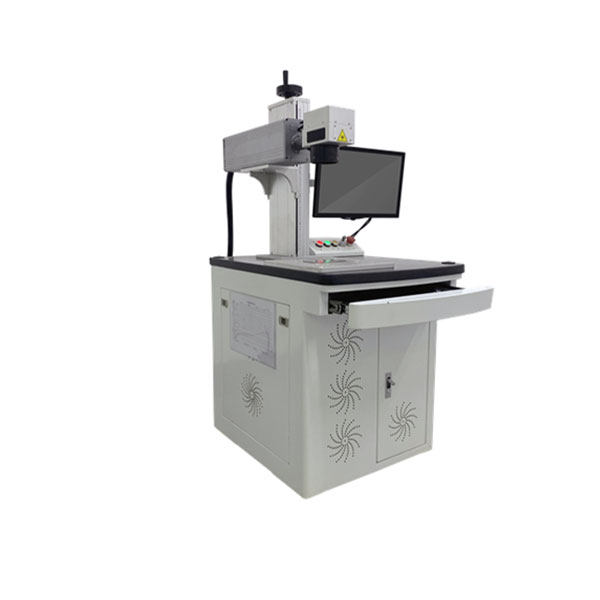

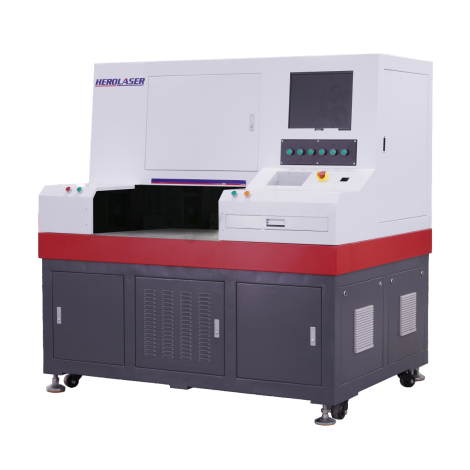

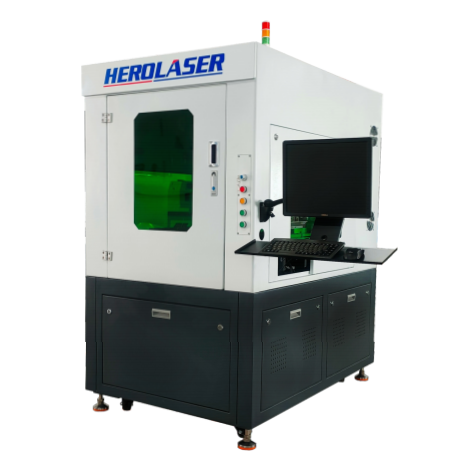

3D Fiber Laser Marking Machine

Product Introduction

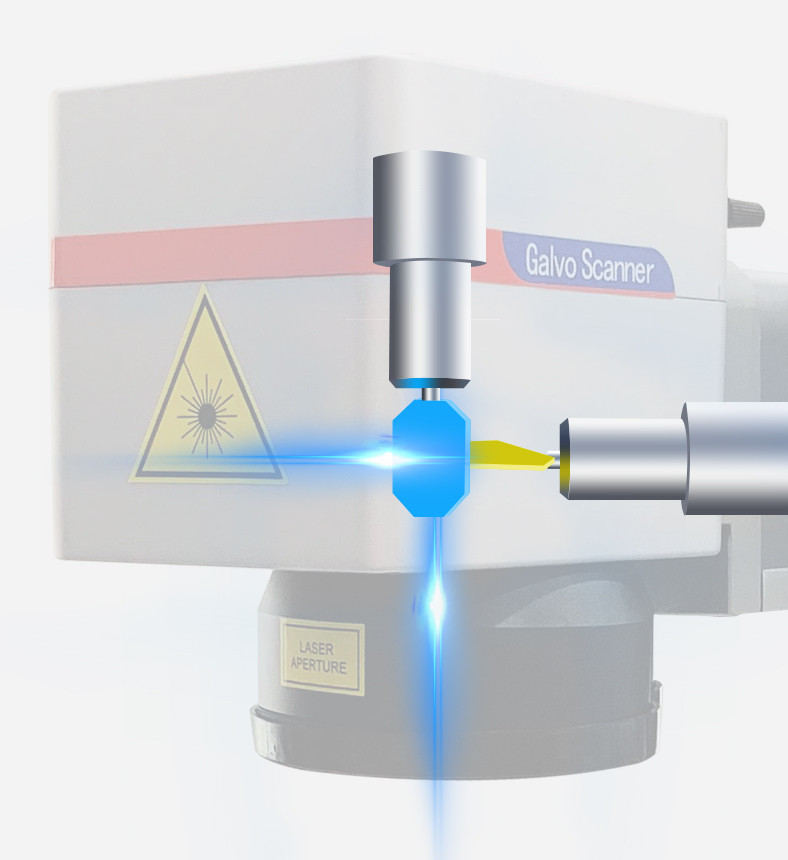

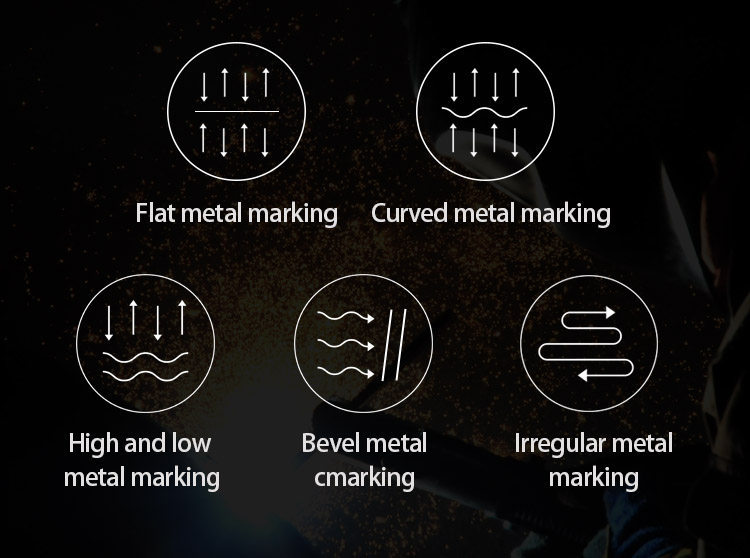

The 3D laser marking machine launched by Herolaser continues to use imported German IPG fiber lasers, under the premise of continuing to maintain excellent beam quality. Using front focusing technology and dynamic focusing, the focused spot is thinner, faster and better. Suitable for large-scale multi-level marking. It can realize laser marking on curved workpieces more accurately, and there is no defocus phenomenon during processing.

