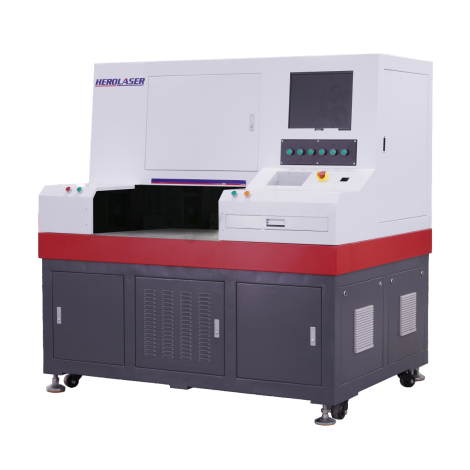

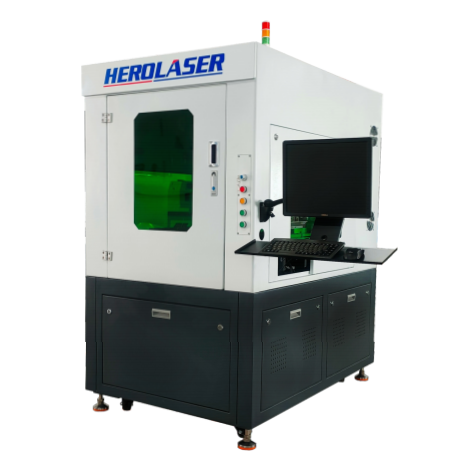

Portable Fiber Laser Marking Machine

Product Introduction

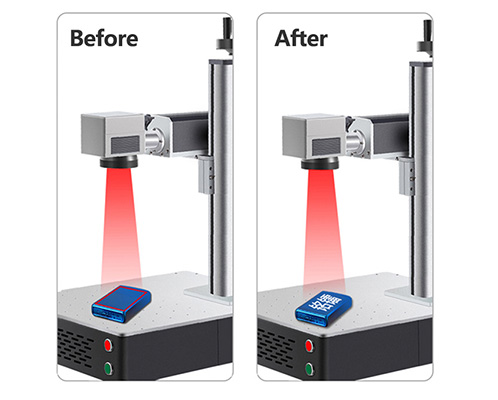

Integrated with mini marking system, the portable fiber laser marking machine is developed from typical fiber laser widely adopted over domestic and international market. The marking machine achieve its functions in which fiber laser is outputting and speed scanning via galvanometer system. In this way resulting in its great efficiency on electro-optical conversion. The fact that designating it with air cooling and compact in size enables fiber laser working with stable and quality beam’s translation available on both metal and some of non-metallic materials etc.

