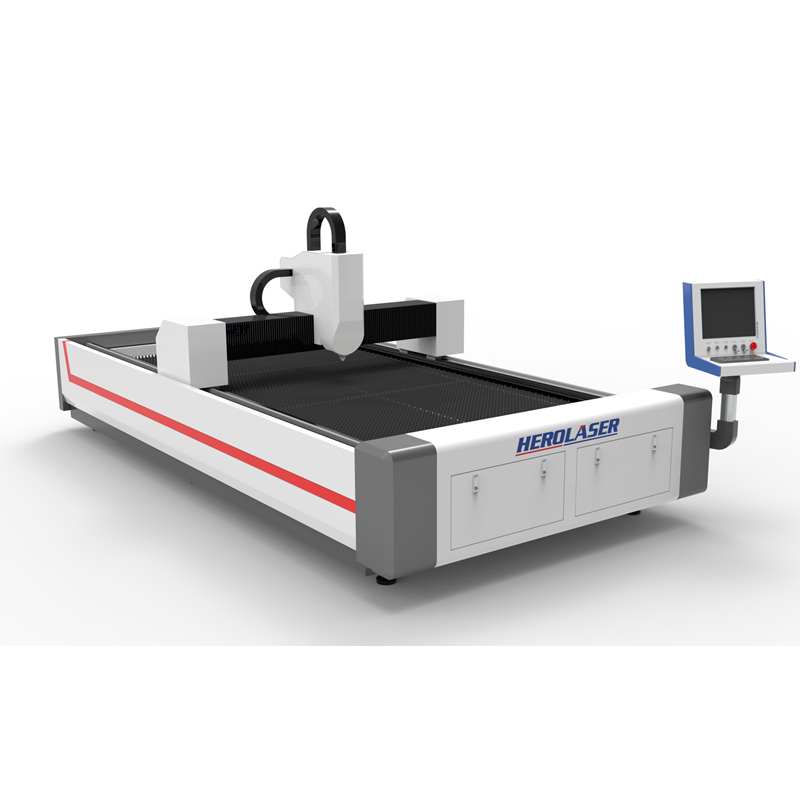

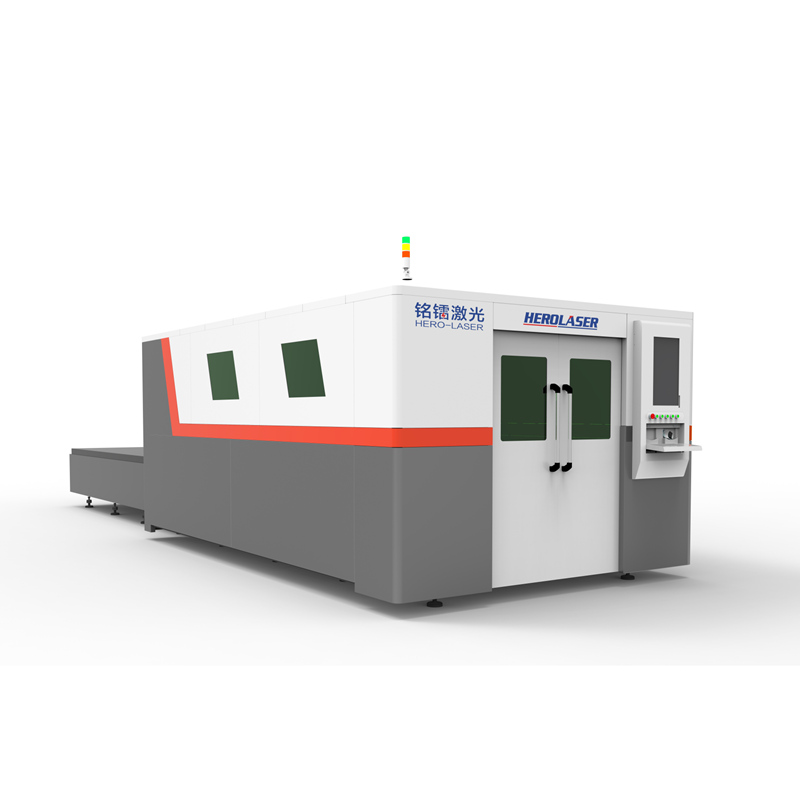

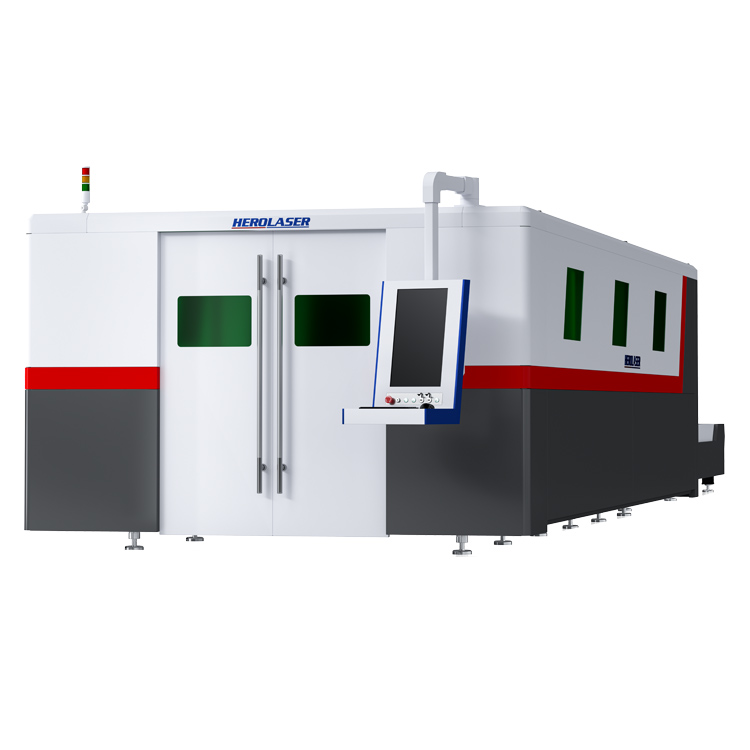

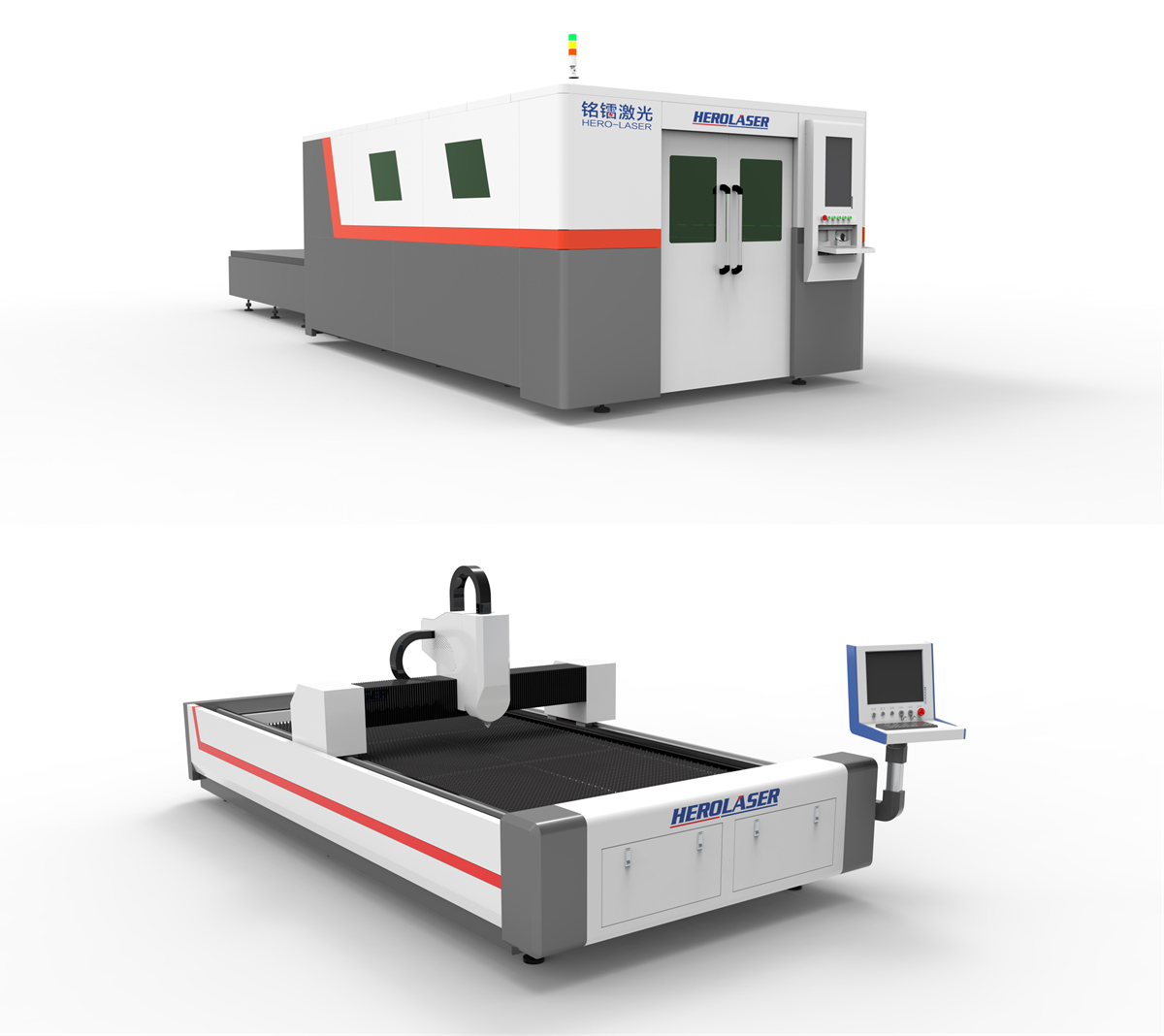

Fiber Laser cutting machine (3015 series)

Product Introduction

The 3015 series laser cutting machine is a fiber laser cutting machine with advanced structural design and excellent machine performance. It adopts the world-class numerical control system and fiber laser. The gantry-type double-drive structure is applied, the integral welded base is adopted, and the rack-and-pinion transmission structure is adopted. Greatly improve processing efficiency; visual nesting, close fit, saving materials. Advanced technology can speed up your company's new product development and recover your equipment investment costs as quickly as possible.

Technical Parameters

| Name | Medium powerCB switchingplatform series | Medium powerCB singleplatform series | High PowerCZ SwitchPlatform Series | High PowerCZ SinglePlatform Series | High PowerCZ SinglePlatform Series |

