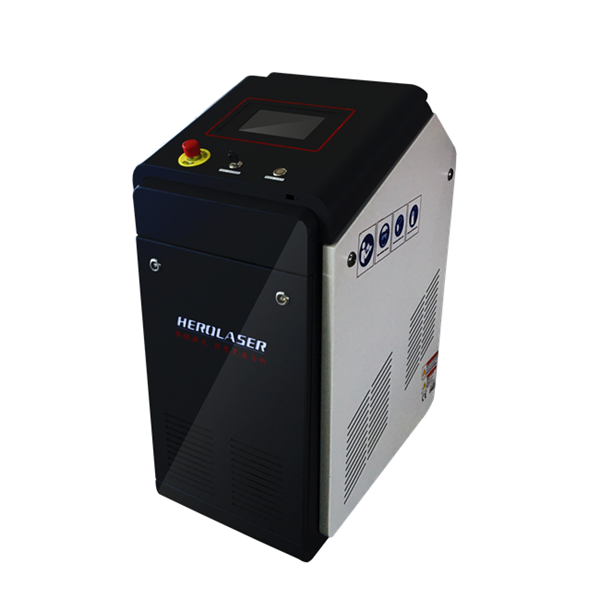

Welding Spot Laser Cleaning Machine

Product Introduction

Laser cleaning Machine is a new generation of high-tech products for surface cleaning. Easy to install, manipulate and automate. Simple operation, turn on the electricity, turn on the equipment, then you can carry out chemical-free, media-free, dust-free, water-free cleaning, automatic focusing, laminated surface cleaning, cleaning surface cleanliness and other advantages, can remove the object surface resin, oil, stains, dirt, embroidery turbidity, coating, plating, paint.

Technical Parameters

|

Equipment Type |

Welding Spot Laser Cleaner (Standard Type) |

|

|

Model Code |

SS |

|

|

Laser Type |

Domestic (H)-pulsed lasers |

Imported (I) Pulsed Lasers |

|

Laser wavelength |

1064 nm |

|

|

Cooling method |

air cooling |

|

|

Fiber cable length |

3 to 5M (customizable) |

|

|

Laser power |

20~100W |

|

|

Supply voltage |

AC~220V 50/60Hz |

|

|

Whole machine power |

≤500W |

|

|

Cabinet dimensions |

785*436*1061mm |

|

|

Weight of the whole machine |

85kg |

|

|

Handheld head weight |

Standard model 1.6kg |

|

|

Working temperature |

5 ~ 40 °C |

|

Core Features

1. First high power fiber laser cleaning machine in China.

2. Non-contact cleaning,can be no damage to workpiece.

3. Precision positioning, selective cleaning, desired cleaning area can be applied to the workpiece.

4. No need chemical detergent, no consumable. Safe & environment-friendly.

5. Easy to operate, either portable or equipped with robot for automatic cleaning.

6. High cleaning efficiency, time-saving.

7. Stable laser cleaning system, free maintenance.

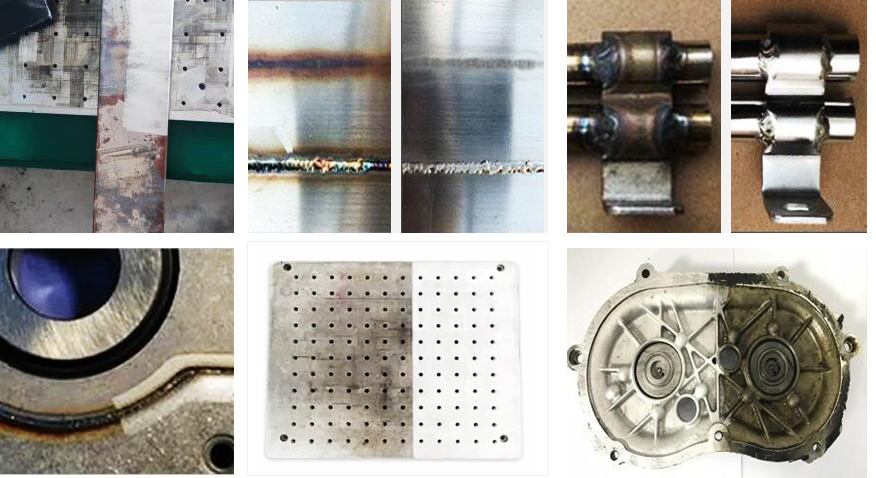

Application Scenarios

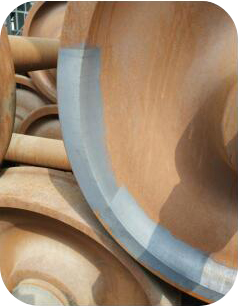

Suitable for cleaning welded surfaces of steel and aluminium,as a pre-treatment for welded surfaces, which is after welding.

Applications include the automotive industry, precision tool production, shipbuilding and other industries.

Videos and News for this product

How to clean the welding spot?

on Apr 21,2022

Laser Cleaning Machine

on Apr 21,2022

Laser Cleaning Machine

on Apr 21,2022