Hoʻoponopono ʻana i ka Mīkini Welding Laser YAG

Hoʻolauna Huahana

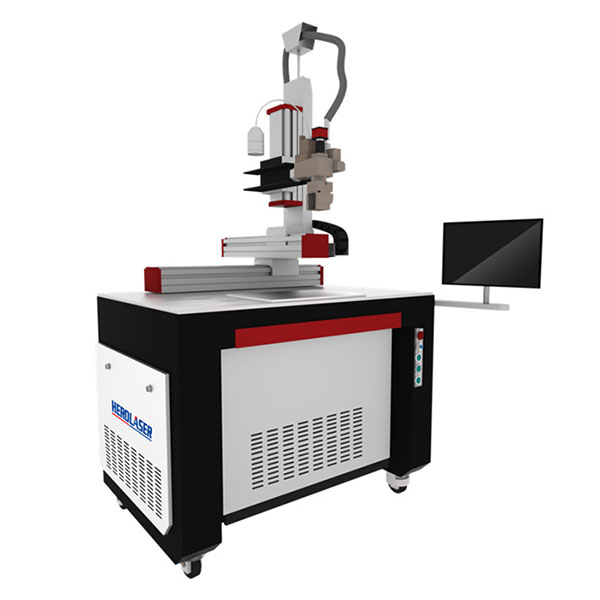

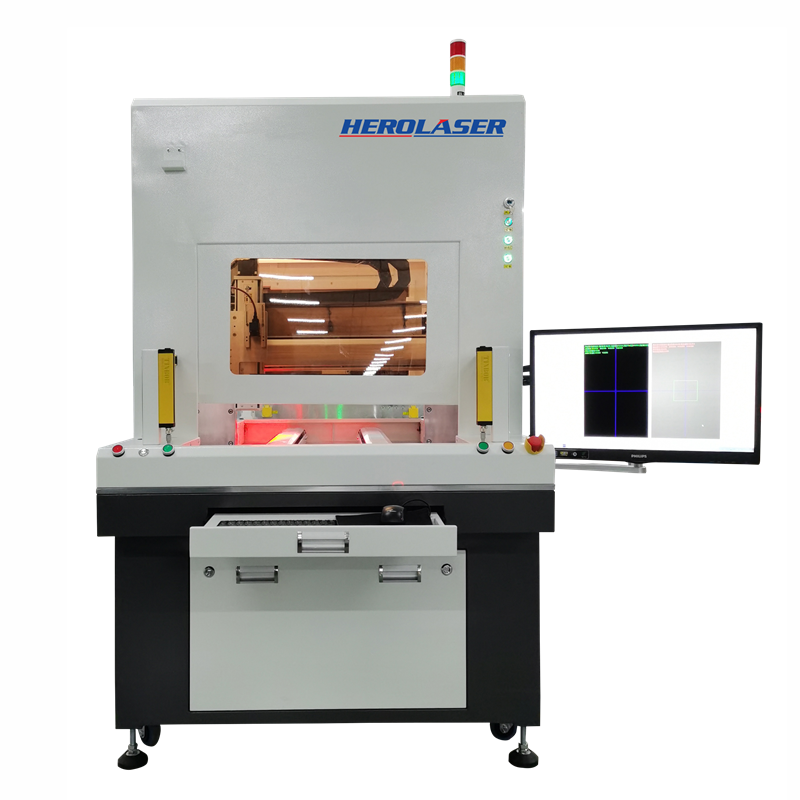

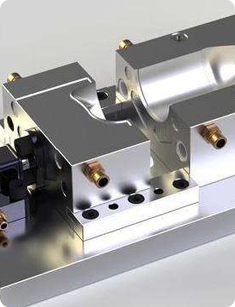

ʻO ka Herolaser mold repairing laser welding machine series he mea kūikawā no ka hana ʻoihana mold, hoʻolaʻa ʻia kēia hiʻohiʻona e hoʻololi i ka welder argon kuʻuna no ka hoʻoponopono ʻana i nā mold precision.Hoʻokomo ʻia nā mea kī a pau o kēia mīkini.Hoʻohana ka polokalamu hana polokalamu i ka pale LCD nui a hōʻike i nā ʻano ʻōlelo he nui, maʻalahi a maʻalahi hoʻi e hoʻohana no ka mea hoʻohana.ʻO ke ʻano hana hana presetting, hiki ke hoʻolālā ʻia e nā mea hoʻohana, hana hoʻomanaʻo mau, pili i nā ʻano mea like ʻole.