| Model | ML-CB-3015FB | ML-CB-3015T | ML-CZ-3015FB | ML-CZ-3015T | ML-CF-3015FB |

| Cutting Range | 3000*1500mm | 3000*1500mm | 3000*1500mm | 3000*1500mm | 3000*1500mm |

| Power Range | >3000W | >3000W | 3000W-6000W | 3000W-6000W | 12000W-20000W |

| X/Y Max Speed | 100m/min | 100m/min | 110m/min | 110m/min | 120m/min |

| XY Max Acceleration | 0.8G | 0.8G | 1.0G | 1.0G | 1.5G |

| Position Accuracy | ±0.03mm/m | ±0.03mm/m | ±0.03mm/m | ±0.03mm/m | ±0.03mm/m |

| Repeatability | ±0.02mm | ±0.02mm | ±0.02mm | ±0.02mm | ±0.02mm |

| Weight | 4.5T | 2.4T | 6.8T | 3.6T | 7.5T |

| Dimensional size | 8100*2650*2200mm | 4800*2250*1800mm | 8100*2650*2200mm | 4800*2250*1800mm | 8100*2650*2200mm |

Core Features

1. Basically 0 error, the cutting surface is smooth and flat

2. Gear and rack drive, cutting and forming at one time

3. Negative pressure crawler platform, integrated unwinding, cutting and receiving

4. Low power consumption, basically maintenance-free later

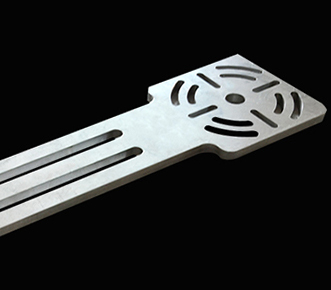

5.The cutting section of the plate is smooth without burrs, slag, no blackening, and no yellowing, which can accurately achieve various Cutting of complex graphics

6.The laser beam has good quality, high stability, low power consumption and long life;

7.Equipped with emerging technology automatic focusing cutting head, simple and intelligent operation;

8.Graphical trajectory can be directly drawn or edited in the software processing system;

9.The slit is narrow, the heat affected zone is small, the local deformation of the workpiece is extremely small, and there is no mechanical deformation;

10.High-end configuration, powerful and cost-effective.

Application Scenarios

Widely used in sheet metal processing, advertising sign making, machinery parts, kitchen utensils, metal handicrafts, saw blades, hardware and other industries. It can also be used for cutting carbon steel, stainless steel, aluminum alloy, copper, titanium and other metals.

Videos and News for this product

Laser Cutting Machine

on Apr 21,2022

Laser Cutting Machine

on Apr 21,2022

Laser Cutting Machine

on Apr 21,2022