Advantages of handheld laser welding machine in the kitchen and bathroom industry

In our daily life, we cannot live without kitchen and bathroom. Modern kitchen and bathroom includes ceiling, kitchen and bathroom furniture, integral cabinet, bathroom cabinet, smart appliances, bathroom heater, ventilator, lighting system, integrated stove and other kitchen and bathroom related supplies. The traditional welding method of kitchen and bathroom appliance industry is mainly manual argon arc welding. This welding method has many disadvantages, such as difficult recruitment of workers, difficult manual management, high labor cost, low yield rate, low safety, low aesthetics, low degree of automation and so on. Laser welding can effectively solve these problems.

Disadvantages of manual welding in the kitchen and bathroom appliance industry

1. High labor cost: the wages of mature welders in the kitchen, bathroom and household appliances industry are more than 10000 yuan, and there are not a few welders in each mature factory. In the long run, labor cost is a large expenditure for enterprises.

2. Low welding efficiency: the number of welders in the factory is limited, and the number of welders welded every day is limited, which leads to the limited number of products produced by the factory every day. In the long run, it leads to low efficiency and unable to keep up with the production capacity.

3. Low safety: manual welding is mainly operated by people, which will produce high heat during welding. Improper operation will harm the operator's arms and eyes.

4. Low Aesthetics: manual welding is mainly operated by welders. Different welders have different welding methods, which may lead to differences in the products welded. Some welders are skilled, and the products welded will be very exquisite. Some welders are unfamiliar, and the products welded may have many burrs and pits, which will affect the aesthetics of the products as a whole.

5. Low degree of automation: the kitchen and bathroom appliance industry is dominated by manual welding, and the behavior of personnel is uncontrollable, resulting in the production cycle of each product is not completely controllable. Low degree of automation

Advantages of handheld laser welding in kitchen and bathroom appliance industry

1. Reduce the comprehensive cost: the initial purchase cost of handheld laser welding machine is high. The service life of a handheld laser welding machine is more than 10 years. Some enterprises have recovered the cost within half a year after purchasing the laser welding machine, and are in the stage of full profit for more than 9 years. Even if the laser welding machine will be damaged during use, it will incur maintenance costs, which can be expected.

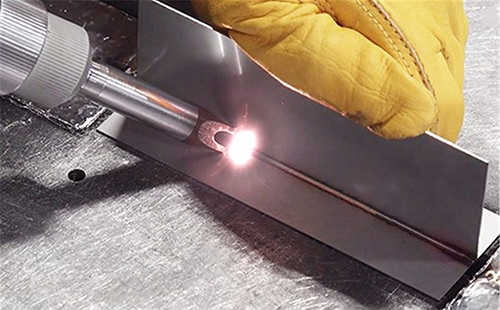

2. Solved the safety problem: the hand-held laser welding machine is machine welding without manual welding, which improves the safety of personnel.

3.Solve the problem of Aesthetics: the handheld laser welding machine works completely according to the preset procedures, and the welded products have high aesthetics and high consistency.

4. Improved product production efficiency: the hand-held laser welding machine works according to the preset procedure, which is not affected by external factors such as operators. Under some conditions, there is no problem at night.

5. Improve the degree of automation: the handheld laser welding machine works according to the preset procedure, which greatly improves the degree of automation.

The emergence of handheld laser welding machine just makes up for the shortcomings of traditional welding. Laser is further developed on the basis of laser welding. The handheld laser welding machine adopts an integrated structure with built-in integrated control system, laser system, cooling system and other mechanisms; The hand-held welding gun is used to replace the previously fixed optical path, and there is no need to set up equipment to deploy the welding table, which takes up a small space and can realize outdoor welding; The hand-held welding head is flexible and convenient. According to the market demand, a variety of suitable welding nozzles have been developed to support spot welding, overlap welding, fillet welding and other welding methods. It is suitable for fast welding of carbon steel, stainless steel, aluminum alloy, titanium alloy, galvanized plate, aluminum zinc plate, brass, red copper and other metals.

Post time: Apr-12-2022