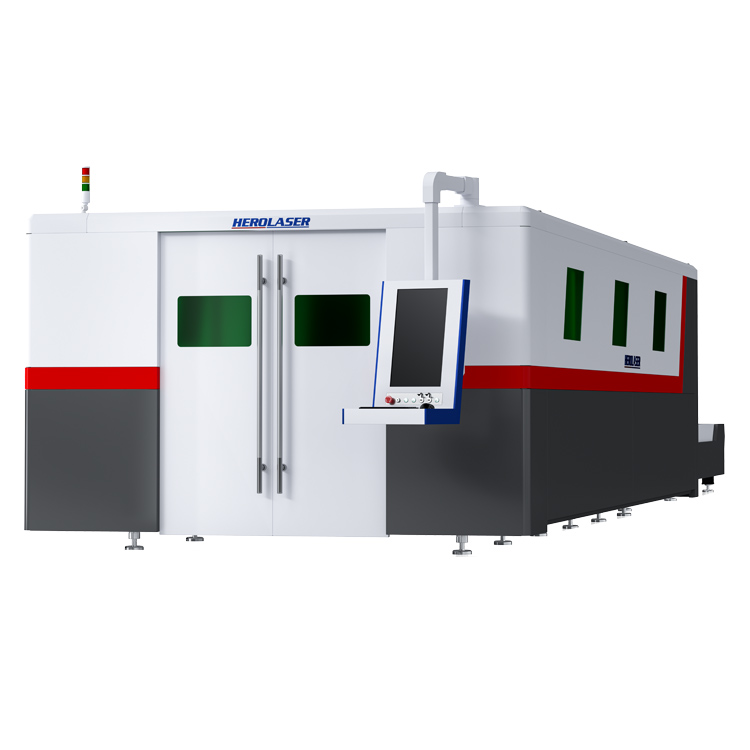

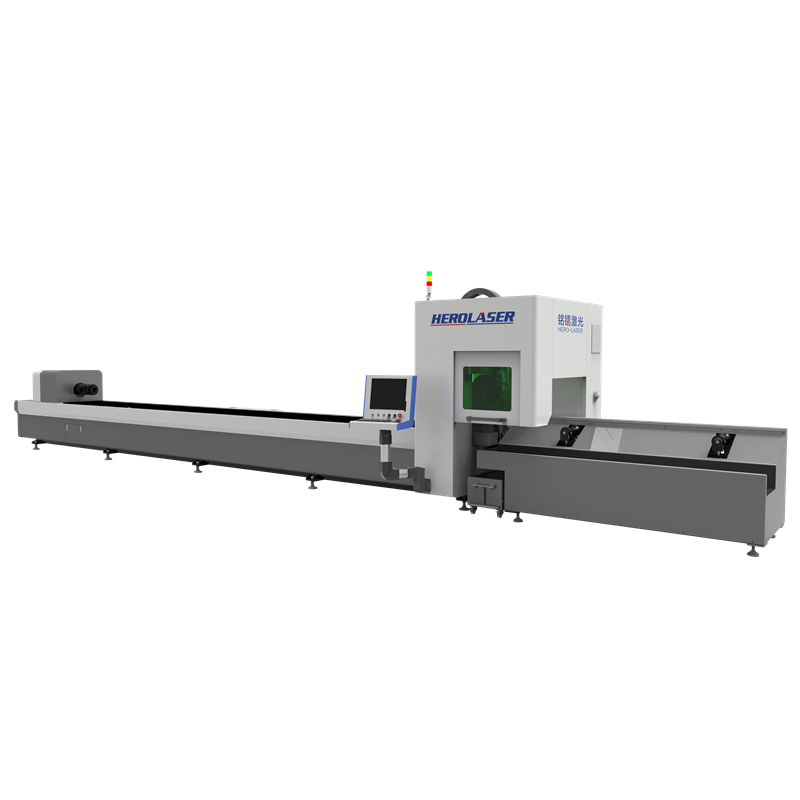

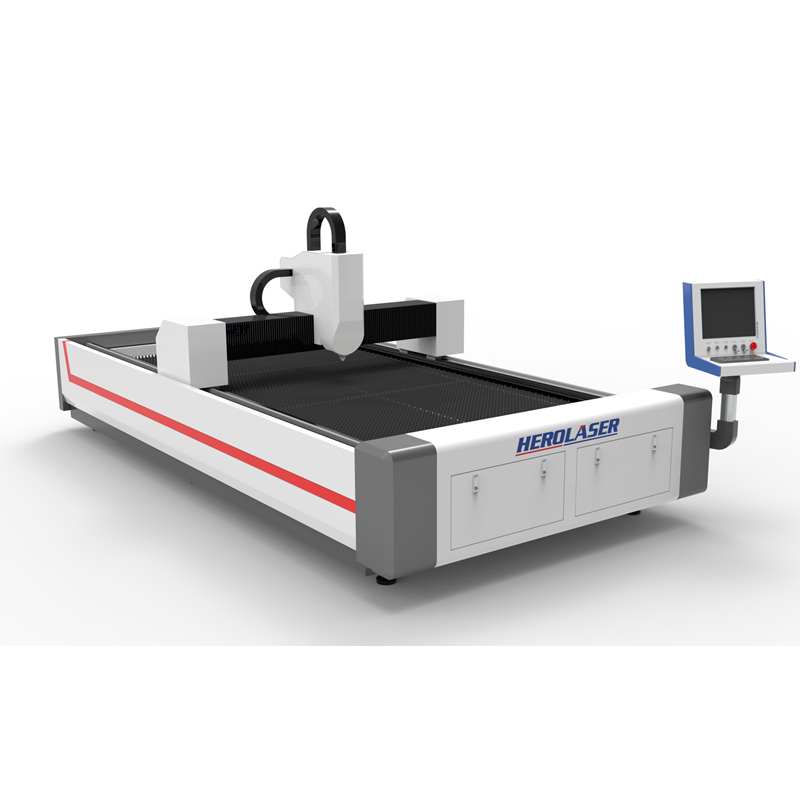

Small Size Precision Fiber Laser Cutting Machine

Product Introduction

Laser cutting uses a high-power density laser beam to quickly heat the material to vaporization temperature and evaporate to form a hole, move the beam to form a slit, so that realize the materials cutting . based on this ,Herolaser small area high precision cutting machine also achieves high-precision cutting, no tool wear, low heat impact, fast speed, automatic positioning, automatic correction and other functions.

Technical Parameters

|

Optical performance parameter |

|

|

Laser source wavelength |

ML-C6-QF |

|

Output power rate of the Laser source |

1070nm |

|

Effective cutting area |

600mm*600mm |

|

Cutting thickness (depend on Laser source power) |

Carbon ≤8mm;Stainless Steel ≤4mm; Aluminum Alloy ≤2mm; Copper ≤2mm; |

|

Positioning accuracy |

≤±0.03mm |

|

Repeated position accuracy |

≤±0.02mm |

|

Max speed of X-axis |

≤20m/min |

|

Max speed of Y-axis |

≤20m/min |

|

Max speed of Z-axis |

≤17m/min |

|

Synthesis speed |

≤20m/min |

|

Max accelerated speed |

0.3G |

|

Bearing weight |

300KG |

|

Electric demand |

AC220V±5%50Hz |

|

Total Power consumption |

6KW-25KW |

|

Dimension |

1880*1450*2100(mm) |

|

Machine weight |

About 1200KG |

|

Support Graphical format |

DXF |

Core Features

1. High Precision laser cutting machine

Stable, mature technology, high cutting efficiency, small footprint, flexible application with full-time cutting, high utilization of the materials, strong expandability , and very flexible

