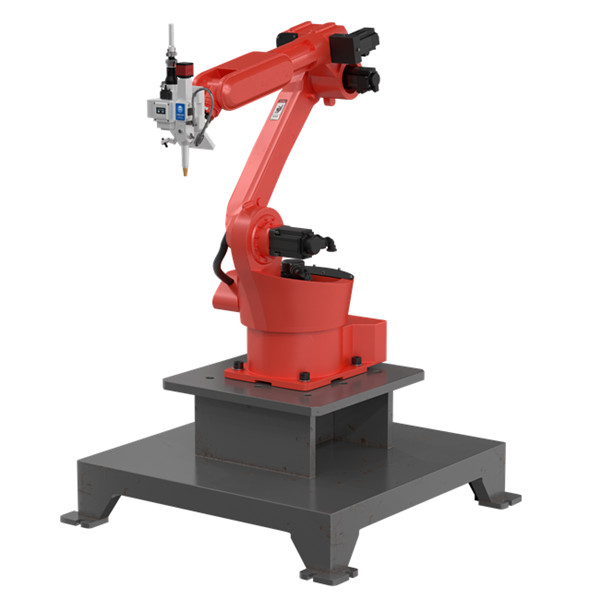

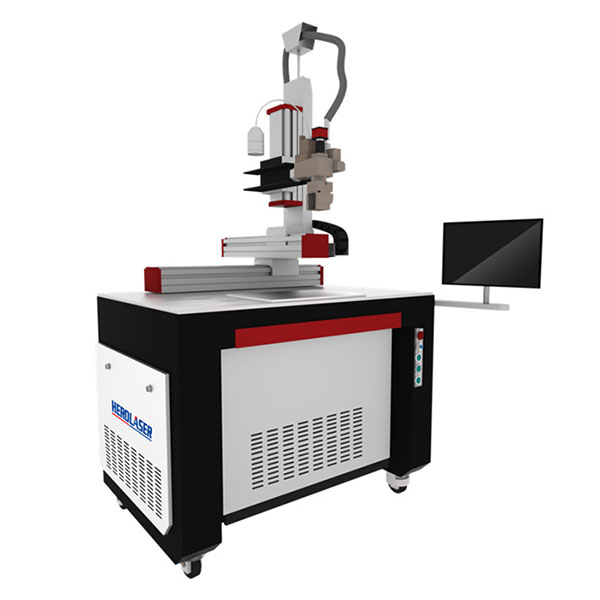

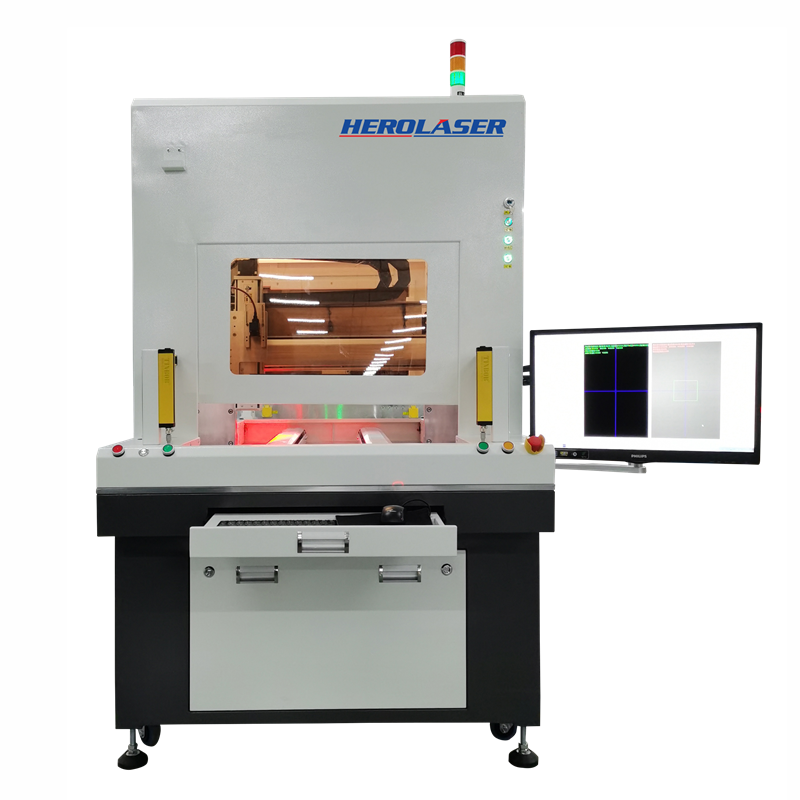

Mould Repairing YAG Laser Welding Machine

Product Introduction

Herolaser mould repairing laser welding machine series are specialized for the mold industry works, this model dedicated to replacing the traditional argon welder for repairing precision molds. All the key components of this machine are imported. The software operating interface use large LCD screen and display multi-languages interface, it is simple and easy to use for operator. Multiple presetting operating mode, also can program by users, permanent memory function, applicable to a variety of materials.

