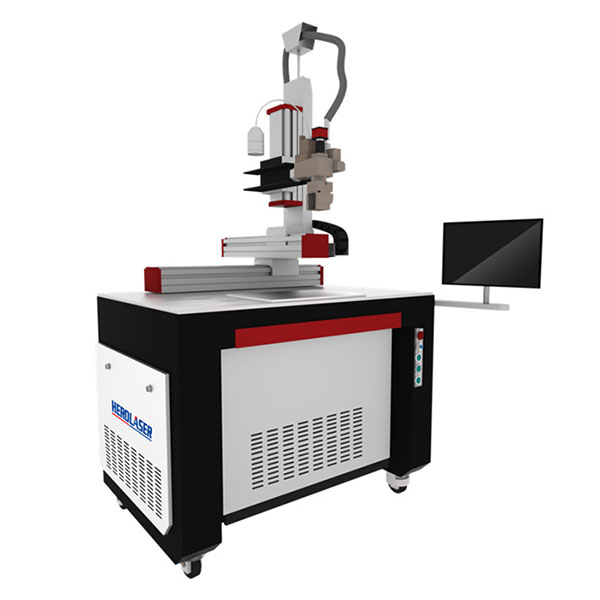

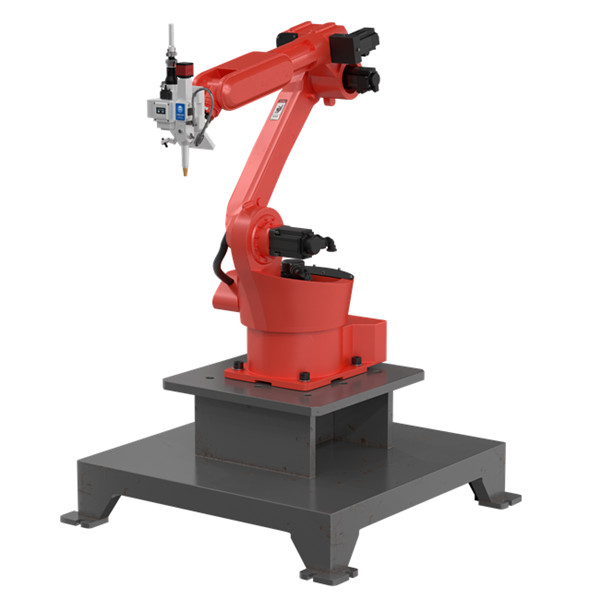

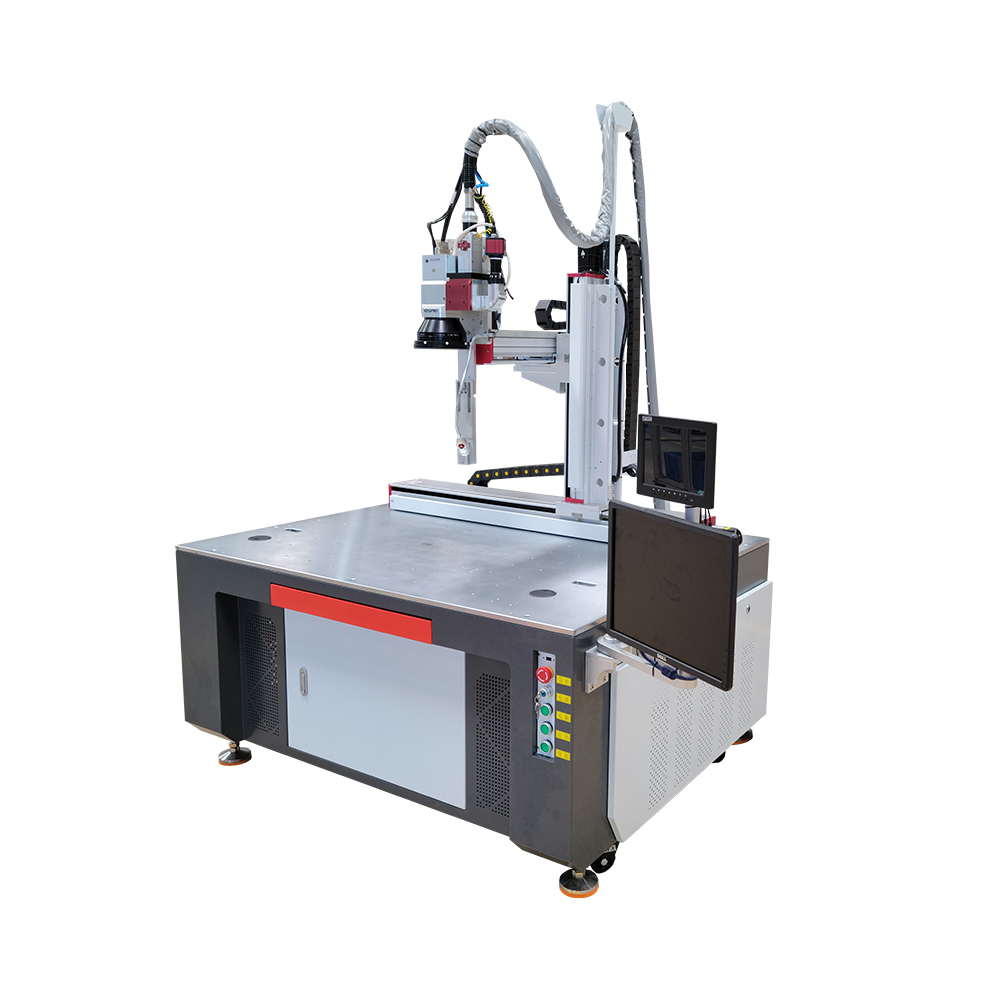

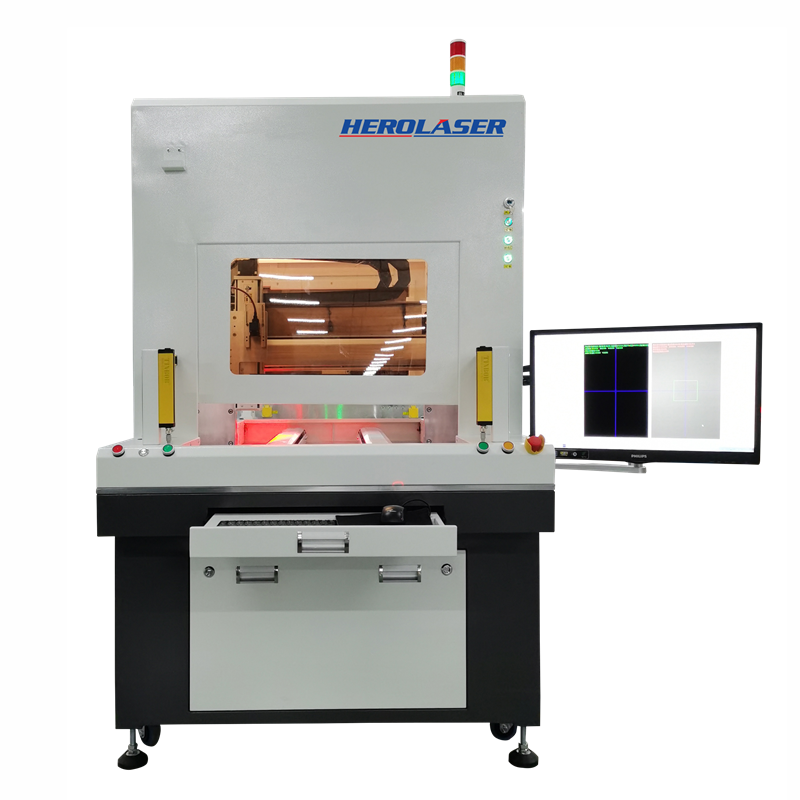

3/4/6 Axis Automatic Laser Welding Machine

Product Introduction

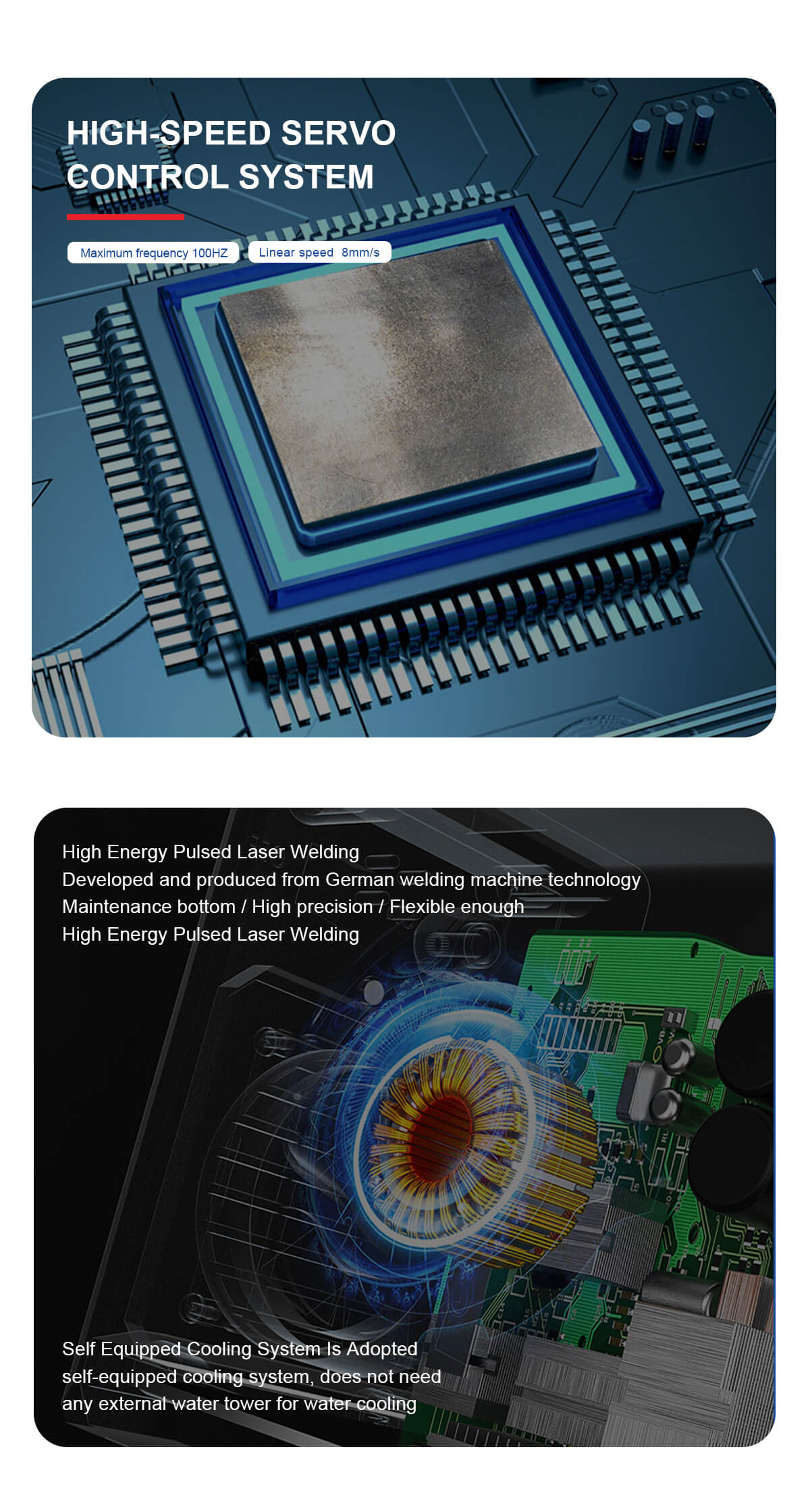

Herolaser automatic laser welding machine can realize the welding of metal work pieces in straight lines, circles and other arbitrary trajectories, such as phone housing, mobile phone batteries, sensors, medical equipment and other industries. Laser welding machines use high-energy pulsed lasers to weld objects, laser pulses’ high energy and high density can make the welding smooth, the weld width is small and the heat-affected zone is small, and it can complete the precision welding that cannot be achieved by the traditional technology. Laser automatic welding machine series welding machine is a laser welding machine developed and produced with German welding machine technology.

Core Features

1. Excellent beam quality: Adopt Germany IPG, and other reliable advanced fiber laser source, beam quality is much better than traditional solid-state laser, focused spot diameter less than 20um, divergence angle is 1/4 of diode-pumped laser. Especially suitable for precise and excellent marking.

2. Low cost: The highest electrical/ optical conversion rate is up to 30%, the whole power consumption is less than 500W, this is 1/10 of lamp-pumped solid-state laser marking machine, save much of energy cost.

3. Maintenance-free: laser source no need of any maintenance, also no need adjust or clean the lens.

4. Long term service life of the laser source: fiber laser marking machine uses a laser diode as the pump source, the average service time can up to 100,000 hours.