Technical Parameters

|

Model |

ML- MF- TY- BX- HWXX |

|

Laser Power |

20W/ 30W/ 50W |

|

Laser wavelength |

1064nm |

|

Repeating Frequency |

20-200KHZ |

|

Beam Quality |

M²<1.2 |

|

Marking Range |

70mm x 70mm ~ 300mm x 300mm(Optional) |

|

Marking Speed |

≤7000mm/s |

|

Min.Character |

0.15mm |

|

Repeatability Accuracy |

±0.002 |

|

Power Supply |

220V / 50-60Hz |

|

Consume Power |

800W |

|

Cooling Way |

Built-in air cooling |

Core Features

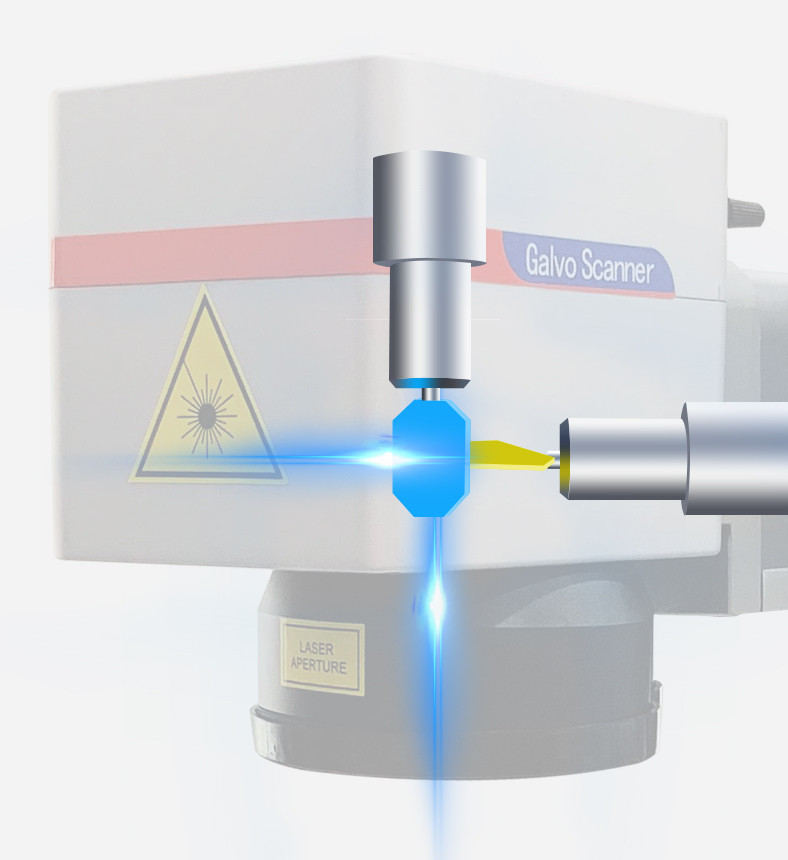

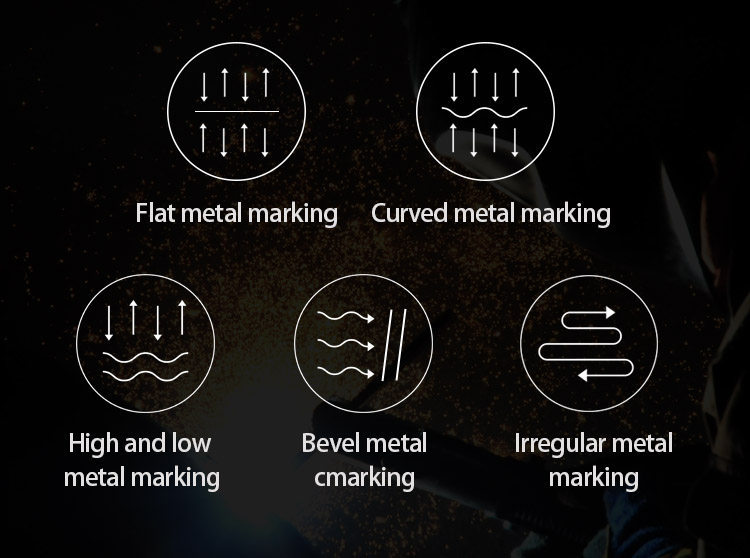

The optical fiber laser is used to output the laser, and then the marking function is realized through the high-speed scanning galvanometer system, so that the optical fiber laser marking position accuracy is high and the marking surface is not deformed.

1. It can process a variety of metal and non-metallic materials. In particular, it is more advantageous to mark materials with high hardness, high melting point and brittleness.

2.It is a non-contact processing, no damage to products, no tool wear and good marking quality.

