Integrated double head laser cleaning machine

Product Introduction

The Integrated double head laser cleaning machine is a high-tech intelligent product of Herolaser's new generation of surface cleaning.

Fiber high-power laser dual-head cleaning machine can independently control a single cleaning head or dual-head cleaning at the same time.

The laser cleaning machine has preset modes such as rust removal, paint removal, and oil removal.

The intelligent laser cleaning machine can automatically focus and clean the surface.

It can remove resin, oil, stain, dirt, rust, coating, plating and paint on the surface of objects.

Core Features

1. Wide range of applications: It can remove resin, oil, stain, dirt, rust, coating, plating, paint on the surface of objects, and can protect the surface of brittle materials. The energy density is concentrated, and the highly reflective material can also be easily applied.

2. Auto-focus technology: non-contact 360° cleaning, parameter setting, auto-focus, cleaning with curved surfaces, high cleanliness of the cleaning surface, free from space and location restrictions.

3. Environmental protection and energy saving: The cleaning is stable and efficient, and the micron-scale pollution particles are effectively removed. The cost of laser cleaning is only 1/5 of the cost of chemical cleaning, which is more green and energy-saving.

4. Double-head high-efficiency cleaning: fiber high-power laser double-head cleaning machine can independently control a single cleaning head or dual-head cleaning at the same time;

5. Intelligent multi-language operating system: full touch screen operation interface, supports multi-language. A variety of parameters can be set by themselves, once set, and recalled at any time. Realize the control of the galvanometer of the laser.

6. General industrial design: The component shapes are scientifically calculated, the layout is reasonable, and the thermal load and mechanical load on the substrate during operation are small. Clear identification and easy maintenance.

7. Sturdy and durable: Tailor-made thickened sheet metal, solid structure, anti-deformation, good heat dissipation.

8. Customizable design, suitable for automated operations: Herolaser has conquered large-format, automated, high-precision collaborative motion technology.

Comparison with traditional clean methods

|

Comparision |

Laser Cleaning |

Chemical Cleaning |

Mechanical Grinding |

Dry ice cleaning |

|

Washiing Method |

non-contact cleaning |

contact cleaning |

Abrasive contact cleaning |

non-contact cleaning |

|

Harm to base material |

None |

Yes |

Yes |

None |

|

Washing Efficiency |

High |

Low |

Low |

Mid. |

|

Consumable |

Power |

Chemical Detergent |

Abrasive paper, grinder, abrasive stone |

Dry Ice |

|

Washing result |

Very good, very clear |

Medium, uneven |

Medium, uneven |

Good, uneven |

|

Precision Washing |

Accuracy controllable. High precision |

Uncontrollable, low precision. |

Uncontrollable, medium precision. |

Uncontrollable, poor precision. |

|

Safety/Environment |

No pollution |

Chemical pollution |

Dust pollution

|

No pollution |

|

Operation |

Easy to operate, portable or automation optional. |

Complicated process, higher technical requirement of the operator. Pollution prevention measures required. |

Need more time & manpower. Pollution prevention measures required. |

Easy to operate, portable or automatic. |

|

Investment |

High investment on machine. But no consumable, low maintenance cost |

Low investment on machine. But expensive consumables |

Medium investment on machine. High man-power cost. |

Medium investment on machine. High consumable cost. |

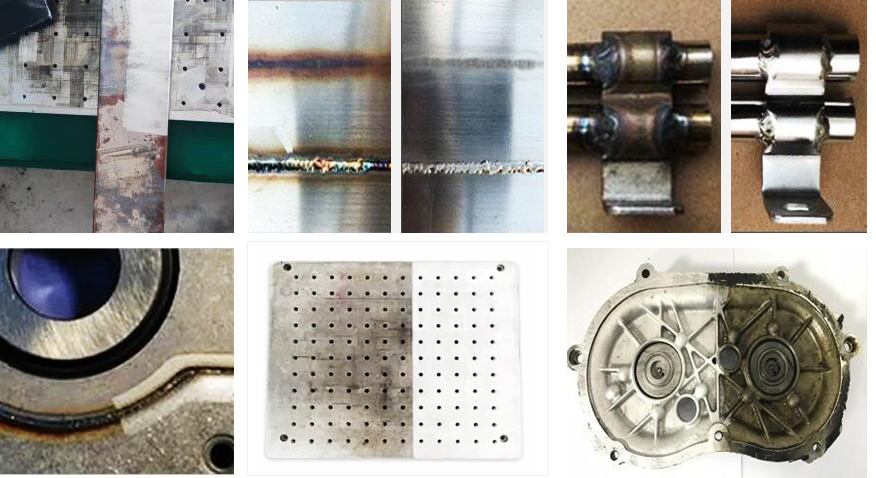

Sample Display

Application Scenarios

Suitable for cleaning welded surfaces of steel and aluminium,as a pre-treatment for welded surfaces, which is after welding.

Applications include the automotive industry, precision tool production, shipbuilding and other industries.

| Item |

Parameter |

Parameter |

| 1 | Laser type | Domestic (h) optical fiber laser /Import a (i) a pulsed laser |

| 2 | Laser wavelength | 1064 nm |

| 3 | cooling way | water-cooling |

| 4 | Optical fiber length | 3~15M(customizable) |

| 5 | laser power | 200~1000W |

| 6 | supply voltage | AC~220V |

| 7 | Power of the whole machine | 4.6~14kW |

| 8 | cabinet shape size | 1504*790*1496mm |

| 9 | whole machine weight | 410kg |

| 10 | cooling-water machine | Double temperature |

| 11 | Optional matching | Handheld (SC) / Automation (JX) |

| 12 | Handheld head weight | Standard model 1.4~2.3kg |

| 13 | working ambient temperature | 5 ~ 40 °C |

| 14 | approval standards | CE certification |

![]()

HEROLASER Intelligent Laser Processing Equipment Product Catalog

For bulk purchases or customized products, please contact online customer service, or leave a message.

You can also send email to sales@herolaser.net.