Hoʻolako ʻia me ka ʻōnaehana nānā microscope kūikawā, hoʻonui 10x;Aia kahi mea hoʻomalu kānana uila kiʻekiʻe e pale i nā maka o ka mea hoʻohana mai ka pōʻino laser, e hoʻopau i ka luhi o ka mea hana a hoʻomaikaʻi i ka hana hana.

ʻO ka ʻōnaehana pale argon synchronous me ka mana microcomputer kūloko hiki ke pale i ka weld mai ka oxidized a hoʻolilo i ka wili i ʻoi aku ka paʻa a nani;Hiki ke mālama ʻia ʻo Argon i ka nui loa ma ka hoʻohana ʻana i ka mana synchronous me ka hoʻokuʻu laser

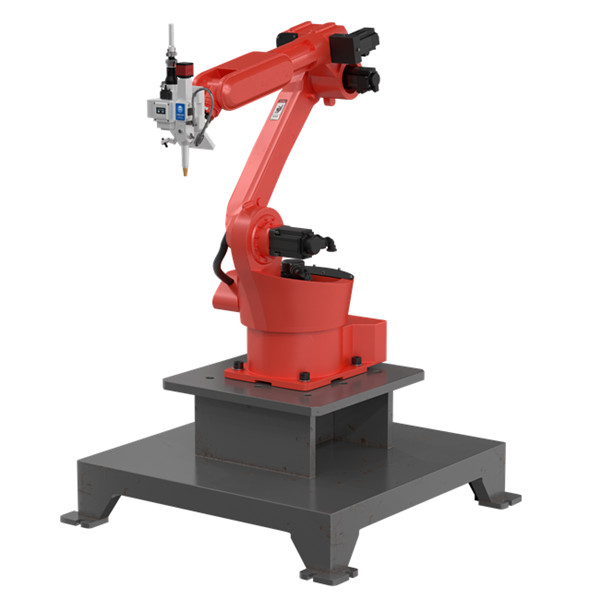

Hiki i ka pahu wai o ka robot laser welding machine ke wela a hoʻomaha i ka mīkini, a nānā i ka mahana o ka wai i ka manawa maoli.Loaʻa iā ia ke ʻano mahana / circulation mau

Hiki ke nānā pono ke keʻena hoʻokipa laser i ka hoʻonohonoho ʻana o ka huahana a me ka hopena welding e like me ka hōʻailona ʻulaʻula

ʻO ka papa hana mīkini nui a me kahi kahi i kau ʻia ai ka mea hana kuʻi he mea maʻalahi no ka laser e wili ai i ka mea hana

Nā ʻāpana ʻenehana

| KĀLĀKAI: | ML-WY-BP-DB-W200 | ML-WY-BP-DB-W400 |

| 3-axis stroke o ka pae hana | X=300mm,Y=200mm(X、Hiki ke hoʻololi ʻia ʻo Y me ka lima a hiki ke hāpai ʻia ka z-axis) | |

