High Power 12KW Laser Welding Machine

Product Introduction

Welding technology is a key technology in ship manufacturing and the development of shipbuilding industry. Welding working hours account for about 30%-40% of the total working hours for shipbuilding. The welding cost accounts for 30%-50% of the entire hull cost, Welding efficiency and welding quality will directly affect the production cycle, cost, and hull quality of ship manufacturing. The traditional welding process welding steel plate needs to be grooved and filled with solder to meet the welding requirements. The thicker the plate, the greater the bevel angle, it requires multiple processes to be fully welded. will be high solder cost,Long welding time ,Poor weld flatness and poor firmness for This process

The traditional process of beveling requires at least 5 processes such as plasma cutting, grinding, drilling, milling, and beveling. Transfer 4 times, 4-5 workers (positions) can be completed, it is time-consuming and inconsistent accuracy,Using a 10,000-watt welding machine, only need one person, no need to transfer, and high accuracy. It can be completed in one-third of the time of traditional craftsmanship, improve the quality and efficiency of manufacturing.

Core Features

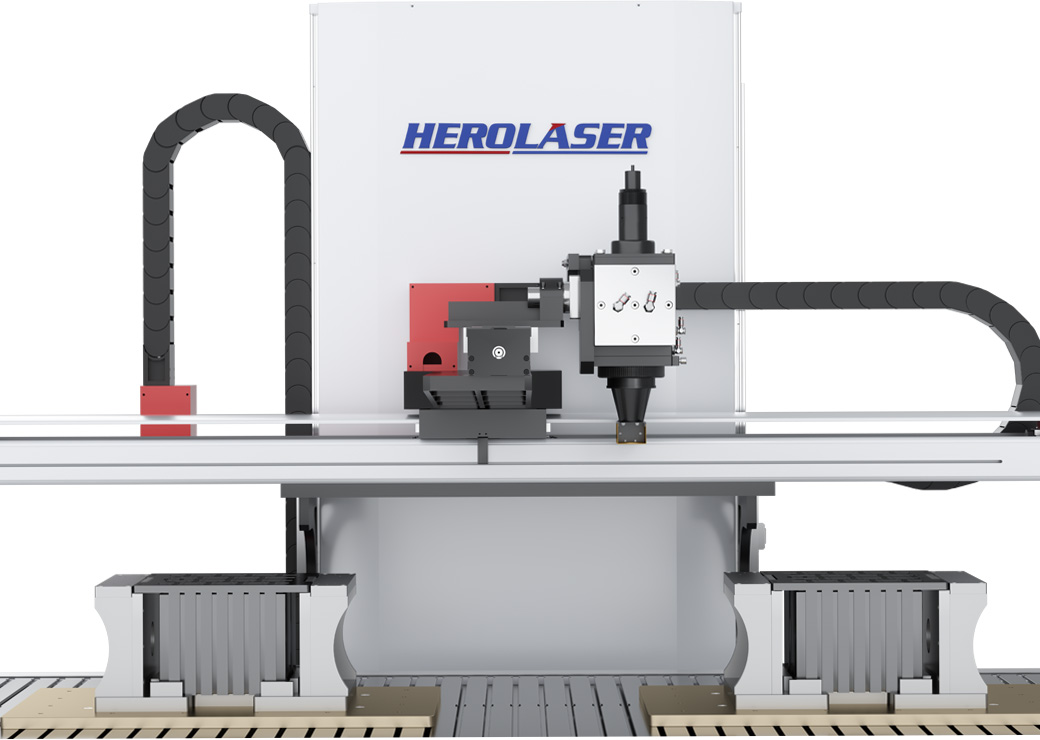

1. Steel plates below 20mm can be welded without beveling

2. Steel plates above 20mm only need to open a quarter of the traditional groove angle, The groove gap is greatly compressed, and the solder cost is smaller.