5. High marking speed: The marking speed is over 3 times of first and second generation of laser markers.

Application Scenarios

Digital mobile phone battery industry

Mobile phone shell industry

Transportation industry

Medical equipment industry

And other industries in need

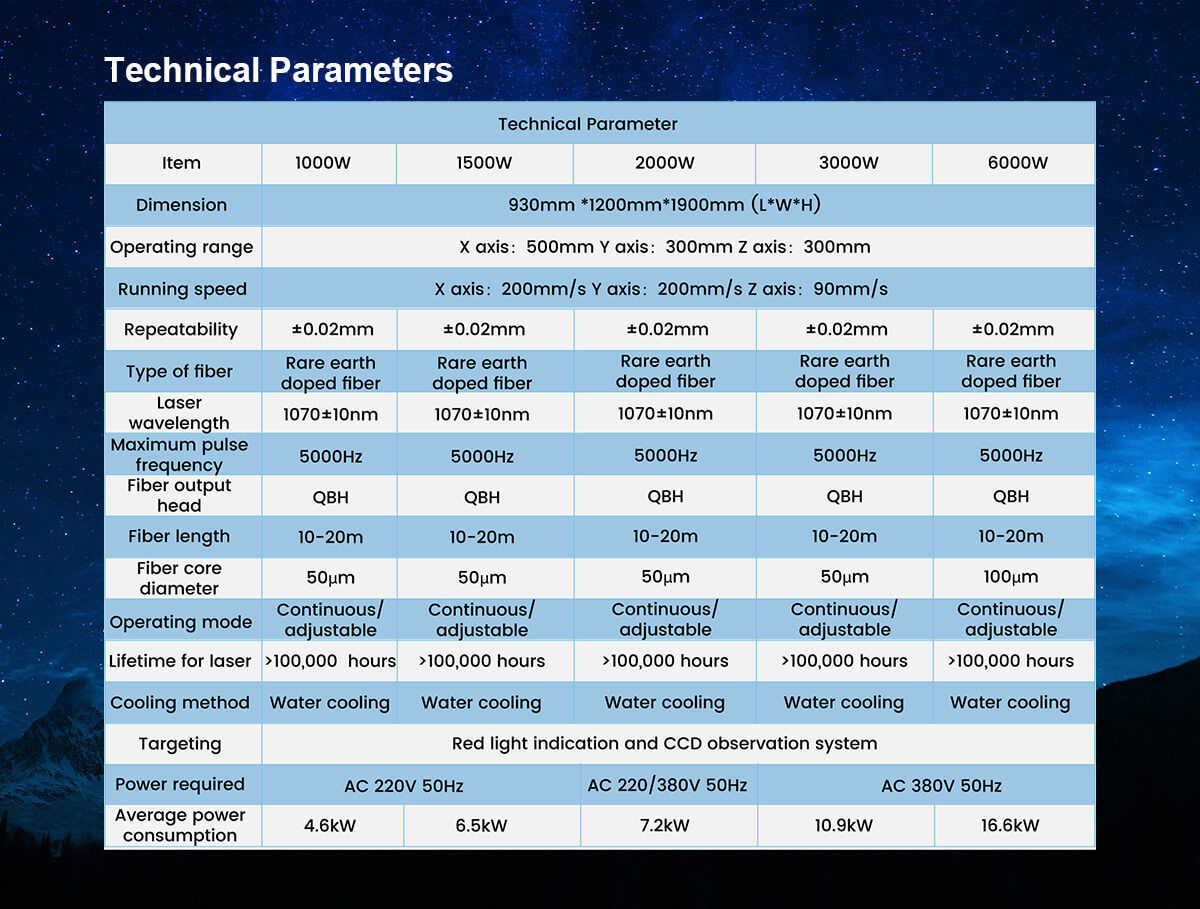

| Parameters of 3D platform laser automatic welder | |||||||

| NO. | Main Parts Description | Small platform | |||||

| 1000w | 1500w | 2000w | 3000w | 4000w | 6000w | ||

| 1 | Overall size | 930mm*1200*1900mm | |||||

| 2 | Weight | 250kg | 250kg | 250kg | 250kg | 280kg | 300kg |

| 3 | Electricity demand | 220V±10%, 50Hz | 220V±10%, 50Hz | 220/380V±10%, 50Hz | 220/380V±10%, 50Hz | 220/380V±10%, 50Hz | 380V±10%, 50Hz |

