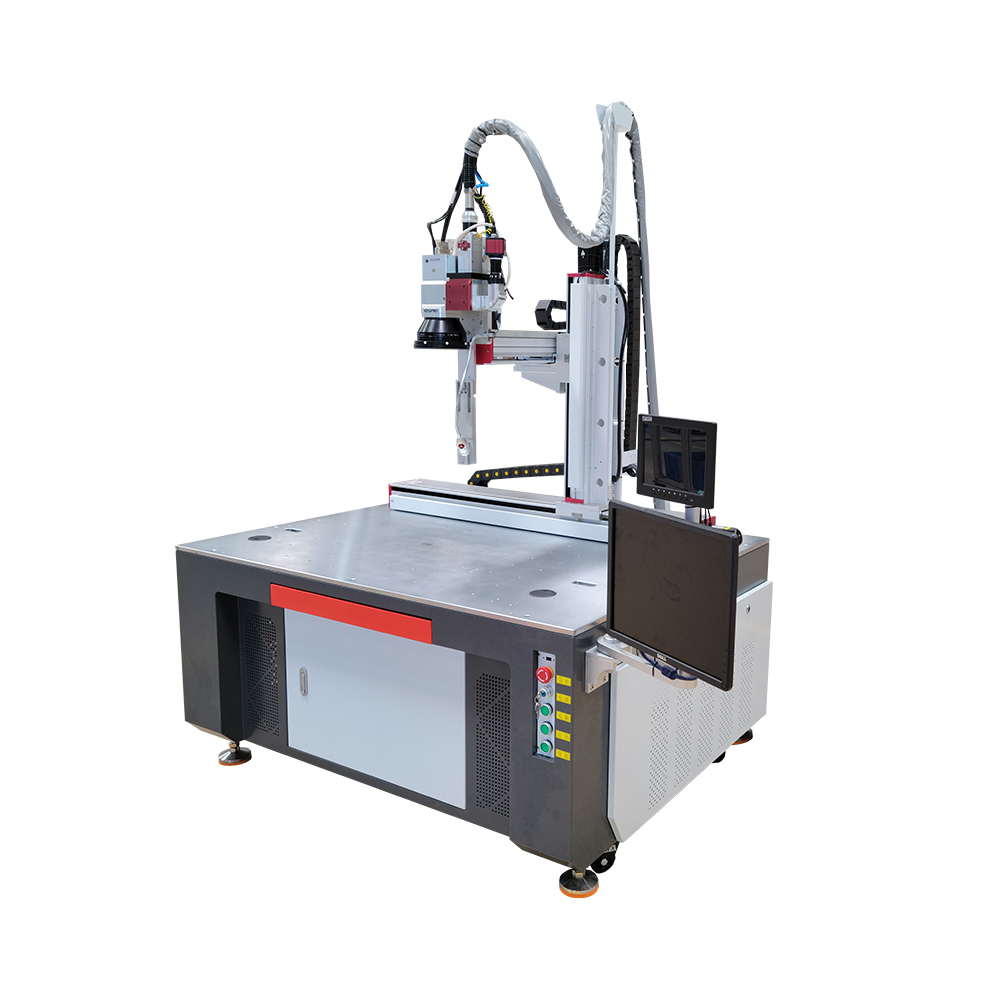

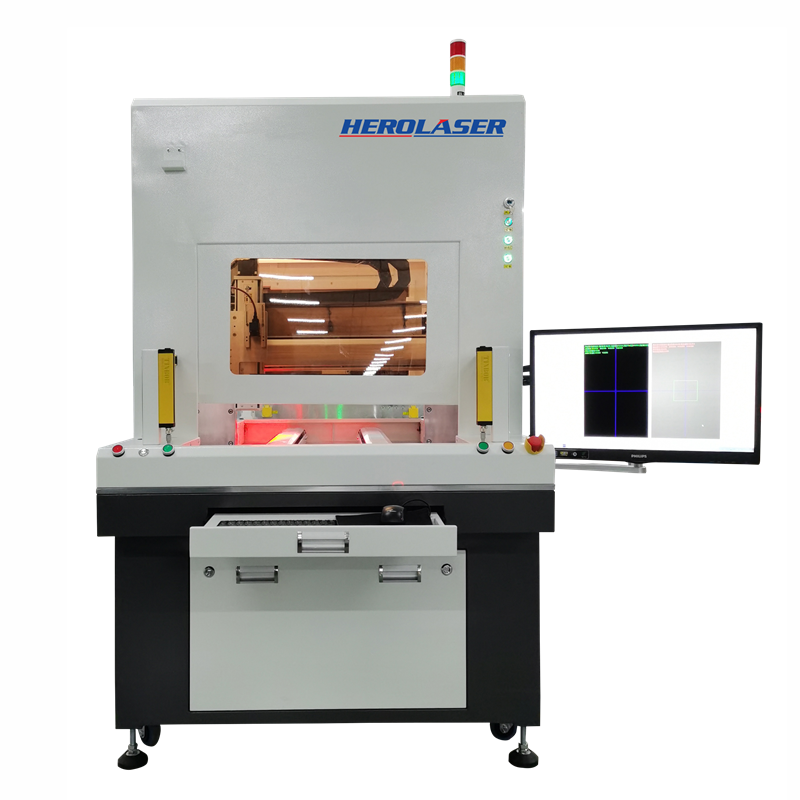

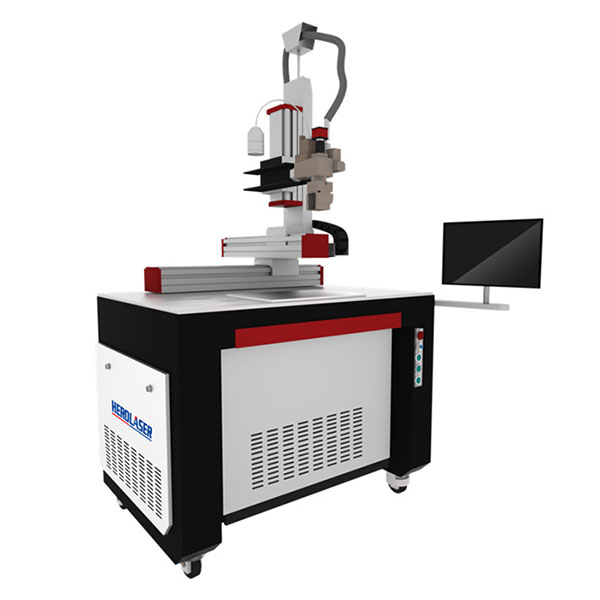

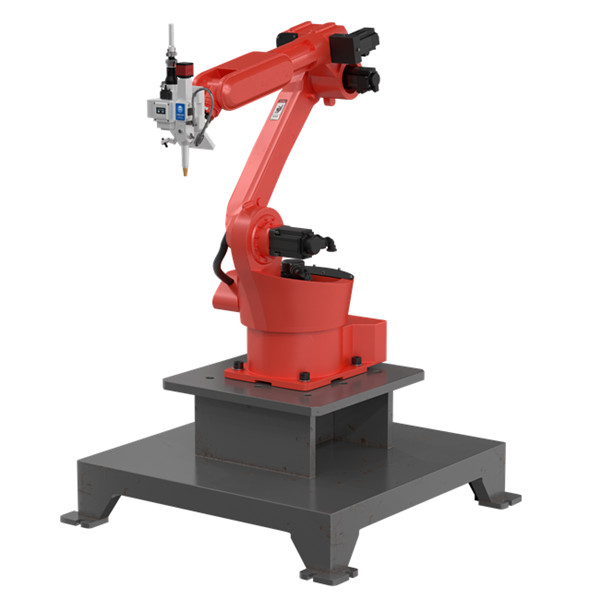

New energy battery laser welding machine

Product Introduction

Application

FPC is a flexible circuit board, which is a printed circuit board made of a flexible copper clad laminate as the base material. It is the key electronic interconnection of electronic products. It plays the role of conduction and transmission, and has high wiring assembly density. , good bending, lightweight, flexible process and other characteristics.

Material: Nickel, nickel-plated copper, etc.

Advantages :

1) The heat can be concentrated in a small area, and the heat-affected area is small;

2) Non-contact welding, no mechanical stress damage

Application