2. High-precision host

Precision linear guide, high precision positioning, less wear; can keep high precision for a long time, easy and interchangeable

3. Laser cutting head

The laser cutting head is equipped with a sensitive bus-type capacitor, which can be adjusted to the ideal focal length to ensure the cutting efficiency and cutting effect

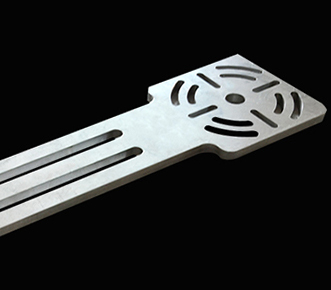

4. Precise cutting

Realize the precise cutting and nearly without error and the cutting surface is smooth and flat

Application Scenarios

|

Optical performance parameter |

|

|

Laser source wavelength |

ML-C6-QF |

|

Output power rate of the Laser source |

1070nm |

|

Effective cutting area |

600mm*600mm |

|

Cutting thickness (depend on Laser source power) |

Carbon ≤8mm;Stainless Steel ≤4mm; Aluminum Alloy ≤2mm; Copper ≤2mm; |

|

Positioning accuracy |

≤±0.03mm |

|

Repeated position accuracy |

≤±0.02mm |

|

Max speed of X-axis |

≤20m/min |

|

Max speed of Y-axis |

≤20m/min |

|

Max speed of Z-axis |

≤17m/min |

|

Synthesis speed |

≤20m/min |

|

Max accelerated speed |

0.3G |

|

Bearing weight |

300KG |

|

Electric demand |

AC220V±5%50Hz |

|

Total Power consumption |

6KW-25KW |

|

Dimension |

1880*1450*2100(mm) |

|

Machine weight |

About 1200KG |

|

Support Graphical format |

DXF |

HEROLASER Intelligent Laser Processing Equipment Product Catalog

For bulk purchases or customized products, please contact online customer service, or leave a message.

You can also send email to sales@herolaser.net.