| 4 | Effective travel of module | X axis:500mm | |||||

| Y axis:300mm | |||||||

| Z axis:300mm | |||||||

| 5 | Running speed of module | X axis:10m/min | |||||

| Y axis:10m/min | |||||||

| Z axis:5m/min | |||||||

| 6 | Repeated positioning accuracy | ±0.02mm | |||||

| 7 | Wavelength | 1070nm | |||||

| 8 | Fiber core radium | 50μm | 50μm | 50μm | 50μm | 50/100μm | 100μm |

| 9 | Fiber length | 10-20m | |||||

| 10 | Cooling method | Circulating water cooling | |||||

| 11 | Working mode | Continuous /pulse |

|||||

| 12 | Maximum pulse frequency | 5000Hz | |||||

| 13 | Laser working lifetime | > 100,000 hours | |||||

| 14 | Position model | Red light indicator, CCD observation system | |||||

| 15 | Current Consumption | 4.58KW | 6.47KW | 7.24KW | 10.86KW | 13.68KW | 16.63KW |

| Parameters of 3D platform laser automatic welder | |||||||

| NO. | Main Parts Description | Large platform | |||||

| 1000w | 1500w | 2000w | 3000w | 4000w | 6000w | ||

| 1 | Overall size | 1550×1200×2000mm | |||||

| 2 | Weight | 250kg | 250kg | 250kg | 250kg | 260kg | 350kg |

| 3 | Electricity demand | 220V±10%, 50Hz | 220V±10%, 50Hz | 220/380V±10%, 50Hz | 220/380V±10%, 50Hz | 220/380V±10%, 50Hz | 380V±10%, 50Hz |

| 4 | Effective travel of module | X axis:1000mm | |||||

| Y axis:600mm | |||||||

| Z axis:500mm | |||||||

| 5 | Running speed of module | X axis:10m/min | |||||

| Y axis:10m/min | |||||||

| Z axis:5m/min | |||||||

| 6 | Repeated positioning accuracy | ±0.02mm | |||||

| 7 | Wavelength | 1070nm | |||||

| 8 | Fiber core radium | 50μm | 50μm | 50μm | 50μm | 50/100μm | 100μm |

| 9 | Fiber length | 10-20m | |||||

| 10 | Cooling method | Circulating water cooling | |||||

| 11 | Working mode | Continuous /pulse |

|||||

| 12 | Maximum pulse frequency | 5000Hz | |||||

| 13 | Laser working lifetime | > 100,000 hours | |||||

| 14 | Position model | Red light indicator, CCD observation system | |||||

| 15 | Current Consumption | 4.58KW | 6.47KW | 7.24KW | 10.86KW | 13.68KW | 16.63KW |

Configuration Parameter

|

S/N |

Name |

Specifications & Models |

QTY |

Brand |

Remark |

|

01 |

Fixture mounting plate |

350mm×450mm |

1 |

Hero Laser Custom |

|

|

02 |

Laser |

According to sample welding requirements |

1 |

MAX or IPG |

|

|

03 |

Motor |

servo motor |

3 |

Huichuan |

|

|

04 |

Computer |

PC/Industrial Computer |

1 |

Advantech |

|

|

05 |

Chiller |

According to laser power |

1 |

S & A |

|

|

06 |

Welding head |

According to sample welding requirements |

1 |

Hero Laser |

|

|

07 |

CCD Visual observation system |

camera |

1 |

Microsan |

|

|

light source |

Basler/LeTV Light Source |

||||

|

08 |

Z axis module |

300mm stroke |

1 |

Hero Laser Custom |

X, Y axis screw lead 10mm, Z axis screw lead 5mm; screw accuracy: C7 |

|

09 |

X axis module |

500mm stroke |

1 |

Hero Laser Custom |

|

|

10 |

Y axis module |

300mm stroke |

1 |

Hero Laser Custom |

|

|

11 |

Rotating table | Three-jaw rotary chuck | 1 | Hero Laser Custom | |

|

12 |

Lower cabinet | Sheet metal welding, paint baking | 1 | Hero Laser Custom |

HEROLASER Intelligent Laser Processing Equipment Product Catalog

For bulk purchases or customized products, please contact online customer service, or leave a message.

You can also send email to sales@herolaser.net.