Equipped with special microscope observation system, magnification 10x; There is a high-speed electronic filter protection device to protect the operator's eyes from laser damage, alleviate the operator's eye fatigue and improve the working efficiency

The synchronous argon protection system with internal microcomputer control can prevent the weld from being oxidized and make the welding more firm and beautiful; Argon can be saved to the greatest extent by adopting synchronous control with laser emission

The water tank of robot laser welding machine can heat and cool the machine, and monitor the water temperature in real time. It has constant temperature / circulation mode

The laser host cabinet can clearly observe the product positioning and welding effect according to the red light indication

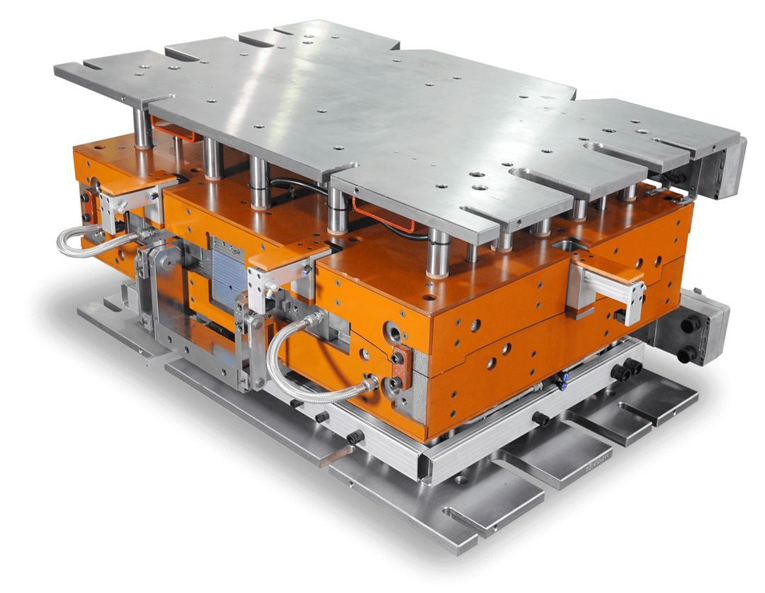

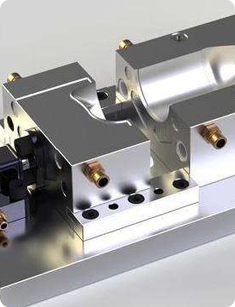

The main machine workbench and the place where the welding workpiece is placed are convenient for the laser to weld the workpiece

Technical Parameters

|

MODEL: |

ML-WY-BP-DB-W200 |

ML-WY-BP-DB-W400 |

|

3-axis stroke of work bench |

X=300mm,Y=200mm(X、Y can be adjusted manually and z-axis can be lifted) |

|

|

Bearing of work bench |

≤200KG |

|

|

Power supply |

220V±10%/50Hz Or 380V±10%/50Hz |

|

|

Laser parameters |

||

|

Laser type |

Nd:YAG pulse |

|

|

Adjusting range of light spot |

0.1~0.3mm |

|

|

Size of light spot |

0.2-3.0mm |

|

|

Laser wavelength |

1064nm |

|

|

Pulse width |

0.5~25ms |

|

|

Maximum laser power |

200W |

400W |

|

Pulse frequency |

≤50Hz |

|

|

Laser output focus length |

80mm/100mm/120mm(optional) |

|

|

Laser cooling |

Water cooling |

|

|

Observing system |

Microscope (360° adjustable) |

|

|

Protection gas |

One line (xenon) |

|

|

Solder parameter |

||

|

Welding wire diameter |

0.1mm~0.8mm |

|

Core Features

1. Heat affected zone is small, little deformation for precision molds.

2. Welding depth is large, welding firmly. Sufficient fusion, no repairing traces. No dimple phenomena at combining position of projection parts and bulge part of molten pool soluble material.

3. Low oxidation rate, the color of the processing parts is intact.

4. No stomata or sand hole disappeared after welding.

5. The welding parts can be processed, especially suitable for polishing requirements of the mold repair.

6. The processing parts can reach to 50 to 60 Rockwell hardness.

No deformation of welding die

The heat affected area is small, which will not lead to the deformation of the precision die, and there is no depression at the joint between the convex part of the molten material in the molten pool and the matrix.

● The oxidation rate is low and the workpiece will not change color after welding

● The heating area is small, and the machined parts will not deform

● There will be no pores or trachoma after welding

● After welding, it can be etched without affecting the effect

Application Scenarios

Mold industry

Metalworking

Machinery manufacturing

Videos and News for this product

Laser Welding Machine

on Apr 21,2022

Laser Welding Machine

on Apr 21,2022

Laser Welding Machine

on Apr 21,2022