Technical Parameters

|

Model |

ML-MF-W20/30/50/100/200 |

|

Laser Power |

20W/ 30W/ 50W/ 100W/ 200W |

|

Laser wavelength |

1064nm |

|

Repeating Frequency |

20-200KHZ |

|

Beam Quality |

M²<2 |

|

Marking Range |

100mm x 100mm(Optional) |

|

Marking Depth |

0.01-2 mm(depend on material and marking time) |

|

Marking Speed |

≤10000mm/s |

|

Min.line Width |

0.01mm |

|

Min.Character |

0.15mm |

|

Repeatability Accuracy |

±0.002 |

|

Power Supply |

220V±10% / 50-60Hz |

|

Weight |

≤200kg |

|

Operating System |

Win98/Win2000/WinXP/Win 7 |

|

Cooling Way |

Built-in air cooling |

|

Control Interface |

Standard USB |

|

File Format |

All character styles from character store of OS |

|

Laser Type |

Pulse |

Core Features

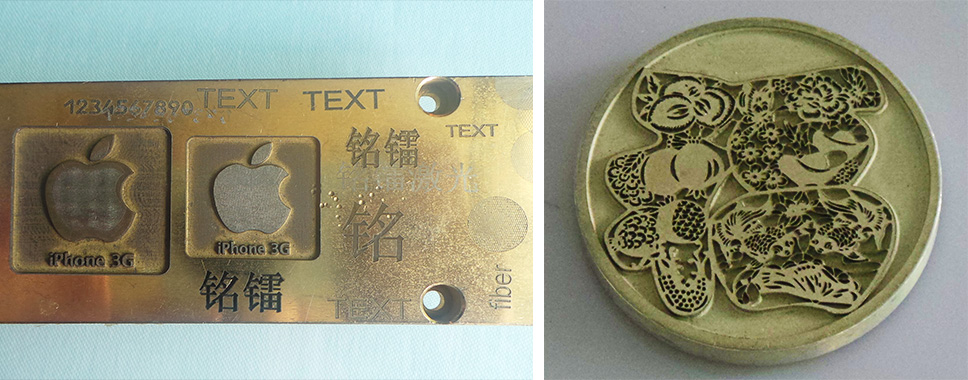

1. Excellent beam quality: Adopt Germany IPG, and other reliable advanced fiber laser source, beam quality is much better than traditional solid-state laser, focused spot diameter less than 20um, divergence angle is 1/4 of diode-pumped laser. Especially suitable for precise and excellent marking.

2. Low cost: The highest electrical/ optical conversion rate is up to 30%, the whole power consumption is less than 500W, this is 1/10 of lamp-pumped solid-state laser marking machine, save much of energy cost.

3. Maintenance-free: laser source no need of any maintenance, also no need adjust or clean the lens.

4. Long term service life of the laser source: fiber laser marking machine uses a laser diode as the pump source, the average service time can up to 100,000 hours.

5. High marking speed: The marking speed is over 3 times of first and second generation of laser markers.

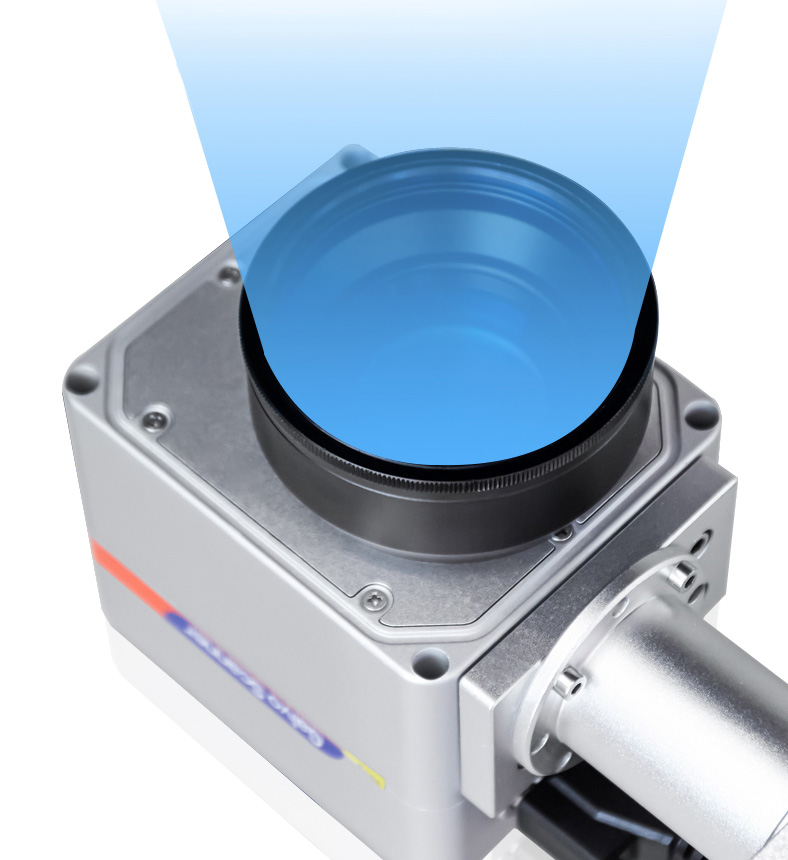

HD transparent marking galvanometer

Highly transparent, clean the lens without impurities, increase the format and see the quality. Only a good lens can mark a good product

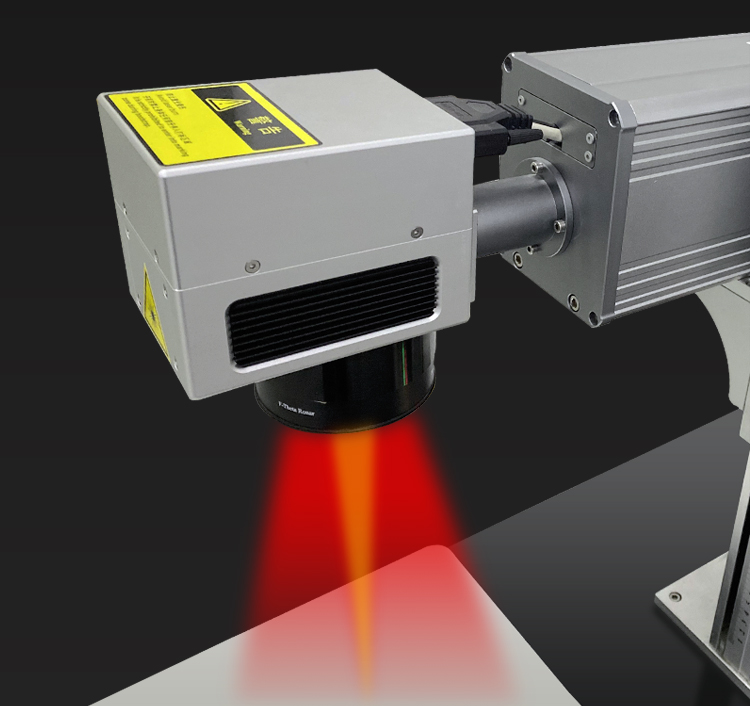

High electro-optic conversion efficiency

The laser marking machine system developed by using fiber lasers at home and abroad has good output beam quality, high reliability and electro-optic conversion efficiency

1. Surface mark: It is ideal when marking on coatings without penetrating through, such as chrome, nickel, gold, and silver etc.

2. Deep engraving: Utilizing a high power laser this process vaporizes a material to engrave into the base metal.Most common in plastic injection molds, Jewelry making, and stamping dies.

3.Ablation: Removing surface treatments (i.e. plating, and coatings of paint) to create translucent back round without damaging the base material, widely used in backlit material processing such as backlit buttons.

Application Scenarios

Videos and News for this product

Laser Marking Machine

on Apr 21,2022

Laser Marking Machine

on Apr 21,2022

Laser Marking Machine

on Apr 21,2022

Comparison of laser marking and other processes

|

Laser Marking | Inkjet printing | Silk Screen | Labelling | MechanicalTop Punch | Put Up a Sign | ||

| Material | Metal, plastic, glass, etc. | Metal, plastic,etc. | not limited | not limited | Metal | not limited | ||

| Process Method | Non-Contact | Contact | Contact, Prepare a screen printing screen in advance | paste | Contact | binding | ||

| Processing Efficiency | One time molding | One time molding | Secondary processing required | Secondary processing required | Permanent mark | Easy to lose | ||

| Adhesion Strength | permanent identification | Easy to fall off and easy to erase | permanent identification | easy to fall off | Easy to oxidize | Easy to contaminate and discolor | ||

| Anti-damage and Anti-fouling | Waterproof and oil proof | Easy to oxidize | Easy to contaminate and discolor | Easy to contaminate and discolor | Easy to accumulate dust | Easy to accumulate dust | ||

| Environmental Friendly | Environmental friendly | Not environmentally friendly | Not environmentally friendly | Not environmentally friendly | One time molding | Requires manual secondary processing | ||

| Area Requirement | Marking anywhere | Requires a relatively large area | Requires a relatively large area | Requires a relatively large area | Requires a relatively large area | Requires a relatively large area | ||

| Consumable | No consumable | Ink consumable | printing screen and ink | label stickers | change punch needle frequently | Sign Consumable | ||

| Graphical text Change | Change as you wish | easy to change | Not easy to change | Not easy to change | Not easy to change | Not easy to change | ||

| Bar-code Gun Identification | High contrast and easy to identify | Contrasting and identifiable | easy to identify | easy to identify | no contrast,difficult to identify | easy to identify | ||

| Operating Cost | long-term continuous investment | long-term continuous investment | long-term continuous investment | long-term continuous investment | long-term continuous investment | long-term continuous investment |

Laser processing has good effect, improves production efficiency, saves manpower and a lot of consumables, and is also safer and more environmentally friendly

HEROLASER Intelligent Laser Processing Equipment Product Catalog

For bulk purchases or customized products, please contact online customer service, or leave a message.

You can also send email to sales@herolaser.net.