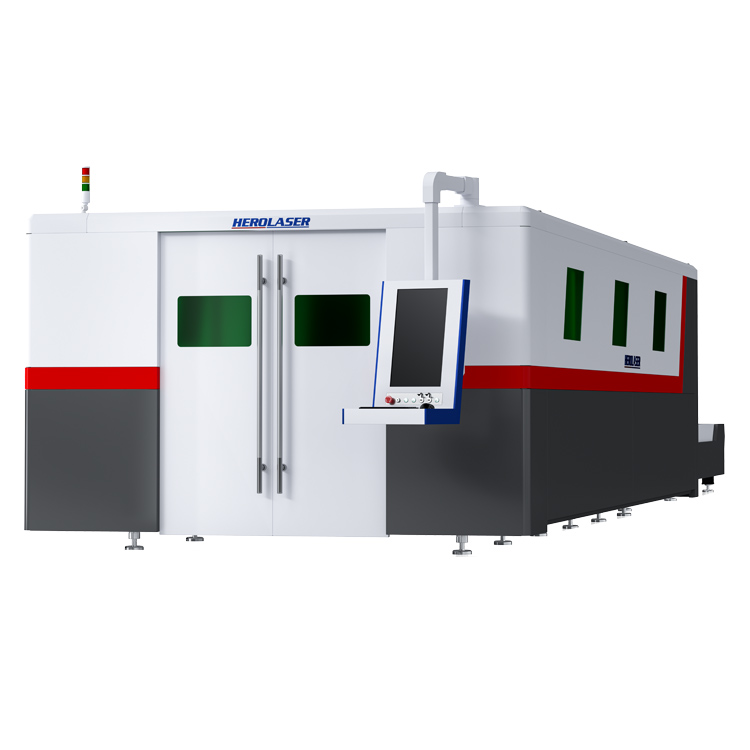

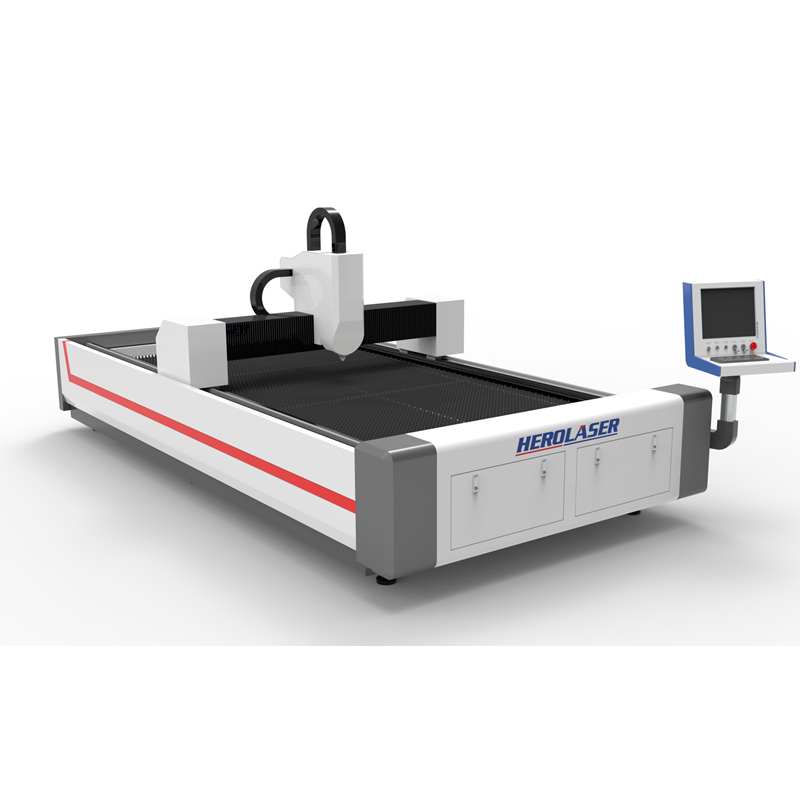

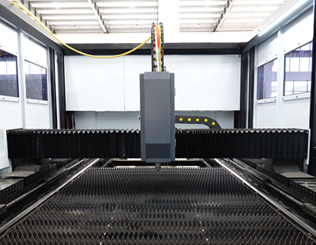

Laser Cutting Machine For Metal Sheet/Plate (ML-CB-3015FB )

Product Introduction

ML-CF-3015FB The sheet metal laser cutting machine adopts two-head mutual-moving laser cutting, and the processing area is large. The negative pressure crawler working platform is equipped with left and right feeding and rewinding devices, which enables unwinding, cutting and rewinding in one go, which greatly reduces the time between procedures , Improve work efficiency and processing output. As a new type of cutting machine, its work efficiency is often 2-10 times that of traditional cutting machines.

Technical Parameters

Core Features

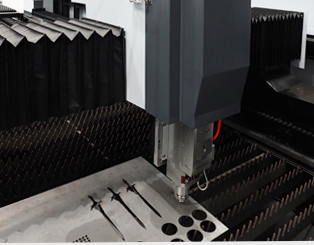

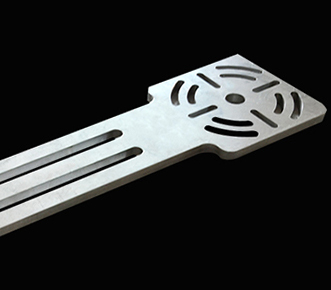

1. Basically 0 error, the cutting surface is smooth and flat

2. Gear and rack drive, cutting and forming at one time

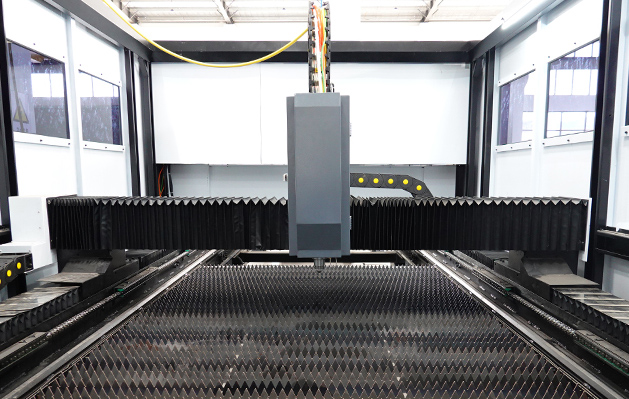

3. Negative pressure crawler platform, integrated unwinding, cutting and receiving

4. Low power consumption, basically maintenance-free later

5.The cutting section of the plate is smooth without burrs, slag, no blackening, and no yellowing, which can accurately achieve various Cutting of complex graphics

1. Mutual movement laser cutting

Adopt two-side moving laser cutting, the processing area is large, high precision and fast cutting

2. Smart large screen operation

Intelligent operating pipe cutting system, easy-to-use interface, fatal operation to improve efficiency, built-in graphic database, no need for manual simple programming.

3. Auto-sensing laser cutting head

High-speed idle, large robot, fast cutting response, corners are not easy to burn, the cutting head is in contact with the surface of the material, ensuring that it will not be perfect

4. Longmen dual-drive structure

Using rack and pinion dual drive transmission structure, high stability, high height, light weight, dynamic response

Application Scenarios

Suitable for vehicle and ship transportation, door and window processing, hardware accessories, metal crafts, kitchen utensils, etc.

Videos and News for this product

Laser Cutting Machine

on Apr 21,2022

Laser Cutting Machine

on Apr 21,2022

Laser Cutting Machine

on Apr 21,2022