| ʻO ke kau ʻana o ka papa hana | ≤200KG | |

| Lako ikehu | 220V±10%/50Hz A i ʻole 380V±10%/50Hz | |

| Nā palena laser | ||

| ʻAno laser | Nd:YAG pulse | |

| Hoʻoponopono i ka laulā o kahi māmā | 0.1~0.3mm | |

| Ka nui o kahi māmā | 0.2-3.0mm | |

| Ka lōʻihi hawewe laser | 1064nm | |

| Pulse laula | 0.5~25ms | |

| Ka mana laser kiʻekiʻe | 200W | 400W |

| Pulse frequency | ≤50Hz | |

| ʻO ka lōʻihi o ka nānā ʻana i ka hopena laser | 80mm/100mm/120mm(koho) | |

| ʻO ka hoʻoluʻu laser | Hoʻoluʻu wai | |

| Pūnaehana nānā | Microscope (360° hiki ke hoʻololi) | |

| kinoea pale | Hoʻokahi laina (xenon) | |

| Palena kuʻina | ||

| Anawaena uwea wiliwili | 0.1mm~0.8mm | |

Nā hiʻohiʻona kumu

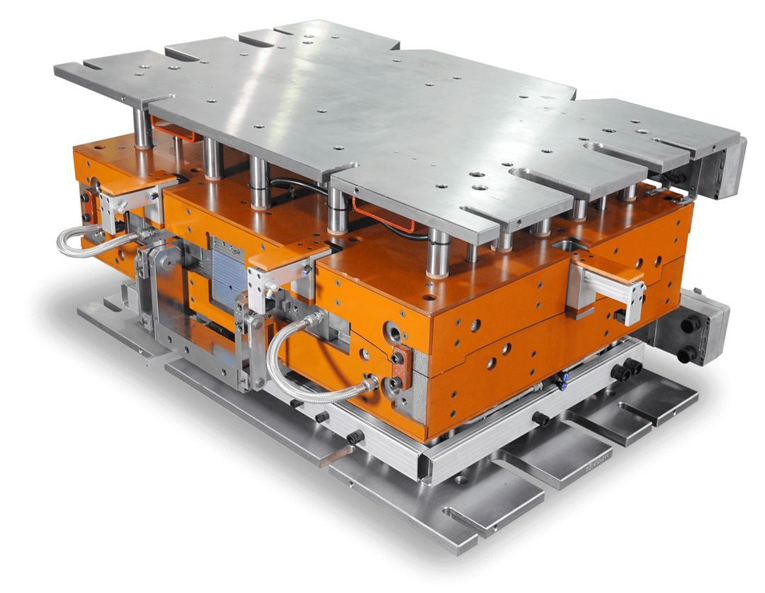

1. He liʻiliʻi ka wahi i hoʻopili ʻia i ka wela, liʻiliʻi deformation no nā molds precision.

2. He nui ka hohonu o ka welding, wili paʻa.ʻAʻole lawa ka hui ʻana, ʻaʻohe wahi hoʻoponopono.ʻAʻohe hanana dimple i ka hoʻohui ʻana i ke kūlana o nā ʻāpana projection a me kahi ʻāpana o ka wai hoʻoheheʻe ʻia.

3. He haʻahaʻa haʻahaʻa haʻahaʻa, ʻo ke kala o nā ʻāpana hana i paʻa.

4. ʻAʻohe stomata a i ʻole lua one i nalowale ma hope o ka wili ʻana.

5. Hiki ke hana i nā ʻāpana kuʻi, kūpono loa i nā koi polishing o ka hoʻoponopono ʻana.

6. Hiki i nā'āpana hana ke hiki i ka 50 a hiki i ka 60 Rockwell pa'akikī.

ʻAʻohe deformation o ka welding make

He liʻiliʻi ka wahi i hoʻopili ʻia, ʻaʻole ia e alakaʻi i ka deformation o ka precision make, a ʻaʻohe puʻuwai i ka hui ma waena o ka convex ʻāpana o ka mea hoʻoheheʻe ʻia i loko o ka wai hoʻoheheʻe a me ka matrix.

● He haʻahaʻa ka helu oxidation a ʻaʻole e hoʻololi ka mea hana i ke kala ma hope o ke kuʻi ʻana

● He liʻiliʻi ka wahi hoʻomehana, a ʻaʻole e deform nā ʻāpana mīkini

● ʻAʻohe pores a i ʻole trachoma ma hope o ke kuʻi ʻana

● Ma hope o ke kuʻi ʻana, hiki ke kālai ʻia me ka ʻole o ka hopena

Nā hiʻohiʻona noiʻi

ʻoihana poʻo

Hana metala

Mea hana mīkini

Nā wikiō a me nā Nūhou no kēia huahana

Mīkini wiliwili Laser

ma ʻApelila 21,2022

Mīkini wiliwili Laser

ma ʻApelila 21,2022

Mīkini wiliwili Laser

ma ʻApelila 21,2022

e noi i ke kumu kūʻai maikaʻi loa

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu