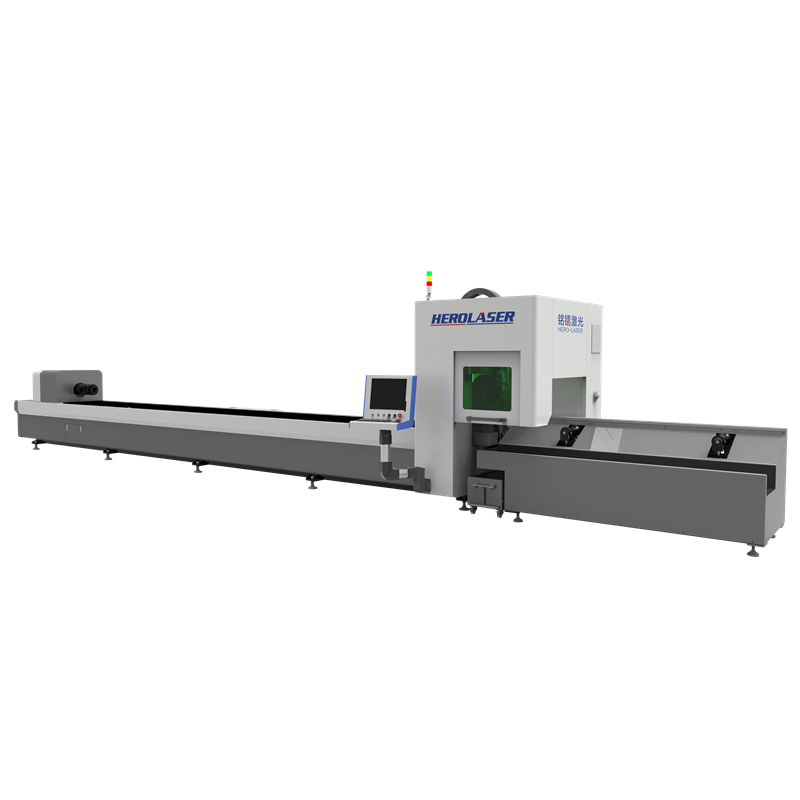

Tube Laser Cutting Machine (6016 Series )

Product Introduction

Technical Parameters

| THE PROJECT NAME | AND THE NUMBER |

| Equipment model | ML-CP-6016DQ-GS |

| Laser output power | 1.5KW |

| Chuck clamping range | Φ20mm~Φ160mm、□20~□110 |

| Maximum single tube weight | 60KG |

| Feeding length | ≤6300mm(Automatic feeding) |

| The length of the blanking | ≤2500mm(Customizable length) |

| Cutting thickness (related to laser power) |

Carbon steel≤6mm; Stainless steel≤4mm; Aluminum alloy≤3mm; Brass≤2mm; |

| Positioning accuracy | ≤±0.05mm |

| Repeatable positioning accuracy | ≤±0.03mm |

| Maximum X-axis velocity | ≤150m/min |

| Maximum Y-axis velocity | ≤120m/min |

| Maximum z-axis velocity | ≤65m/min |

| B axis maximum velocity | ≤150RPM |

| Acceleration of spaceflight | 1.2G |

| Demand for electricity | AC380V±5%/50Hz |

| The machine power consumption | 6KW-25KW |

| Cabinet Dimensions | 11000*2500*2300(mm) |

| Machine weight | ≈ 6000KG |

| Support for graphic formats | IGS/SAT/JHB |

Core Features

1. The tailing material can reach 0-60mm;

2. Very low operation and maintenance costs;

3. The laser cutting head will not contact the surface of the material and will not scratch the workpiece;

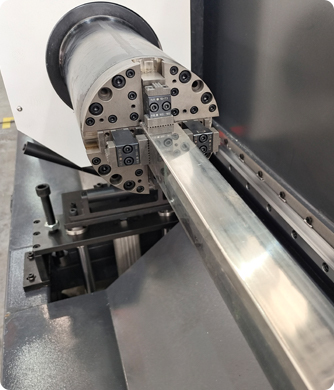

4. The front chuck clamps the full stroke without changing the jaws;

5. High-speed air travel, large acceleration, fast cutting response, and corners are not easy to burn;

6. Air blowing at the tail of the rear card, the pipe wall is clean, and the cutting dust and smoke are less;

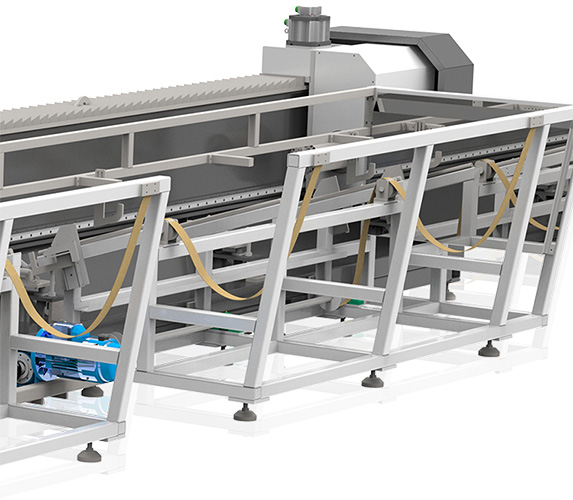

7. The height of the feeding fixed support wheel can be adjusted manually, and the feeding slope slides down combination;

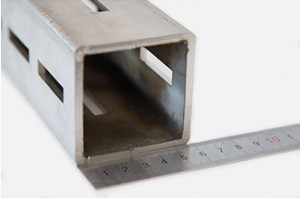

8. High-speed and high-quality laser cutting can be performed on profiles such as round tubes, square tubes, rectangular tubes, and waist round tubes;

9. The cutting section of the pipe is smooth without burrs, no slag, no blackening, no yellowing, and can easily realize the cutting of various complex graphics.