The battery connection pieces are generally rectangular, trapezoidal, triangular and stage-shaped. It can be used as a device that transmits current to prevent parts that should not be soldered from being connected by solder

Materials: Nickel Plated Cold Rolled Steel Sheet

Advantages:

1) The heat can be concentrated in a small area, and the heat-affected area is small;

2) Deep penetration with no-contact welding to meet strength and conductivity requirements

PRINCINPLE

Action flow:

① Manual upload battery

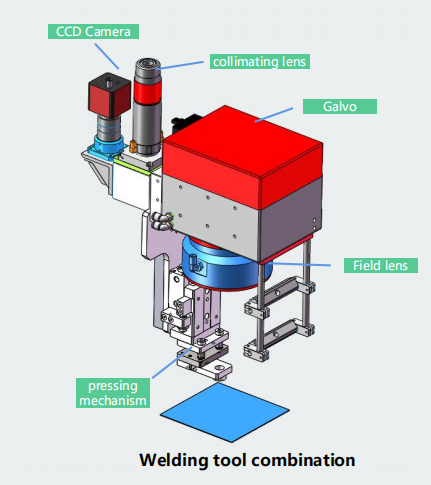

② The servo mechanism moves the welding head to the welding position, and the cylinder of the pressing mechanism moves downward to press the connecting piece (or FPC)

③ The laser welds the connecting piece (or FPC) through the welding head with the protective gas which will

protect the field lens and quickly cool the welding position.

PRINCINPLE