3. The efficiency can be increased by 6-10 times, achieve the improvement of production efficiency and manufacturing accuracy and good Firmness

4. The 12000W laser welding machine has excellent processing effects in butt welds and long fillet welds

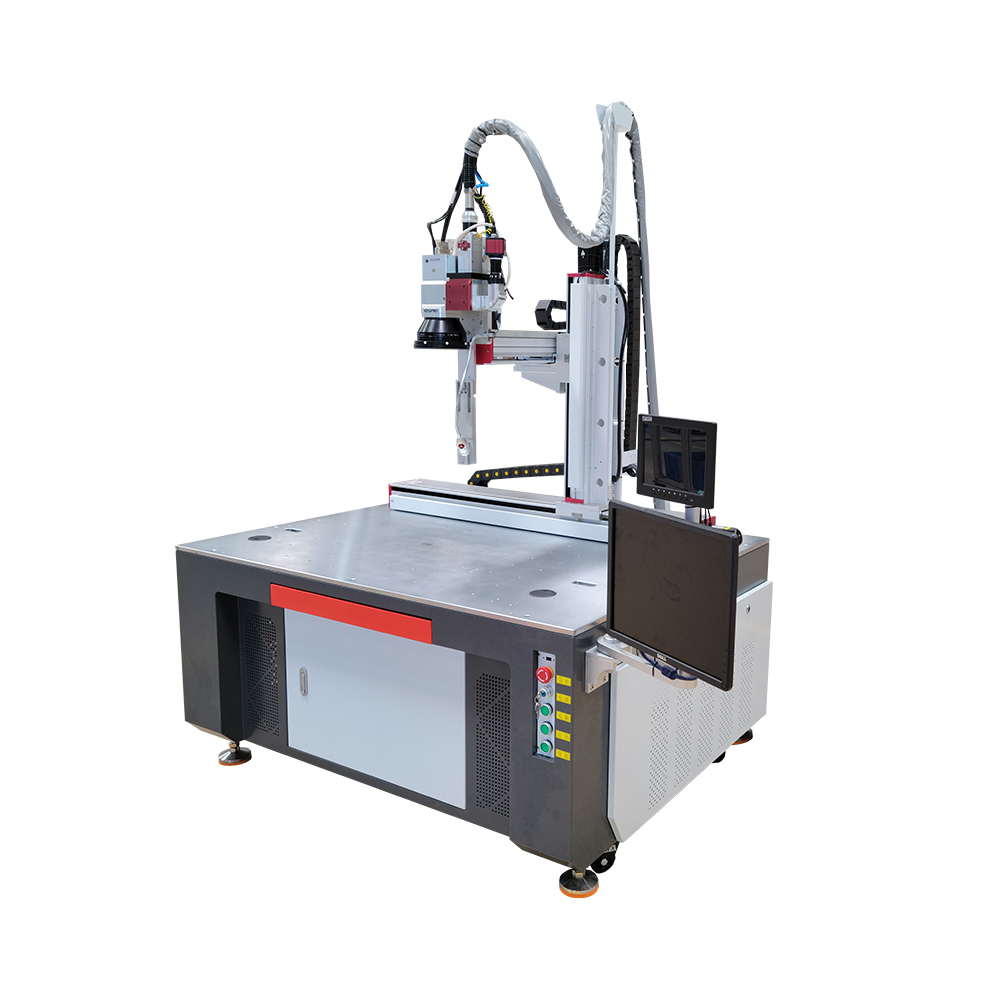

High efficiency, 10 times faster

Chinese display panel operation, easy to understand, no experience, free training, easy to master

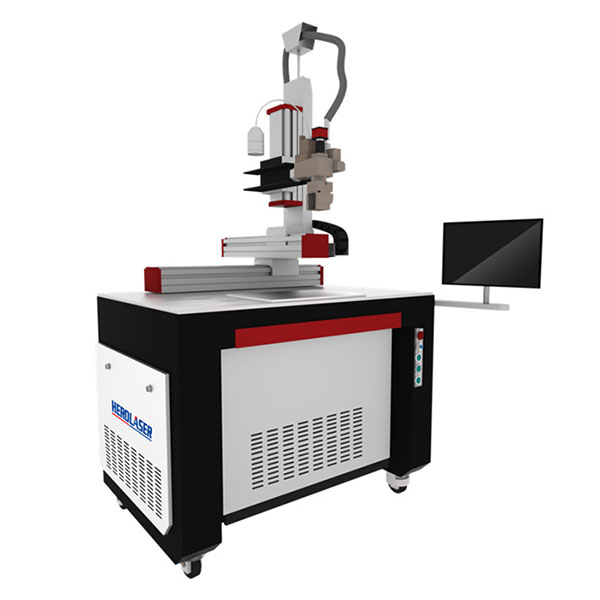

Strong performance and good quality

The machine is firm and durable, with good quality, and can adapt to the welding of different materials and various angles and lengths

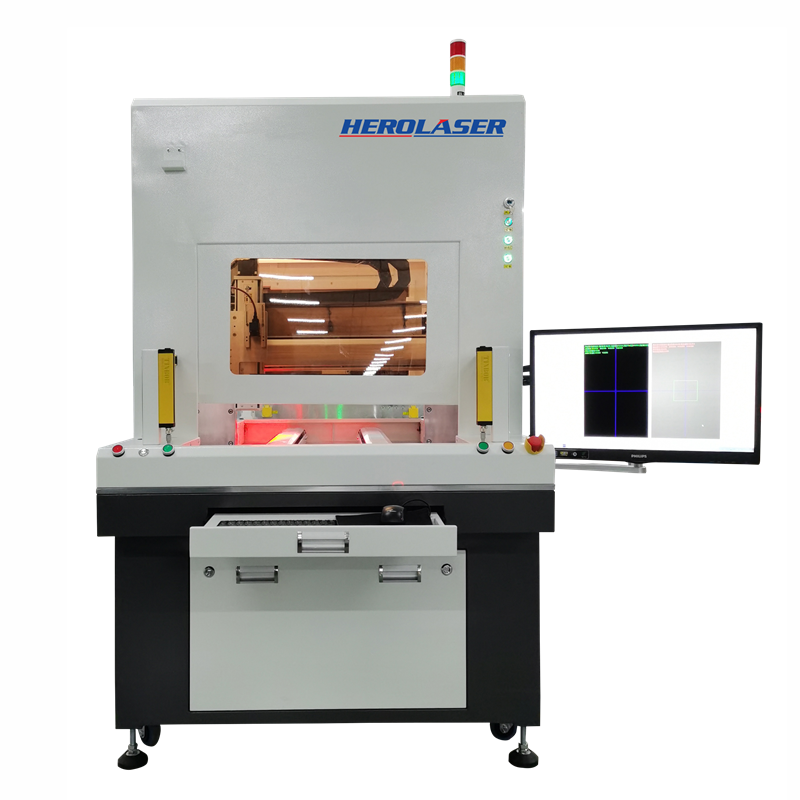

Visual operation interface

With smart display, the display is more comprehensive and clear at a glance, and the operation is more simple and convenient

Application Scenarios

Ship processing and manufacturing

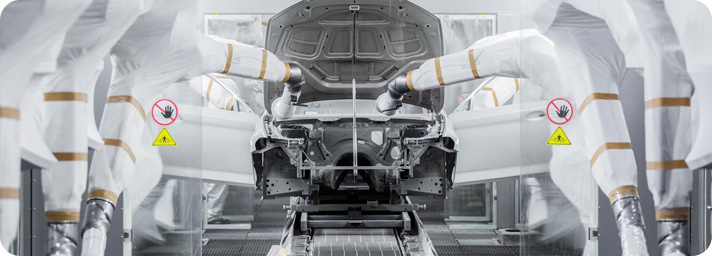

Vehicle manufacturing

Aerospace Industry

Pipeline welding industry

Wind power energy industry

And other industries in need

Videos and News for this product

Laser Welding Machine

on Apr 21,2022

Laser Welding Machine

on Apr 21,2022

Laser Welding Machine

on Apr 21,2022