Automatic fast feeding

Body structure of pipe cutting machine optimized for fast automatic feeding

The distance between the waiting position and the processing position is very short, which is more than 90% faster than the automatic feeding speed of peers

The cutting surface is clean and free from defects

The pipe cutting section shall be smooth without burr, slag, blackening and yellow; It will not contact with the material surface and scratch the workpiece. It can easily realize the blowing at the tail of the card after cutting various complex graphics. The pipe wall is clean and the cutting dust and smoke are less

Ability of professional pipe cutting

The front chuck holds the full stroke without changing the claw. The rear chuck is blown at the tail, the pipe wall is clean, the cutting dust and smoke are less, the empty stroke is high-speed, the acceleration is large, the cutting response is fast, and the corner is not easy to burn

Actual picture of laser pipe cutting machine

Application Scenarios

The feeding is fixed, the height of the supporting wheel can be adjusted manually, and the blanking slope is combined with sliding; It can perform high-speed and high-quality laser cutting on round tube, square tube, rectangular tube, waist tube and other profiles

Videos and News for this product

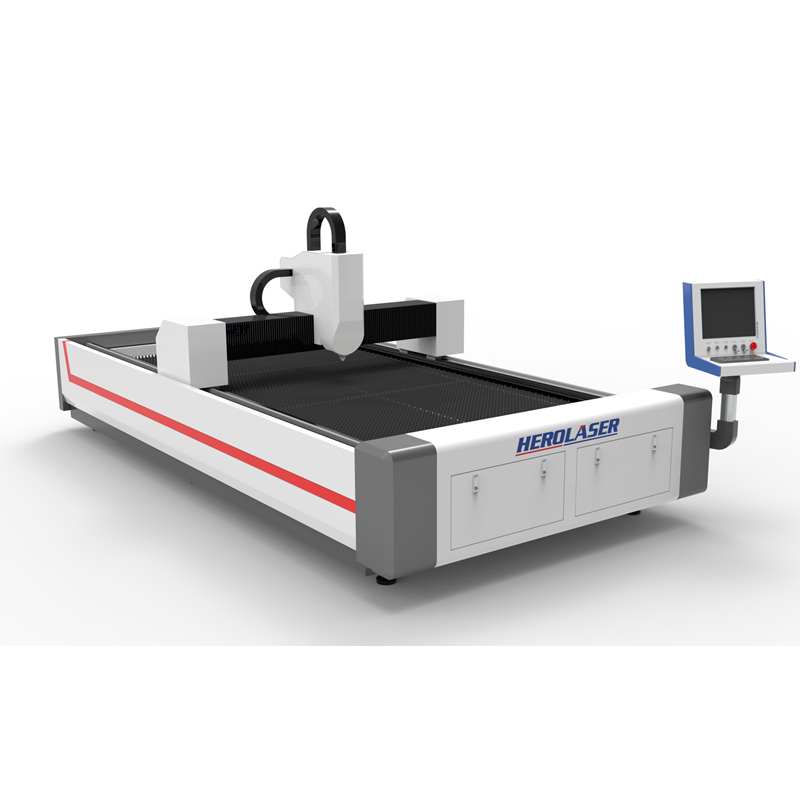

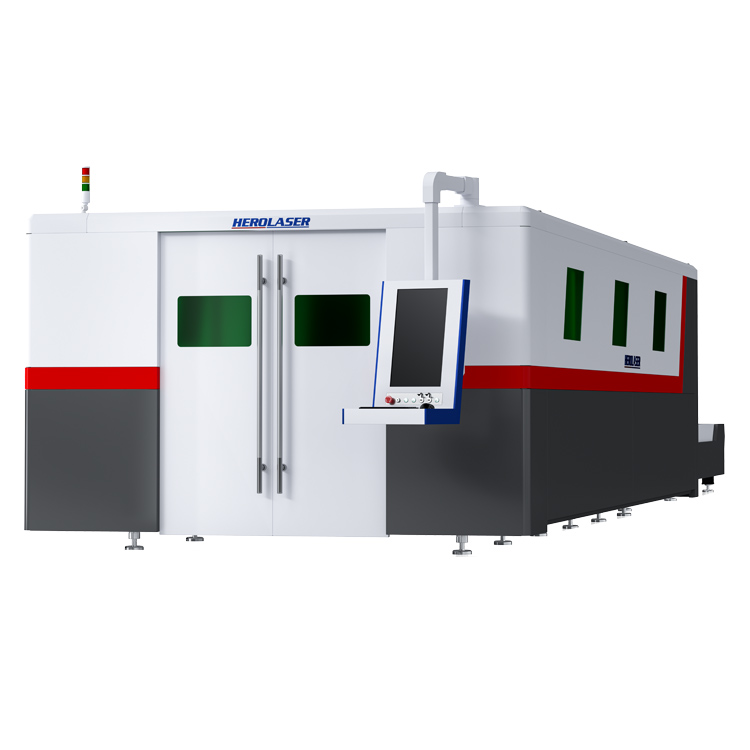

Fiber Laser Cutting Machine

on Apr 21,2022

Fiber Laser Cutting Machine

on Apr 21,2022

Laser Cutting Machine

on Apr 21,2022