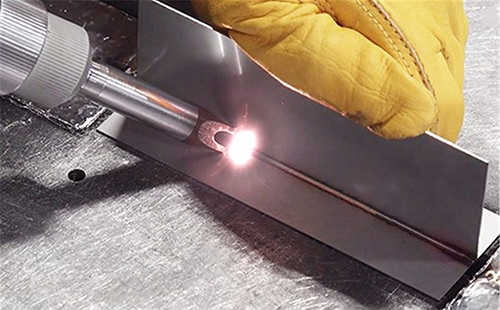

Melemo ea mochini oa welding oa laser o ts'oaretsoeng ka kichineng le indastering ea ho hlapela

Bophelong ba rona ba letsatsi le letsatsi, re ke ke ra phela ntle le kichine le ntloana.Kichine ea sejoale-joale le kamore ea ho hlapela e kenyelletsa siling, thepa ea kichineng le ea ho hlapela, khabinete ea bohlokoa, khabinete ea kamore ea ho hlapela, lisebelisoa tse bohlale, hitara ea kamore ea ho hlapela, mochini o kenyang moea, sistimi ea mabone, setofo se kopaneng le lisebelisoa tse ling tse amanang le kichine le ntloana.Mokhoa oa setso oa ho tjheseletsa oa kichineng le indastering ea lisebelisoa tsa kamore ea ho hlapela ke haholo-holo argon arc welding.Mokhoa ona oa welding o na le mefokolo e mengata, joalo ka ho hira basebetsi ka thata, taolo e thata ea matsoho, litšenyehelo tse phahameng tsa basebetsi, sekhahla sa chai e tlase, polokeho e tlase, botle bo tlase, boits'oaro bo tlase, joalo-joalo.Laser tjheseletsa ka ka katleho rarolla mathata ana.

Melemo ea ho tjheseletsa ka letsoho ka kichineng le indastering ya disebediswa tsa ho hlapela

1. Litsenyehelo tse phahameng tsa basebetsi: meputso ea li-welders tse hōlileng tsebong ka kichineng, ntloaneng le indasteri ea lisebelisoa tsa ntlo li feta li-yuan tse 10000, 'me ha ho na li-welders tse seng kae fekthering e' ngoe le e 'ngoe e hōlileng.Ha nako e ntse e ea, litšenyehelo tsa basebetsi ke litšenyehelo tse kholo bakeng sa likhoebo.

2. Ts'ebetso e tlase ea welding: palo ea li-welders fekthering e lekanyelitsoe, 'me palo ea li-welders tse cheselitsoeng letsatsi le leng le le leng e lekanyelitsoe, e leng se lebisang ho palo e lekanyelitsoeng ea lihlahisoa tse hlahisoang ke fektheri letsatsi le leng le le leng.Ha nako e ntse e ea, e lebisa katlehong e tlaase le ho sitoa ho boloka matla a tlhahiso.

3. Tšireletseho e tlaase: ho tjheseletsa ka letsoho ho sebelisoa haholo-holo ke batho, e leng se tla hlahisa mocheso o phahameng nakong ea ho tjheseletsa.Ts'ebetso e fosahetseng e tla lematsa matsoho le mahlo a motho ea sebetsang.

4. Low Aesthetics: ho cheselletsa ka letsoho ho sebelisoa haholo ke li-welders.Li-welders tse fapaneng li na le mekhoa e fapaneng ea ho cheselletsa, e ka lebisang phapanong ea lihlahisoa tse cheselitsoeng.Li-welders tse ling li na le litsebo, 'me lihlahisoa tse cheselitsoeng li tla ba ntle haholo.Li-welders tse ling ha li tloaelehe, 'me lihlahisoa tse cheselitsoeng li ka ba le li-burrs le likoti tse ngata, tse tla ama botle ba lihlahisoa ka kakaretso.

5. Tekanyo e tlase ea boiketsetso: indasteri ea lisebelisoa tsa kichineng le ea kamore ea ho hlapela e laoloa ke ho tjheseletsa ka letsoho, 'me boitšoaro ba basebetsi ha bo laolehe, e leng se etsang hore potoloho ea tlhahiso ea sehlahisoa ka seng e sa laolehe ka ho feletseng.Tekanyo e tlase ea automation

Melemo ea ho tjheseletsa laser ka letsoho ka kichineng le indastering ya disebediswa tsa ho hlapela

1. Fokotsa litšenyehelo tse felletseng: theko ea pele ea theko ea mochini oa welding oa laser ea letsoho e phahame.Bophelo ba ts'ebeletso ea mochini oa welding oa laser oa letsoho o feta lilemo tse 10.Likhoebo tse ling li khutlisitse litšenyehelo nakong ea halofo ea selemo kamora ho reka mochini oa welding oa laser, 'me li maemong a phaello e felletseng ka lilemo tse fetang 9.Esita le haeba mochine oa welding oa laser o tla senyeha nakong ea tšebeliso, o tla ba le litšenyehelo tsa tlhokomelo, tse ka lebelloang.

2. E rarollotse bothata ba polokeho: mochini oa welding oa laser o ts'oaretsoeng ka letsoho ke mochini oa ho tjheseletsa ntle le letsoho, o ntlafatsang polokeho ea basebetsi.

3.Rarolla bothata ba Aesthetics: mochine oa welding oa laser o tšoaroang ka letsoho o sebetsa ka ho feletseng ho ea ka mekhoa e seng e setiloe, 'me lihlahisoa tse cheselitsoeng li na le aesthetics e phahameng le ho tsitsisa ho phahameng.

4. Ts'ebetso e ntlafetseng ea tlhahiso ea lihlahisoa: mochine oa welding oa laser o tšoaroang ka letsoho o sebetsa ho latela mokhoa o behiloeng esale pele, o sa ameheng ke lintho tse ka ntle tse kang basebetsi.Tlas'a maemo a mang, ha ho na bothata bosiu.

5. Ntlafatsa tekanyo ea ho iketsetsa: mochine oa welding laser o tšoaroang ka letsoho o sebetsa ho ea ka mokhoa o hlophisitsoeng, o ntlafatsang haholo tekanyo ea ho iketsetsa.

Ho hlaha ha handheld laser tjheseletsa mochini feela etsa bakeng sa mefokolo ea setso tjheseletsa.Laser e tsoela pele ho ntlafatsoa motheong oa welding laser.Mochini oa welding oa letsoho oa laser o nka mohaho o kopantsoeng o nang le tsamaiso e kopantsoeng ea taolo, tsamaiso ea laser, tsamaiso ea ho pholisa le mekhoa e meng;Sethunya se ts'oaretsoeng ka letsoho se sebelisetsoa ho nkela sebaka sa tsela ea optical e neng e tsitsitse pele, 'me ha ho hlokahale hore ho thehoe lisebelisoa ho tsamaisa tafole ea ho tjheseletsa, e nkang sebaka se senyenyane mme e ka lemoha ho tjheseletsa ka ntle;Hlooho e ts'oaretsoeng ka letsoho e bonolo ebile e bonolo.Ho latela tlhoko ea 'maraka, ho entsoe li-nozzle tse fapaneng tse loketseng ho ts'ehetsa welding, welding, overlap welding, fillet welding le mekhoa e meng ea welding.E loketse bakeng sa tjheseletsa e potlakileng ea tšepe ea carbon, tšepe e sa hloekang, motsoako oa aluminium, motsoako oa titanium, poleiti ea galvanized, poleiti ea zinki ea aluminium, koporo, koporo e khubelu le lisebelisoa tse ling.

Nako ea poso: Apr-12-2022