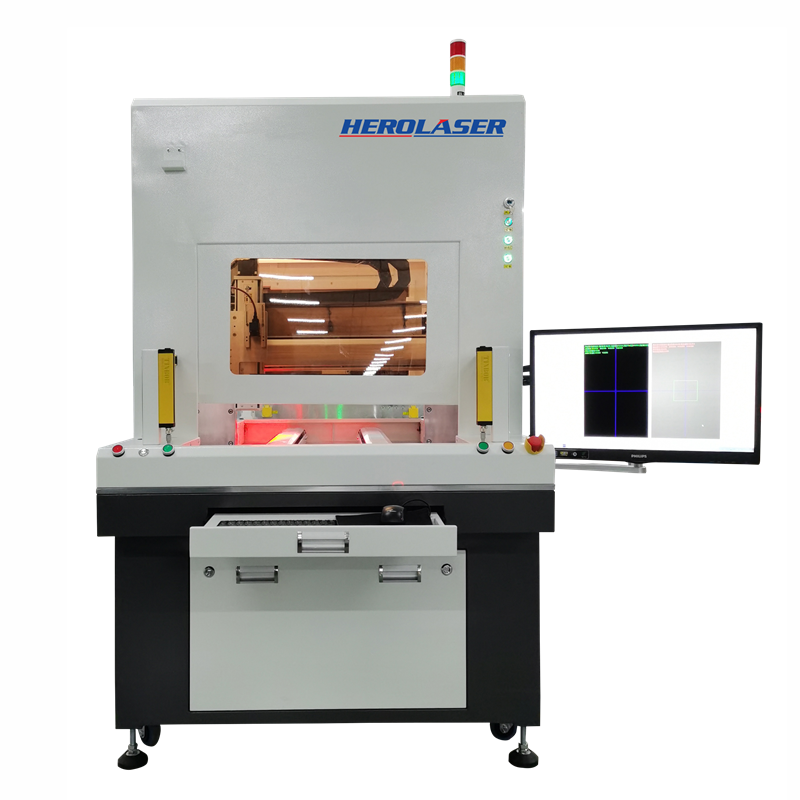

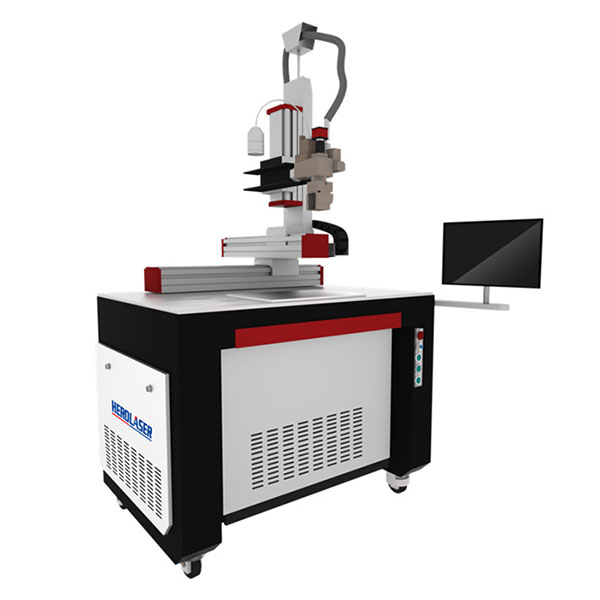

Double station constant temperature laser soldering machine

Product Introduction

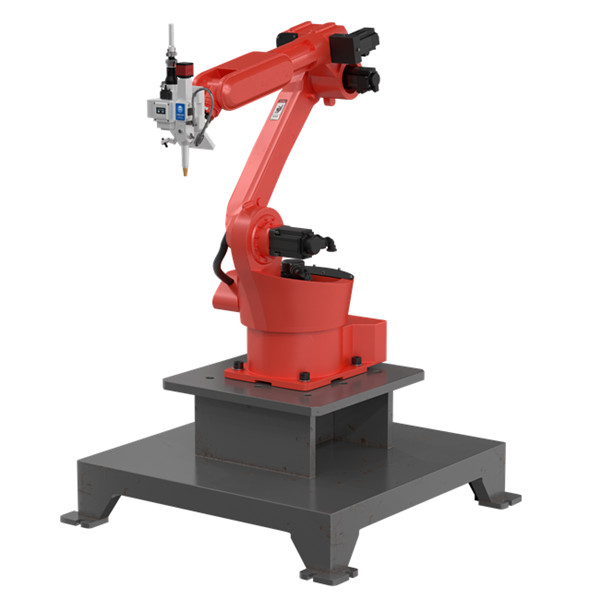

The equipment has multiple working modes and automatic wire feeding system or automatic precision solder paste dispensing device to perfectly solder in different occasions. For certain precision products that cannot process with reflow soldering and wave soldering machine, laser soldering machine will be your reliable option to solder your products given the characteristics of stable structure, cost-effectiveness, high efficiency of soldering and numerical control technology.

|

Technical Parameter |

||

|

No. |

Item |

Parameter |

|

1 |

Model | ML-WS-XF-ZD2-HW80 |

|

2 |

Laser power | 60W-200W |

|

3 |

Laser type | semiconductor |

|

4 |

Focus focal length | 80/125/160mm(optional) |

|

5 |

Tmperature control range | 60°C-400°C |

|

6 |

Temperature System Accuracy | ±( 0.3% reading + 2°C) (ambient temperature 23±5°C) |

|

7 |

GPS | ICoaxial CCD monitoring and

spot tin CCD positioning |

|

8 |

Equipment size | 1100mm*1450mm*1750mm |

|

9 |

Welding range | 250mm*250mm(single working station) |

|

10 |

Feeding stroke | 1000mm |

|

11 |

Number of motion axes | 6 axes(X1 Y1 Z1/X2 Y2 Z2) |

|

12 |

Repeatability | ±0.02mm |

|

13 |

Dust removal system | Automatic soot purification system |

|

14 |

Total Weight | 350Kg |

|

15 |

Total power | ≤2.5KW |

Core Features

1. Adopt semiconductor laser, working in non-contact processing way.

2. No consumption of soldering iron tip, running in low cost and simple maintenance.

3. Visual positioning solder point via Dual vision application and CCD monitoring system.

4. Laser is processing under constant temperature via internal closed-loop feedback of real-time temperature monitoring.

5. The welding spot can be adjusted to meet different soldering sizes.

6. Deploy a smoke purifying system to timely remove burning residue from combustion.

7. Optional to switch between single station and Double station mode.

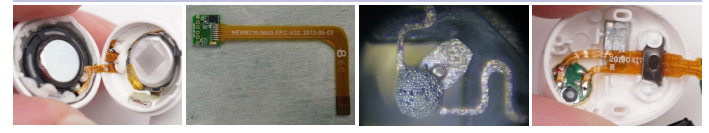

Sample Display