3. The laser beam is thin, the processing consumables are few, and the processing heat affected zone is small.

4. High processing efficiency, computer controlling and automation.

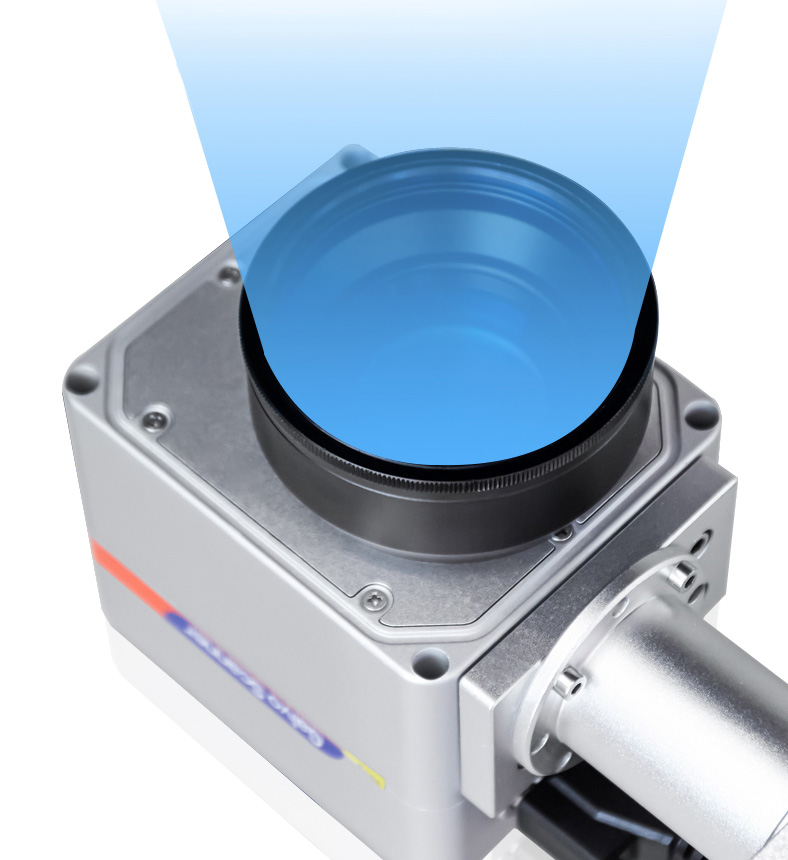

HD transparent marking galvanometer

Highly transparent, clean the lens without impurities, increase the format and see the quality. Only a good lens can mark a good product

High electro-optic conversion efficiency

The laser marking machine system developed by using fiber lasers at home and abroad has good output beam quality, high reliability and electro-optic conversion efficiency

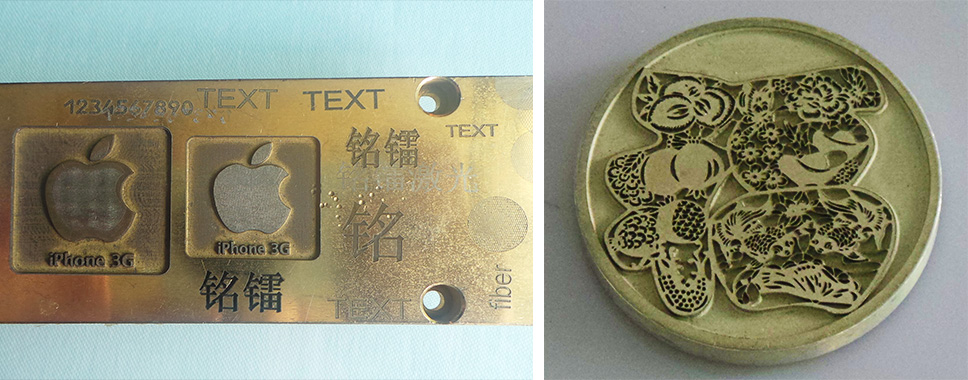

1. Surface mark: It is ideal when marking on coatings without penetrating through, such as chrome, nickel, gold, and silver etc.

2. Deep engraving: Utilizing a high power laser this process vaporizes a material to engrave into the base metal.Most common in plastic injection molds, Jewelry making, and stamping dies.

3.Ablation: Removing surface treatments (i.e. plating, and coatings of paint) to create translucent back round without damaging the base material, widely used in backlit material processing such as backlit buttons.

Application Scenarios

Videos and News for this product

How to clean the welding spot?

on Apr 21,2022

How to clean the welding spot?

on Apr 21,2022

How to clean the welding spot?

on Apr 21,2022